Sand shooting device used for manufacturing process and capable of improving sand core quality

A technology of manufacturing process and quality, which is applied in the field of sand shooting device to improve the manufacturing process of sand core quality, which can solve the problems of not being able to produce small sand cores and reduce equipment investment, so as to reduce false sand blowing, reduce production costs, and reduce modification costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

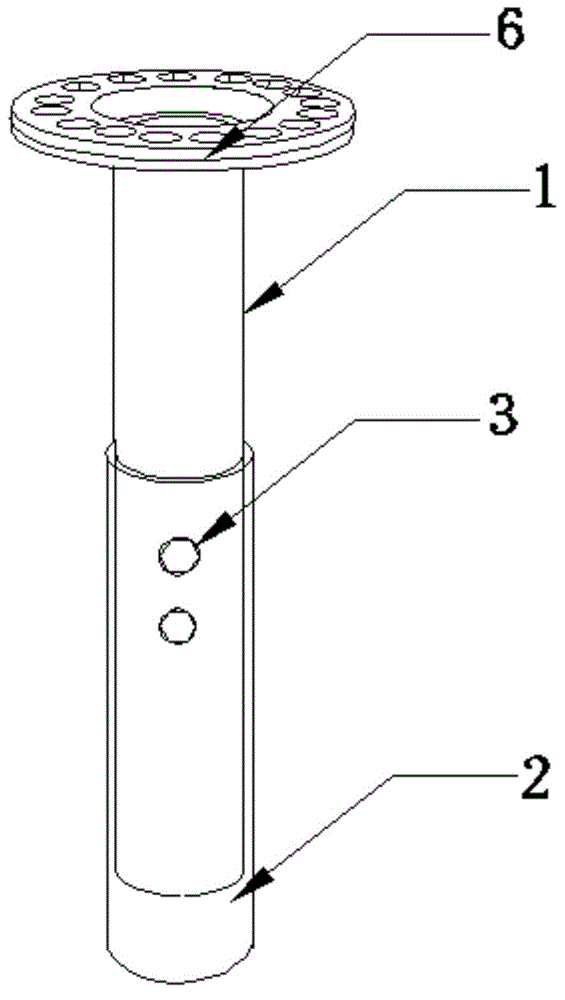

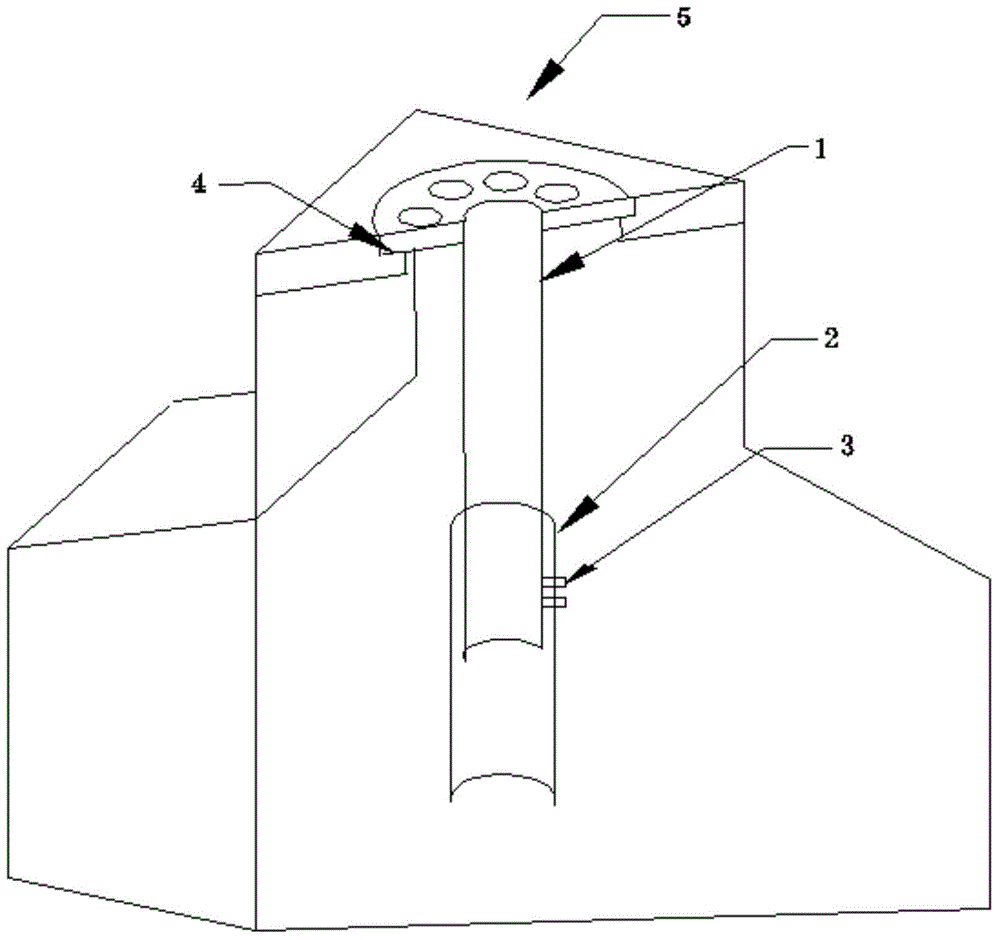

[0021] The embodiment of the present invention combines figure 1 , figure 2 described as follows:

[0022] A sand shooting device for improving the manufacturing process of sand core quality, comprising a T-shaped round pipe sand delivery pipe 1, a sand injection volume adjustment pipe 2, fixing bolts 3 and a sealing ring 6, the T-shaped round pipe sand delivery pipe 1 is directly installed in the manufacturing The core machine moves the sand-shooting head and the cavity opening 4, and the sand-shooting volume regulating pipe 2 is installed on the T-shaped round pipe sand-feeding pipe 1. In addition, the upper end of the T-shaped round pipe sand-feeding pipe 1 has a plurality of exhaust holes.

[0023] The T-shaped round pipe sand delivery pipe 1 is installed in the cavity opening 4 of the mobile injection head of the core making machine, and can be directly attached to the sand adding mechanism and the sand shooting mechanism of the core making machine.

[0024] The shot s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com