Broken hole blocking method for degradable plastic bag blow molding device

A blow molding device, plastic bag technology, applied in packaging, bag making operations, transportation and packaging, etc., can solve problems affecting production efficiency, film breakage, holes, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

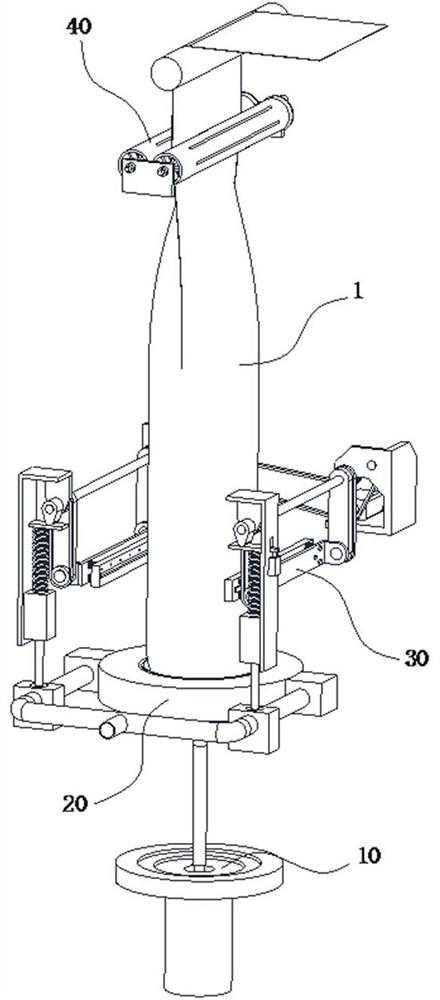

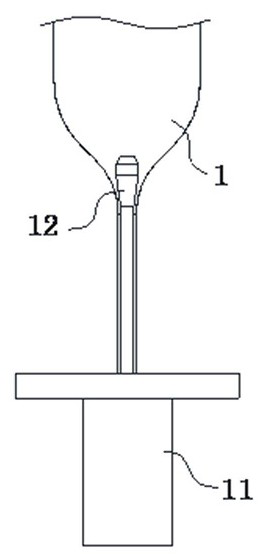

[0030] Such as figure 1 Shown, a kind of degradable plastic bag blow molding device comprises blow molding head 10, and the annular air curtain device 20 that is arranged in order from bottom to top above blow molding head 10, sealing device 30 and anti-fracture mechanism 40; figure 2 As shown, the blow molding die head 10 includes a heating extrusion device 11 with an annular extrusion port and a blowing pipe 12 that is located at the center of the annular extrusion port and protrudes upwards. Under the action of air pressure, it expands into a cylindrical plastic film 1 , and an air pressure sensor 652 is provided on the air blowing pipe 12 .

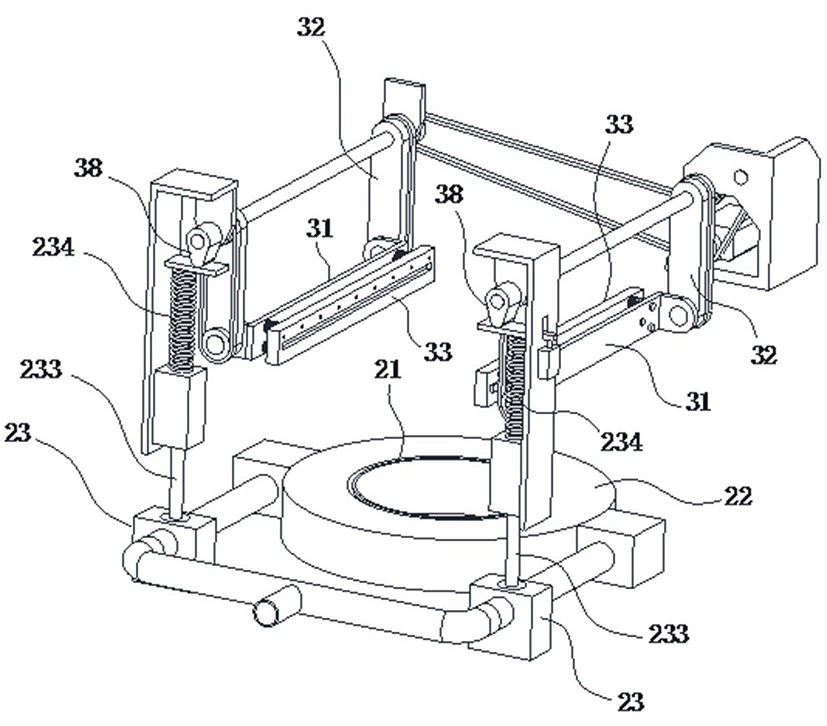

[0031] Such as image 3 , 4 , 5, 7, and 8, the sealing device 30 includes two splints 33 positioned at both sides of the tubular plastic film 1, the two splints 33 are mutually opened and closed, and the two splints 33 are movable up and down, and the two splints 33 are respectively There is a first hot-sealing strip 34; it also i...

Embodiment 2

[0045] A method for repairing holes in the continuous blow molding process of degradable plastic bags, comprising the steps of:

[0046] Step 1: Using the pressure sensor 652 to monitor the air pressure in the tubular plastic film 1 discharged from the blow molding die 10 described in Embodiment 1 in real time;

[0047] Step 2: When the pressure sensor 652 detects that there is a momentary loss of pressure in the cylindrical plastic film 1, it means that the cylindrical plastic film 1 has a hole. Blowing around the annular air curtain keeps the cylindrical plastic film 1 in an upright state and prevents it from swinging, while utilizing the sealing device 30 described in embodiment 1 to cut off the hole area from the cylindrical plastic film 1 below;

[0048] Step 3: heat seal the reinforcement pattern in the hole area to prevent the tubular plastic film 1 from being torn at the hole.

[0049] In the step 3, the anti-fracture mechanism 40 in the first embodiment is used to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com