Large-span steel structure arch bridge and construction method

A construction method and steel structure technology, which is applied to arch bridges, bridges, bridge parts, etc., can solve the problems of lack of aesthetic feeling, large ups and downs of the abutment line, and easy quality defects caused by the stress on the abutment, so as to increase the overall stability , increase smoothness and beauty, optimize the effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

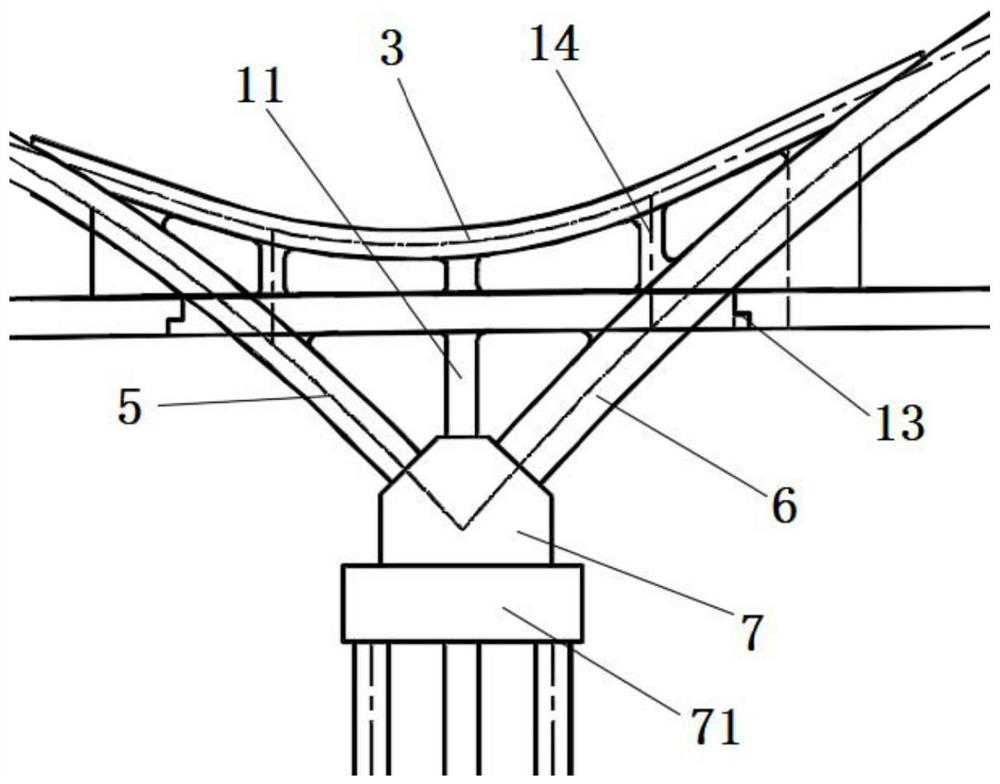

[0036] see Figure 1-3 , the present application provides a long-span steel structure arch bridge, comprising a bridge deck 12, a side arch rib 1, and a middle arch rib 2, and abutments 8 are arranged on both sides below the bridge deck 12, and the middle arch rib 2 , the side arch rib 1 is located on both sides of the bridge deck 12, the two ends of the middle arch rib 2 are connected with the side arch rib 1, and the other end of the side arch rib 1 is connected with the abutment 8, The connection between the middle arch rib 2 and the side arch rib 1 is provided with a middle triangle structure, and the connection between the side arch rib 1 and the abutment 8 is provided with a side triangle structure.

[0037] In this embodiment, the middle triangular area structure includes the middle upper limb arch 3 connected with the arch foot 6 of the side arch rib 1 and the arch foot of the middle arch rib 2, and the middle upper limb arch 3 and the arch foot 6 are connected to each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com