Super high-rise core tube joint bar retaining device and system and joint bar pre-embedding construction method

A core tube and super high-rise technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of poor construction effect and large loss of inserted ribs, so as to facilitate demoulding and disassembly operations, improve construction efficiency, and facilitate The effect of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

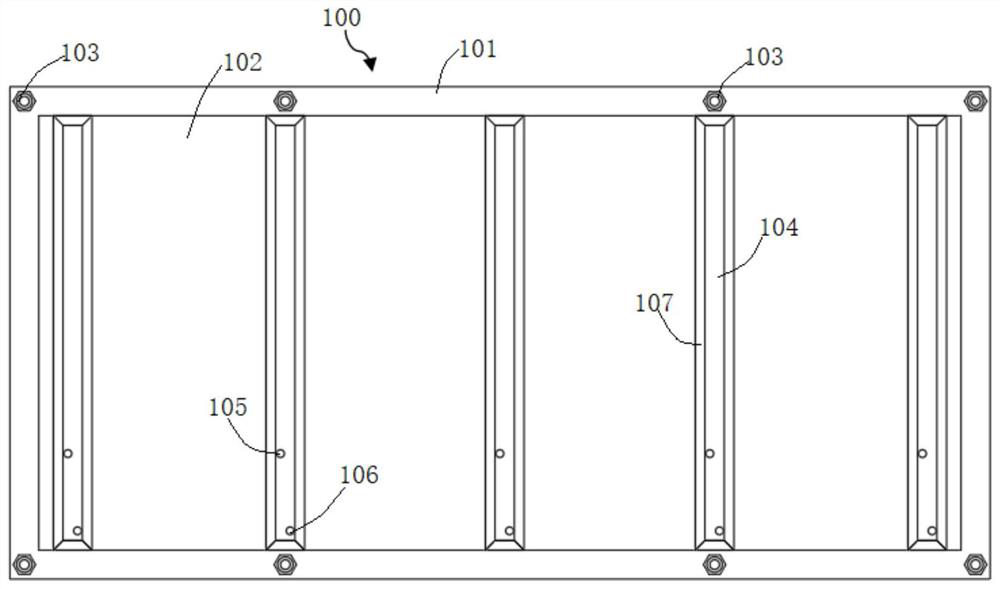

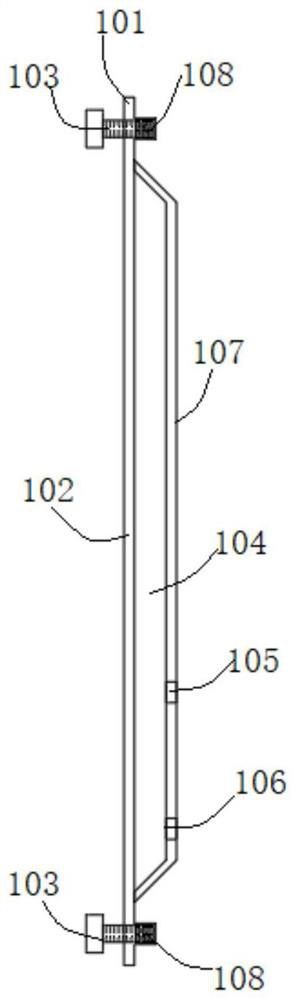

[0038] Such as figure 1 and figure 2 As shown, the indwelling device for super high-rise core tube inserting ribs in this embodiment, the indwelling device 100 includes a wing plate 101, a web 102 and a rib groove plate 107, the wing plate 101 forms a peripheral frame, and multiple sets of webs 102 are evenly spaced and parallel It is arranged inside the frame of the wing plate 101, and a grooved plate 107 is arranged between two adjacent groups of webs 102. The grooved plate 107 extends and protrudes toward the side of the web 102, and there is an opening in the grooved plate 107. The rib slot 104 and the upper bottom of the protruding bottom wall of the rib slot plate 107 are provided with an upper rib hole 105 and a lower rib hole 106 communicating with the rib slot 104 .

[0039] Specifically, in this embodiment, the wing plate 101 is a frame made of strip steel plates, and the web 102 is made of rectangular steel plates. The thickness of the wing plate 101 and the web pla...

