Telescopic conveying mechanism of pipeline burying device for water conservancy project

A water conservancy project and transmission mechanism technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., can solve problems such as reduced work efficiency, potential safety hazards, easy shaking, etc., and achieve stable lubrication and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

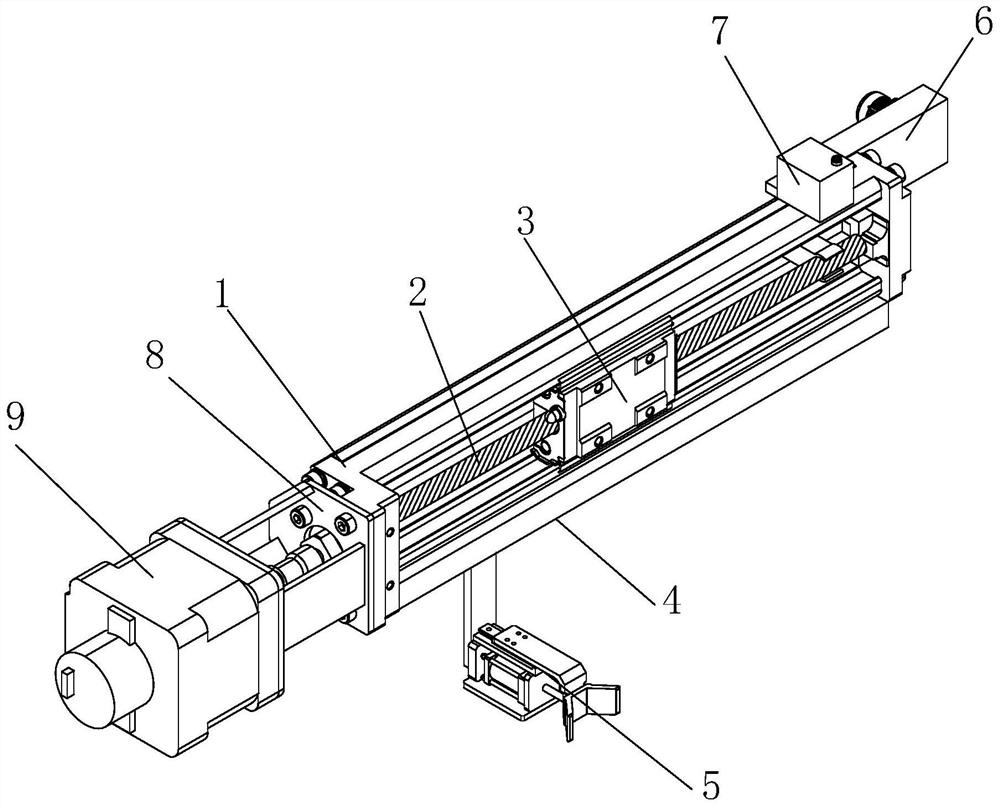

[0032] see figure 1 , the present invention provides a telescopic transmission mechanism of a pipeline embedding device for water conservancy projects through improvement, including a fixing part 1, a screw rod 2 is arranged in the middle of the fixing part 1, and the outer diameter surface of the screw rod 2 is connected with the slider 3, And the upper and lower ends of the back of the slider 3 are slidably connected to the inner side of the fixing part 1, the bottom of the fixing part 1 is equipped with a bottom plate 4, the left side of the fixing part 1 is fixed with the mounting frame 8, and the left side of the mounting frame 8 is provided with a first motor 9, The output shaft on the right side of the first motor 9 is connected to the left side of the screw rod 2 through a coupling, a supporting device 5 is provided at the bottom of the bottom plate 4, a pushing device 6 is installed at the right end of the back of the fixing member 1, and an oil outlet is installed at ...

Embodiment 2

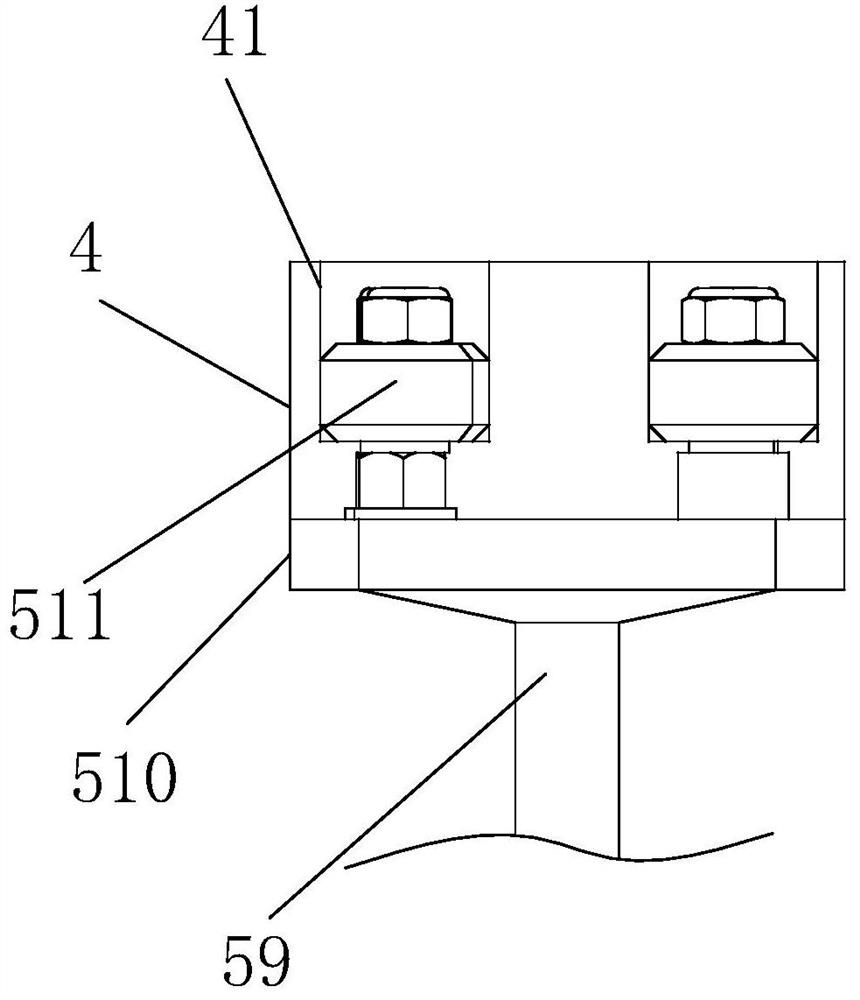

[0040] The present invention provides a telescopic transmission mechanism of a pipeline embedding device for water conservancy projects through improvement. There are four guide wheels 511, and the four guide wheels 511 are distributed at the front and rear ends of the chute 41 to facilitate stable sliding. Good fluency; the connecting port 642 is connected with a sealing ring, which is convenient to provide a sealing effect during the oil filling process to prevent leakage; the inner side of the oil filling port 72 has an internal thread, which is convenient for connection with the external sealing cover. When in use, it is effective Improve sealing effect.

[0041] The present invention provides a telescopic transmission mechanism of a pipeline embedding device for water conservancy engineering through improvement, and its working principle is as follows;

[0042] First, when the equipment needs to be used, the telescopic transmission mechanism is first installed on the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com