Method and device for evaluating urea crystallization risk based on steady-state working condition

A steady-state working condition and crystallization technology, which is applied to the electronic control of noise reduction devices, exhaust devices, and exhaust treatment devices, etc., can solve problems such as increased fuel consumption of the vehicle, high urea crystallization, and decreased conversion efficiency of post-treatment NOx. achieve high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

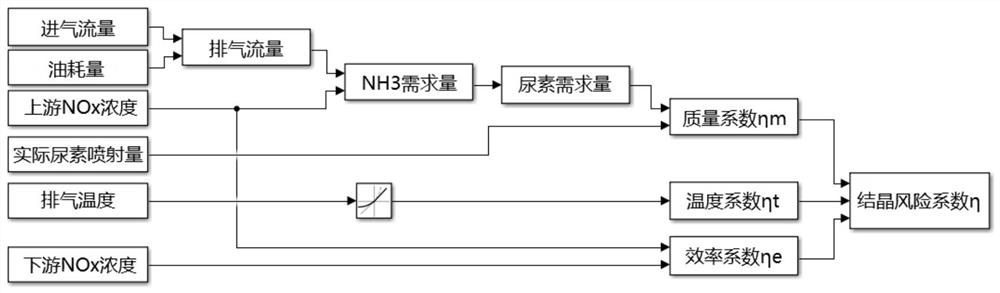

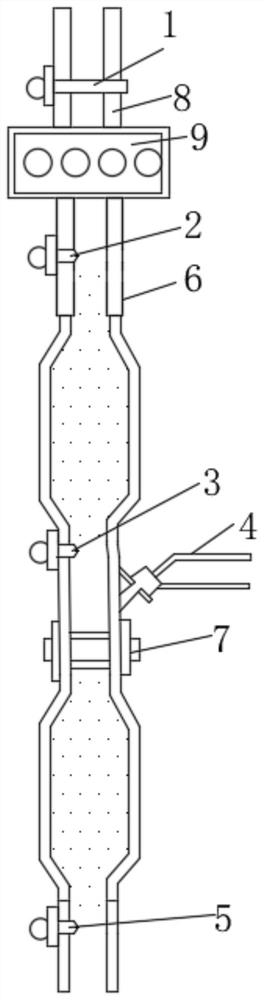

[0017] see Figure 1~2 , in an embodiment of the present invention, a method for evaluating the risk of urea crystallization based on steady-state working conditions is characterized in that: the urea crystallization risk coefficient η is evaluated by three coefficients, including quality coefficient ηm, temperature coefficient ηt and efficiency coefficient ηe, through Comparing the demand value of urea injection quantity with the actual urea injection quantity, determine the quality risk coefficient ηm from the perspective of evaluating the urea injection quantity; determine the temperature risk coefficient ηt from the perspective of temperature according to the detailed mechanism of urea decomposition; calculate by comparing the NOx concentration before and after SCR For the actual NOx conversion efficiency, the efficiency coefficient ηe is determined from the perspective of SCR conversion efficiency.

[0018] The mass coefficient ηm calculation method is based on the intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com