Metal particle detection sensor based on high-frequency high-gradient magnetic field and detection method thereof

A high-gradient magnetic field, detection sensor technology, applied in the size/direction of the magnetic field, magnetic gradient measurement, magnetic field measurement using electromagnetic devices, etc., to achieve the effect of improving detection capability, enhancing detection capability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

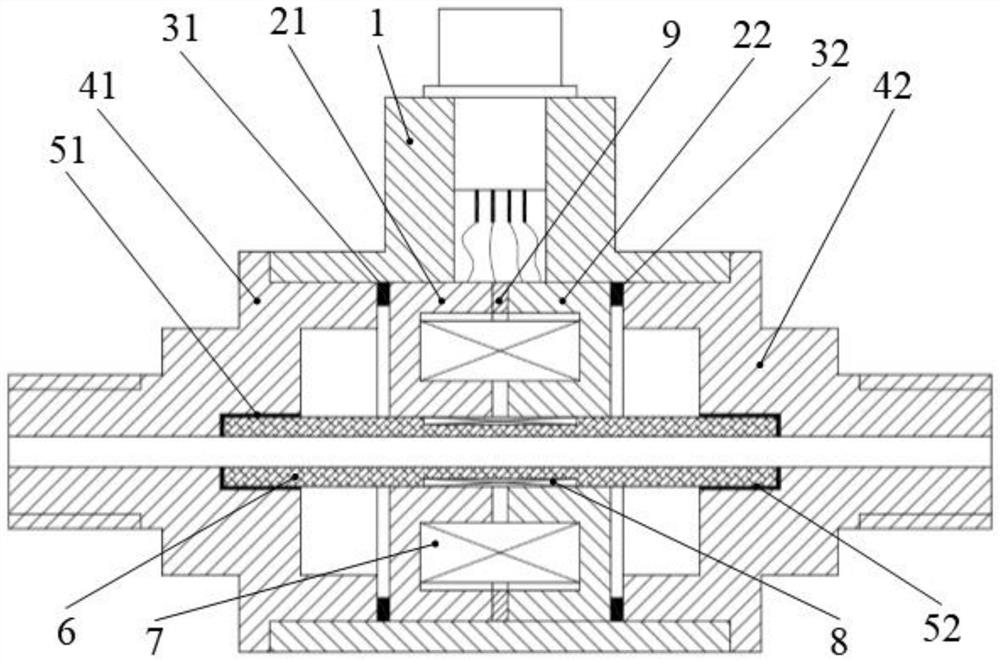

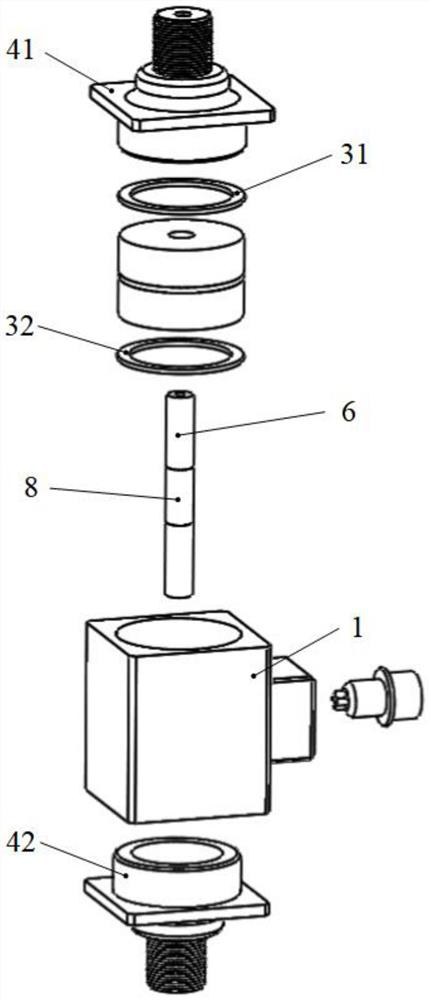

[0026] This embodiment further describes the above sensors.

[0027] Further, a first sealing rubber ring 51 and a second sealing rubber ring 52 are respectively provided at the joints of the first pipe joint 41 , the second pipe joint 42 and the oil pipe 6 .

