Concrete socket capable of facilitating cushioning and fixing of building support frame

A support frame and concrete technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of no auxiliary anti-skid structure, no auxiliary limit, no insertion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

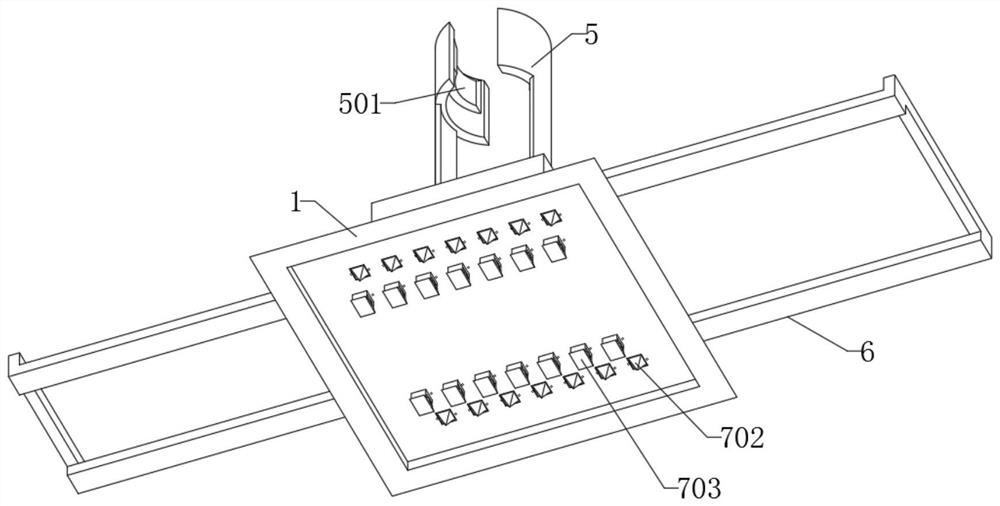

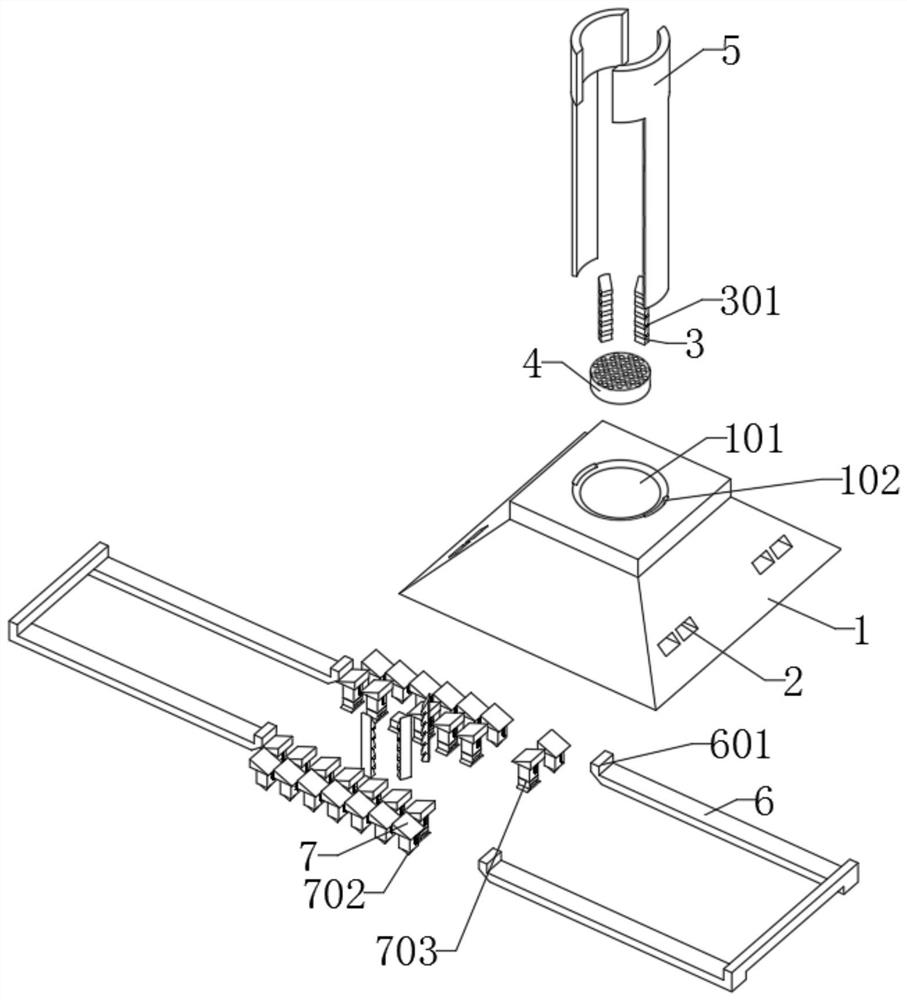

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a concrete socket that can facilitate the cushioning and fixing of the building support frame, including a main body 1, a stress groove 2, a block 3, a buffer member 4, a side plate 5, a control rod 6 and a force block 7; the main body 1 is the middle Protruding rectangular structure, and the main body 1 is the socket body; the block 3 is installed inside the socket 101, and the blocks 3 are arranged in a ring; the buffer 4 and the buffer rod 401 are made of rubber, and the bottom of the buffer 4 It is connected with the inner bottom of the socket 101; the side plate 5 is installed on both sides of the top of the main body 1, and the bottom of the side plate 5 is inserted and installed inside the side hole 102; the inner end of the control rod 6 is inserted and installed in the stress groove 2, and the limit head 601 of the control rod 6 is embedded in the limit groove 201;

[0036] Stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com