Drilling operation efficiency evaluation system and method based on data feature recognition

A technology of data characteristics and evaluation system, applied in the field of drilling, can solve the problems of unseen promotion and use, waste of human resources, increase of labor costs, etc., to simplify the drilling orientation process, save labor costs, and prevent fraud risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. Embodiment of explosion-proof measuring probe of explosion-proof fixed assembly:

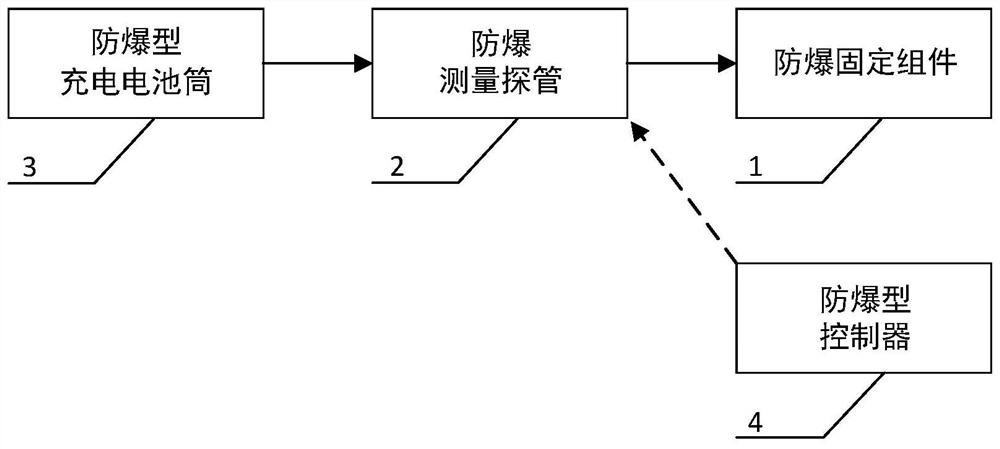

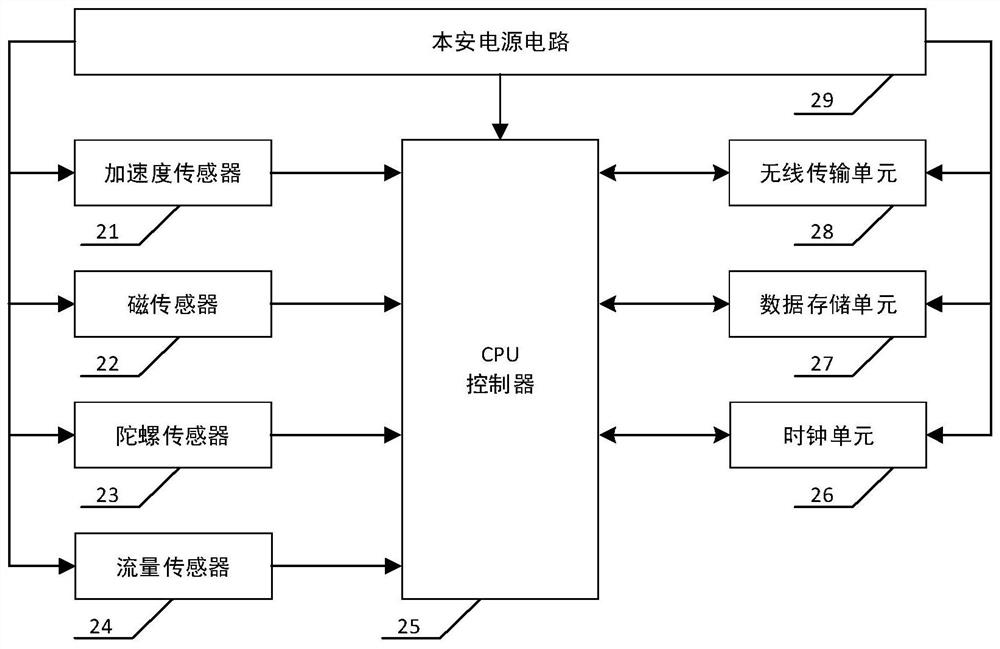

[0034] see figure 1 , the system in the present invention is composed of explosion-proof fixed assembly 1, explosion-proof measuring probe 2, explosion-proof rechargeable battery cartridge 3, and explosion-proof controller 4, all of which adopt explosion-proof design and can be applied in the explosive gas environment in underground coal mines.

[0035] Before drilling, select the matching fixing component 1 according to the specification and size of the drilling tool, assemble the explosion-proof measuring probe 2, the explosion-proof rechargeable battery cartridge 3 and the explosion-proof fixing component 1, and fix them in the drilling tool; Hole speed and drilling rig speed, set the appropriate delay time, sampling i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com