Unconventional natural gas well horizontal staged methane multi-stage pulse blasting fracturing enhanced extraction method

A technology of unconventional natural gas and explosive fracturing, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc., and can solve the problems of easy pollution of fracturing fluid, poor economic benefits, and low single well production, and achieve Reduce the risk of reservoir spontaneous combustion, the method is simple, and the effect of improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

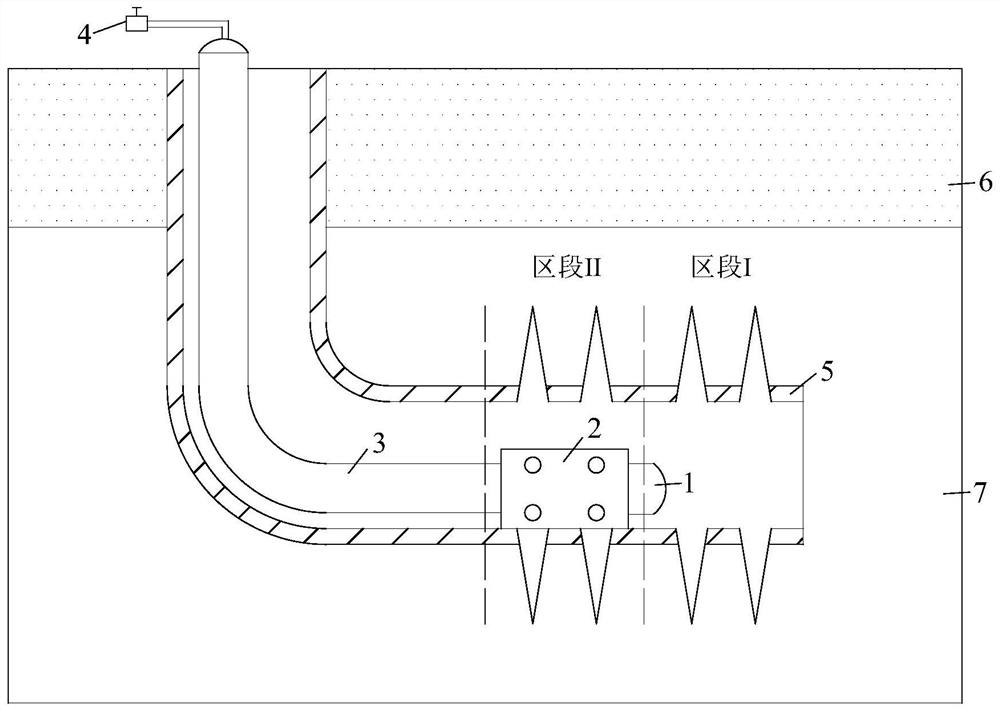

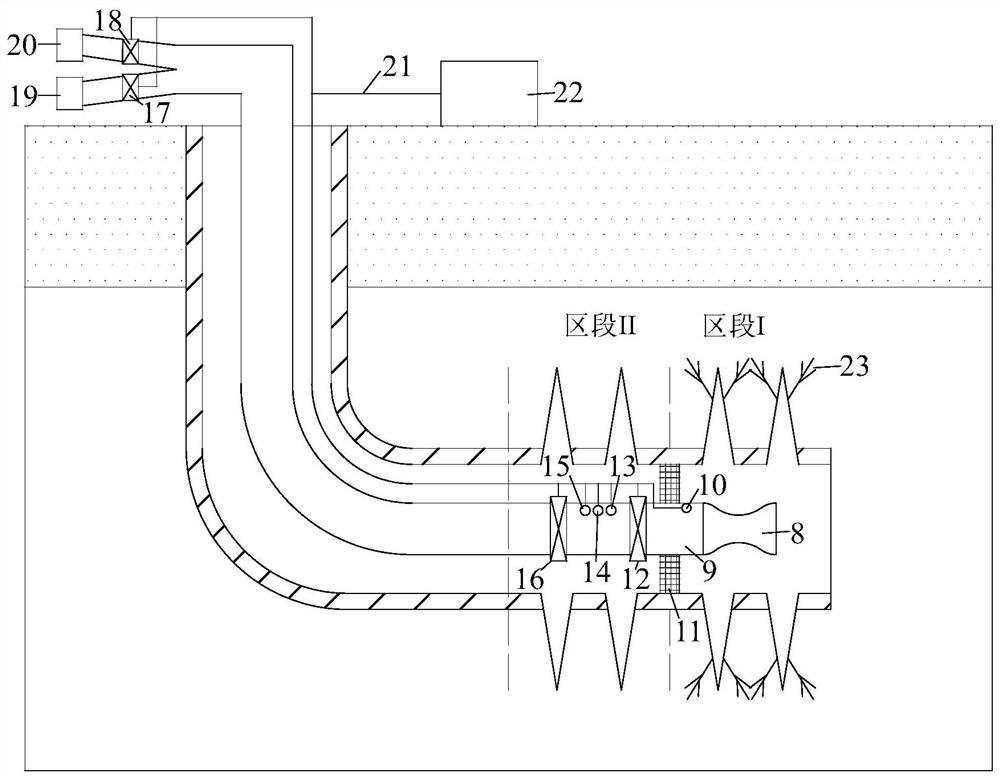

[0028] In the horizontal segmented methane multi-stage pulse explosion fracturing enhanced drainage method for unconventional natural gas wells of the present invention, the intervals from the bottom of the horizontal well to the joint of the vertical well are sequentially divided into section I, section II ... section N; Energy perforation system, methane multi-stage pulse explosion fracturing system and control console for enhanced drainage of multi-stage methane pulse explosion fracturing. Oxygen is injected into the section and pre-mixed with methane to form a certain concentration of mixed gas; methane is detonated to perform first-stage pulse explosion fracturing, causing reservoirs around the fracture tank; at the same time, high temperature promotes desorption of methane in the reservoir; when the monitored temperature and carbon monoxide conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com