[0028] Further, a first rubber gasket 31 and a second rubber gasket 32 are provided at the joints between the first pipe joint 41 and the second pipe joint 42 and the first pot-shaped magnetic pole 21 and the second pot-shaped magnetic pole 22 respectively.

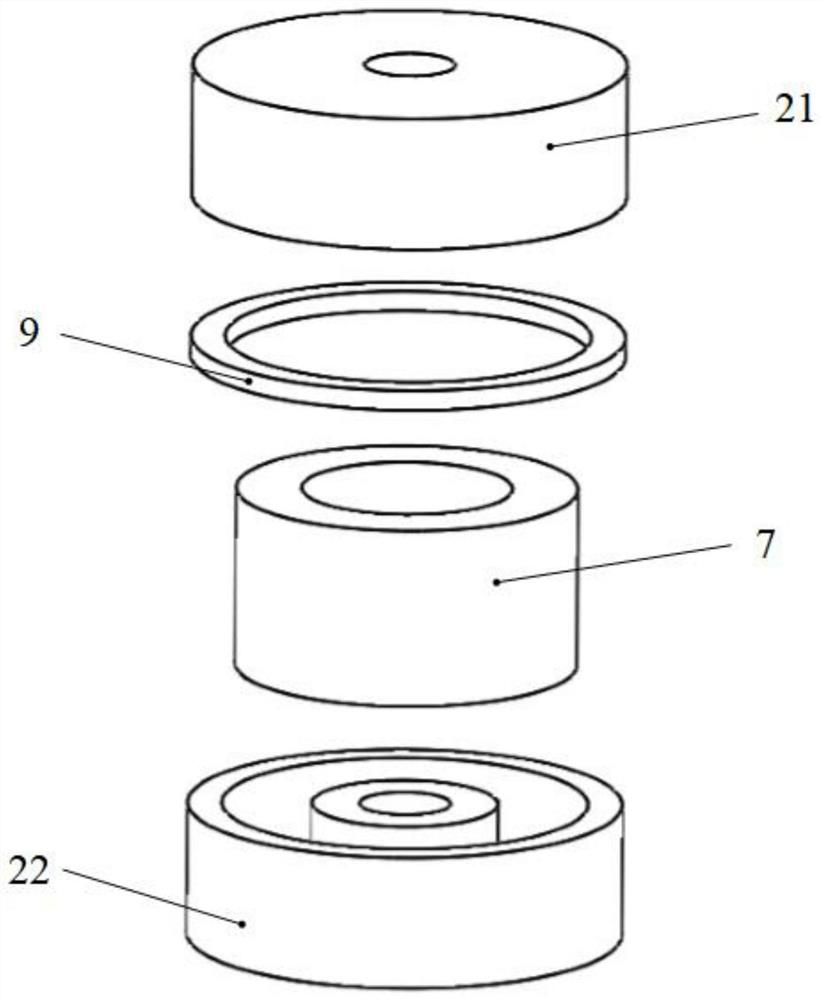

[0029] As in 3, the first pot-shaped magnetic pole 21 and the second pot-shaped magnetic pole 22 are circular groove structures, and the center position is a through hole. The circular groove structures of the first can-shaped magnetic pole 21 and the second can-shaped magnetic pole 22 are arranged symmetrically and facing each other.

[0030] The material of the first can-shaped magnetic pole 21 and the second can-shaped magnetic pole 22 is ferrite, and there i...

Embodiment 2

[0033] This embodiment provides a detection method of a metal particle detection sensor based on a high-frequency high-gradient magnetic field, including the metal particle detection sensor based on a high-frequency high-gradient magnetic field described in Embodiment 1, specifically including the following steps:

[0034] S1. The internal excitation coil 7 of the metal abrasive particle detection sensor passes high-frequency alternating current in the range of 10kHz-5MHz as excitation;

[0035] S2. When metal abrasive grains inside the oil pipe pass through the high-frequency and high-gradient magnetic field, the metal abrasive grain detection sensor can reflect the characteristics of the abrasive grains through changes in the induced voltage of the detection coil 8 .

[0036] When the metal abrasive particles pass through the sensor, the abrasive particles will affect the change of the magnetic flux, and then affect the change of the induced voltage. The winding direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com