Thermodynamic system capable of achieving one-furnace-two-machine ultra-low load operation and switching method of one-furnace-two-machine ultra-low load operation

A technology of load operation and thermal system, applied in the direction of heating system, heating mode, mechanical equipment, etc., can solve the problems of complex layout and deep peak-shaving ability of units to be further explored, so as to enhance flexibility, improve production and operation efficiency, The effect of reducing the idle rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

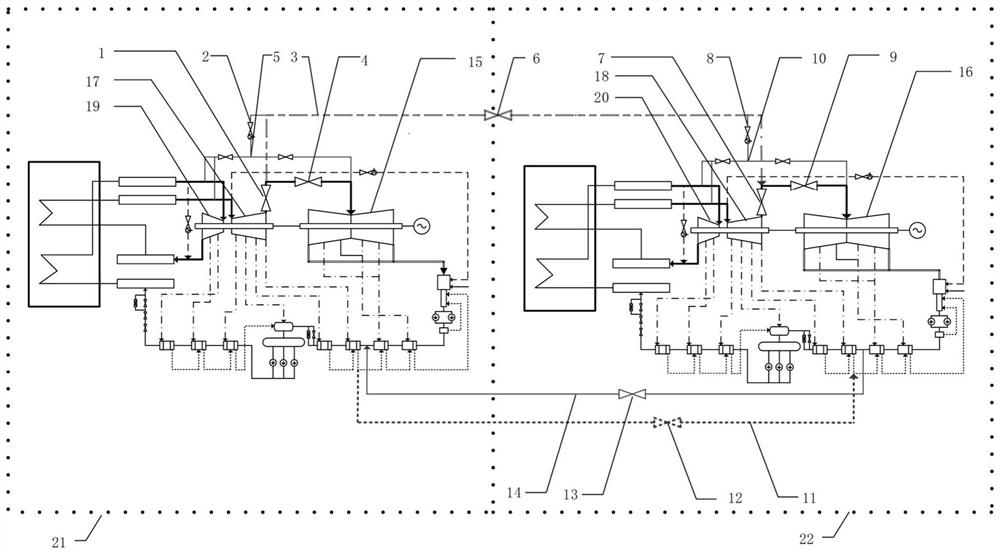

[0034]The present invention provides a thermal system with one furnace and two machines for ultra-low load operation, which includes two unitary units with the same capacity, equipment type and thermal system. The first unit unit 21 includes the first medium-pressure cylinder exhaust valve 1, the first temperature and pressure reducing valve 2, the first medium-pressure cylinder exhaust regulating valve 4, the first cylinder cooling steam pipeline 5, the first low-pressure Cylinder 15, the first medium pressure cylinder 17 and the first high pressure cylinder 19, the second unit system unit 22 includes the second medium pressure cylinder exhaust valve 7, the second temperature and pressure reducing valve 8, the second medium pressure cylinder exhaust valve Valve 9, the second cylinder cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com