Intelligent and automatic capping device of cosmetic filling bottles on assembly line

A technology for cosmetics and filling bottles, which is applied to the field of intelligent automatic capping devices for cosmetic filling bottles in assembly lines, can solve the problems of high cost, low work efficiency, and large labor for manual capping, and achieves low cost, high service life, and reduced The effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

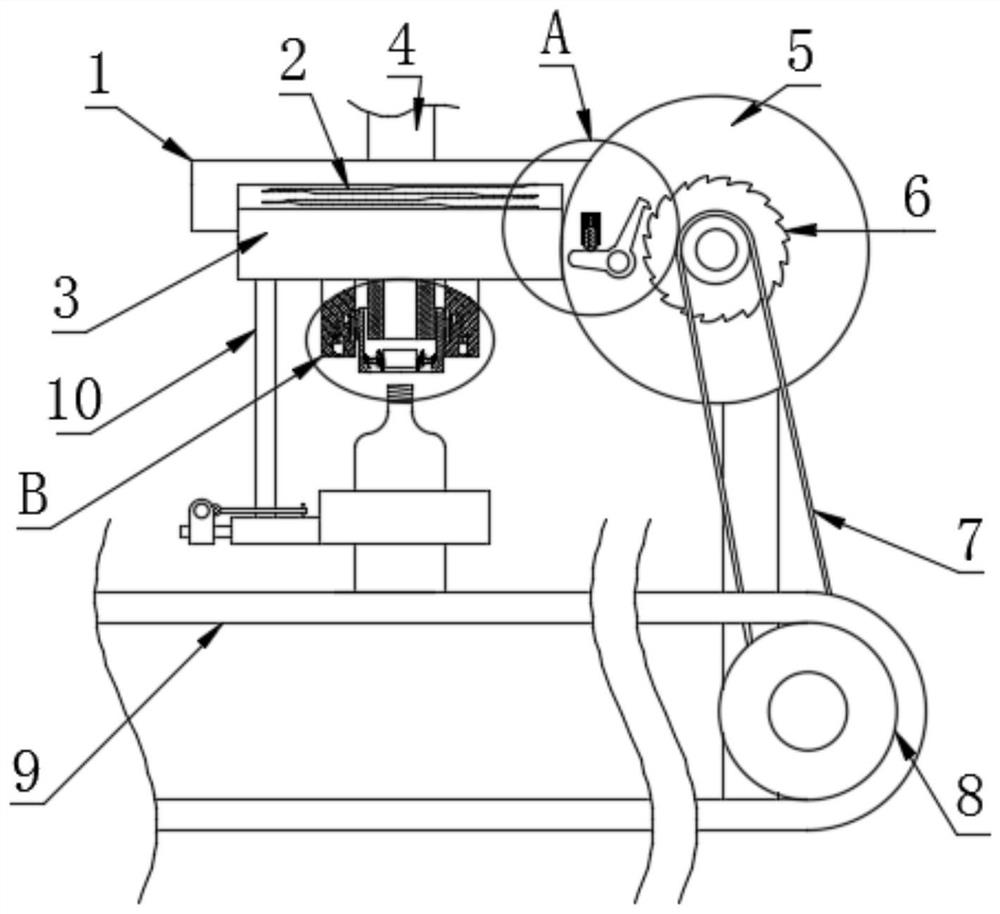

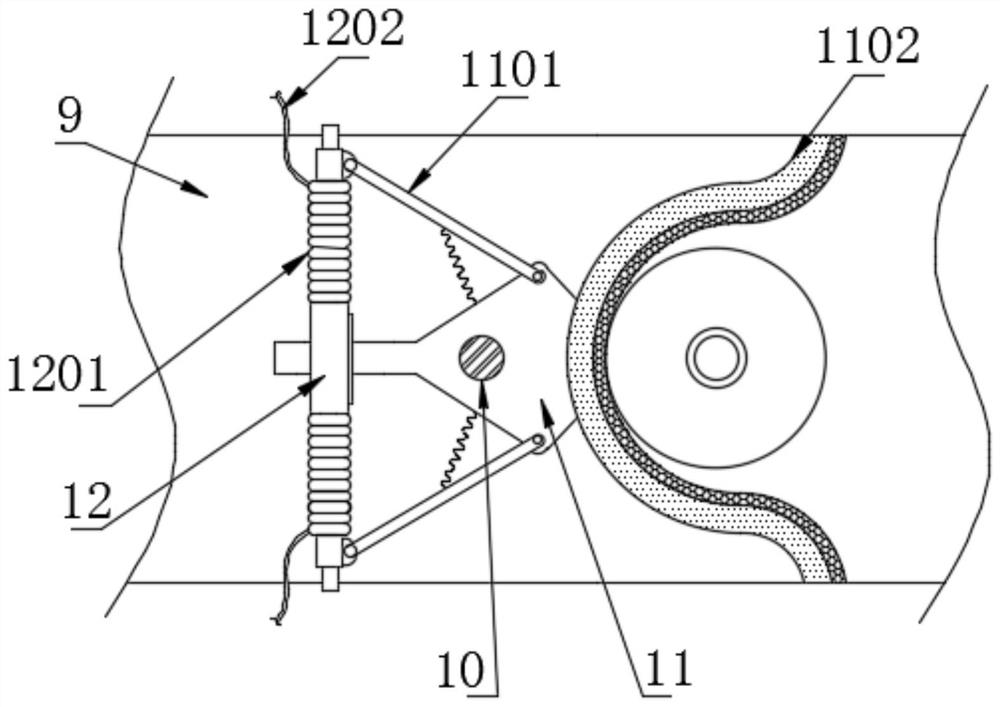

[0025] as attached figure 1 to attach Figure 5 As shown: the present invention provides an intelligent automatic capping device for cosmetic filling bottles on an assembly line. The specific usage and function of this embodiment:

[0026] In the present invention, an assembly line cosmetic filling bottle intelligent automatic capping device includes a fixed frame 1, the lower part of the fixed frame 1 is fixedly connected with a torsion spring 2, and the lower end of the torsion spring 2 is fixedly connected with a rotating disk 3, and the rotating disk 3 A cavity 301 is opened on the inner lower side of the rotating disk 3 , and an L-shaped rod 302 is slidably connected to the inside of the rotating disk 3 and in the cavity 301 , and a piston corresponding to the cavity 301 is arranged on the lower part of the L-shaped rod 302 . The inner end of the L-shaped rod 302 is provided with a screw rod 303 in the rotating disk 3, the middle part of the fixed mount 1 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com