Non-woven cotton cloth rolling, tensioning and cutting device for beauty makeup

A cutting device and cotton cloth technology, which is applied in the direction of winding strips, transportation and packaging, textiles and papermaking, etc., can solve the problems of increasing production costs, single winder, and affecting production efficiency, and achieve small footprint and easy operation. The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The "above" and "below" mentioned in this embodiment are consistent with the directions above and below the drawings themselves, which are only for the convenience of description and clarification, and are not used to limit the scope of the present invention, and the changes or adjustments of their relative relationships , without substantively changing the technical content, it should also be regarded as the scope of the present invention that can be implemented.

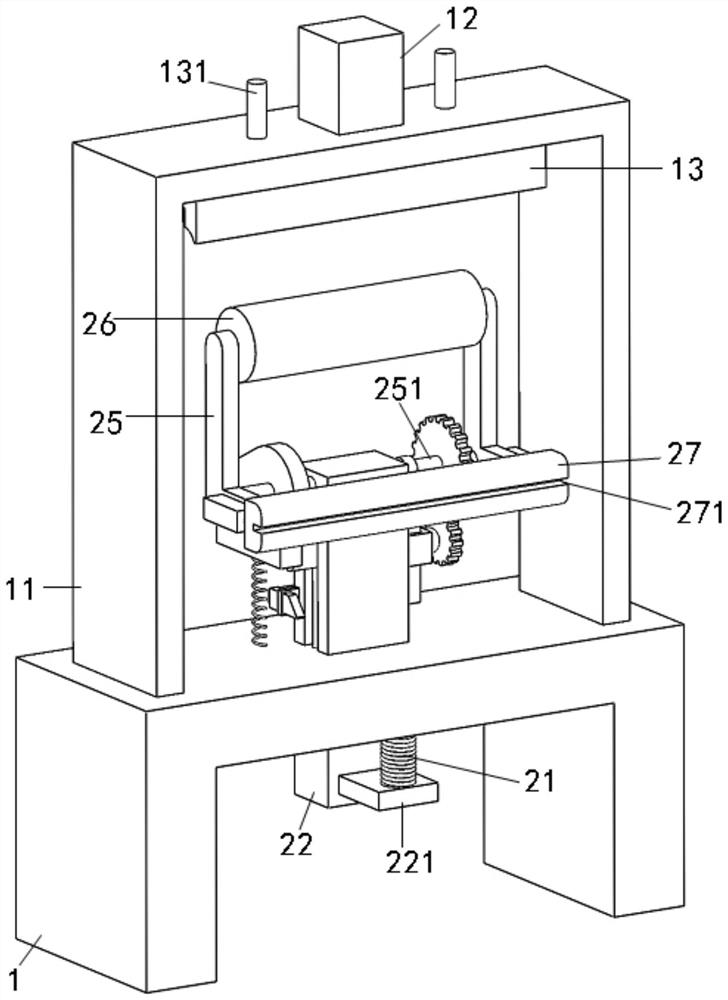

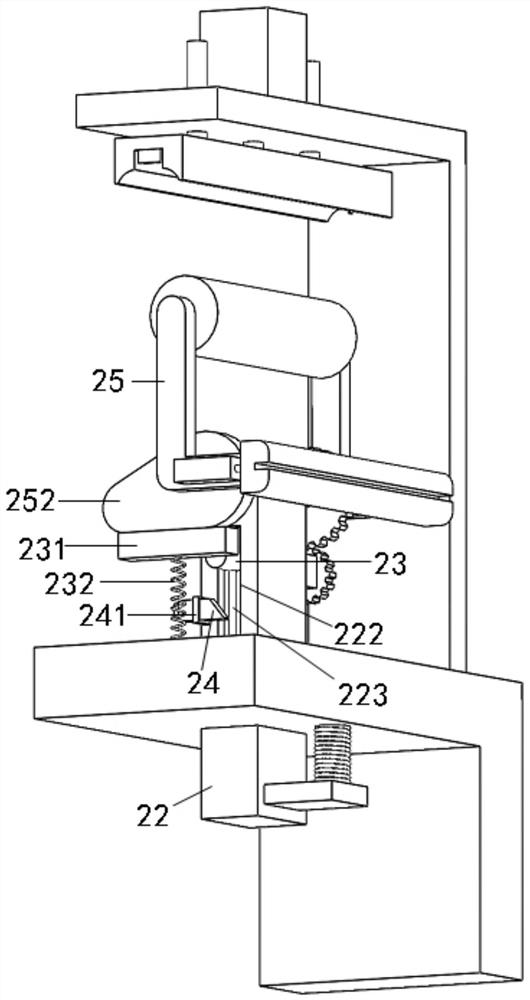

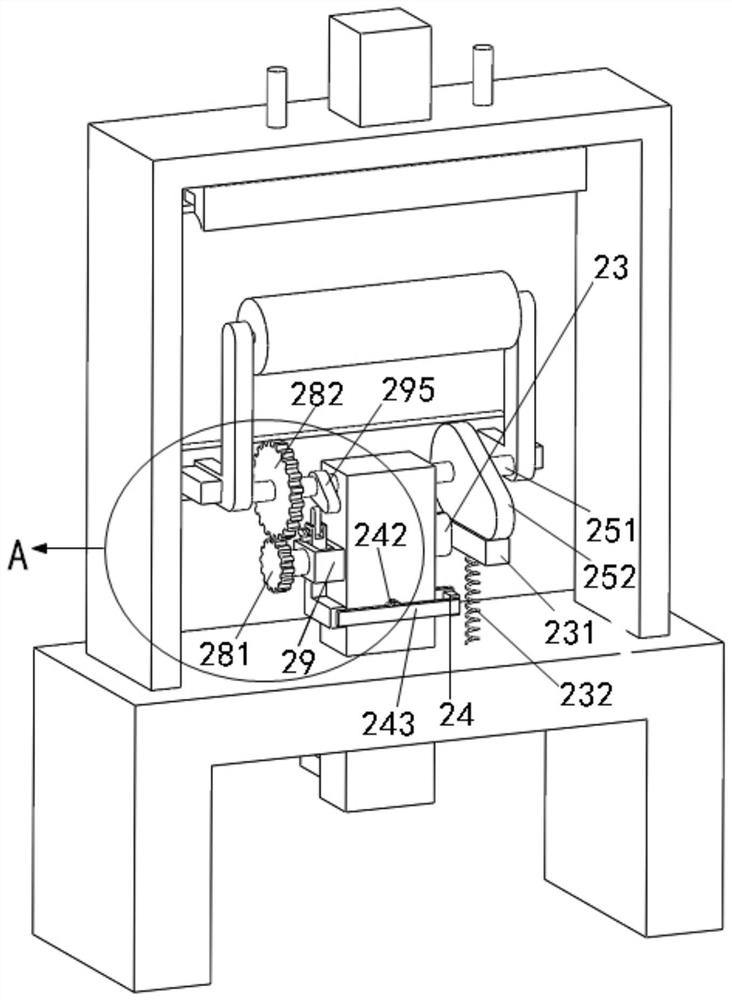

[0023] Depend on Figure 1 to Figure 8 As shown, a non-woven cotton cloth winding tensioning cutting device for cosmetics includes a bottom frame 1 and support frames 11 fixed on both sides of the top surface of the top plate of the bottom frame 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com