Embodiment 2

[0044] The super-high-rise core tube inserting bar retention device of this embodiment is basically the same as that of Embodiment 1. Furthermore, in this embodiment, the end of the wire cap 108 away from the direction of the wing plate 101 is a closed structure, and the end of the wire cap 108 close to the direction of the wing plate 101 is a closed structure. There is no gap connection between one end and the wing plate 101 . More specifically, the screw cap 108 should be configured as a cylindrical or regular polygonal sleeve structure, and the sleeve is provided with a threaded hole matching with the bolt 103, and the sleeve can be integrated with the wing plate 101 to ensure a gap-free connection. The end of the sleeve away from the direction of the wing plate 101 is a closed structure to ensure that the pouring quality will not be affected during the pouring process and to facilitate subsequent demoulding and disassembly operations.

[0045] In this embodiment, the rib g...

Embodiment 3

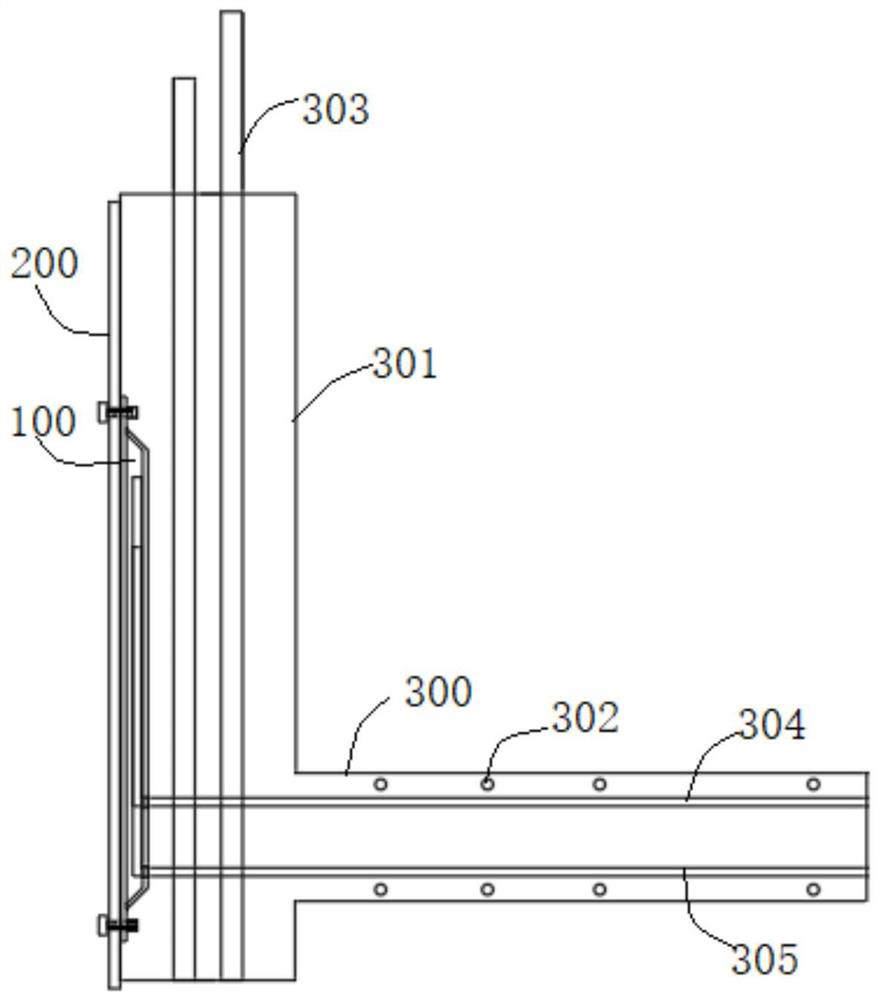

[0047] The super-high-rise core tube insertion bar indwelling system of this embodiment includes a template 200 and the indwelling device 100 in the above-mentioned embodiment, that is, the indwelling device 100 is provided with installation holes and thread caps 108, and the template 200 is correspondingly provided with installation holes and bolts. 103 cooperates with the silk cap 108 to securely connect the template 200 and the indwelling device 100. The side of the indwelling device 100 facing away from the template 200 is provided with an outwardly protruding groove plate 107, and there is a rib facing the template 200 in the rib groove plate 107. The rib insertion groove 104 of the opening, the outwardly protruding bottom wall of the rib groove plate 107 is provided with an upper rib hole 105 and a lower rib hole 106 communicating with the rib insertion groove 104, and the specific structure of the indwelling device 100 will not be repeated. Specific as image 3 Shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com