A production method capable of automatically shaping memory alloy wire

A technology of memory alloy wire and production method, which is applied in the direction of furnace type, conveying filamentous materials, furnace, etc., can solve the problems of cumbersome operation, low efficiency, and high labor cost, and achieve cumbersome operation, improved applicability, and reduced labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

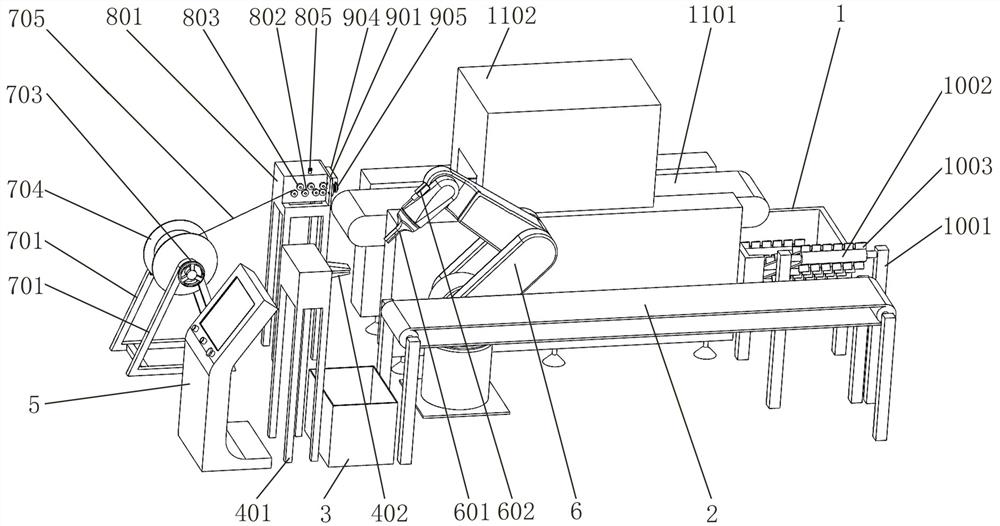

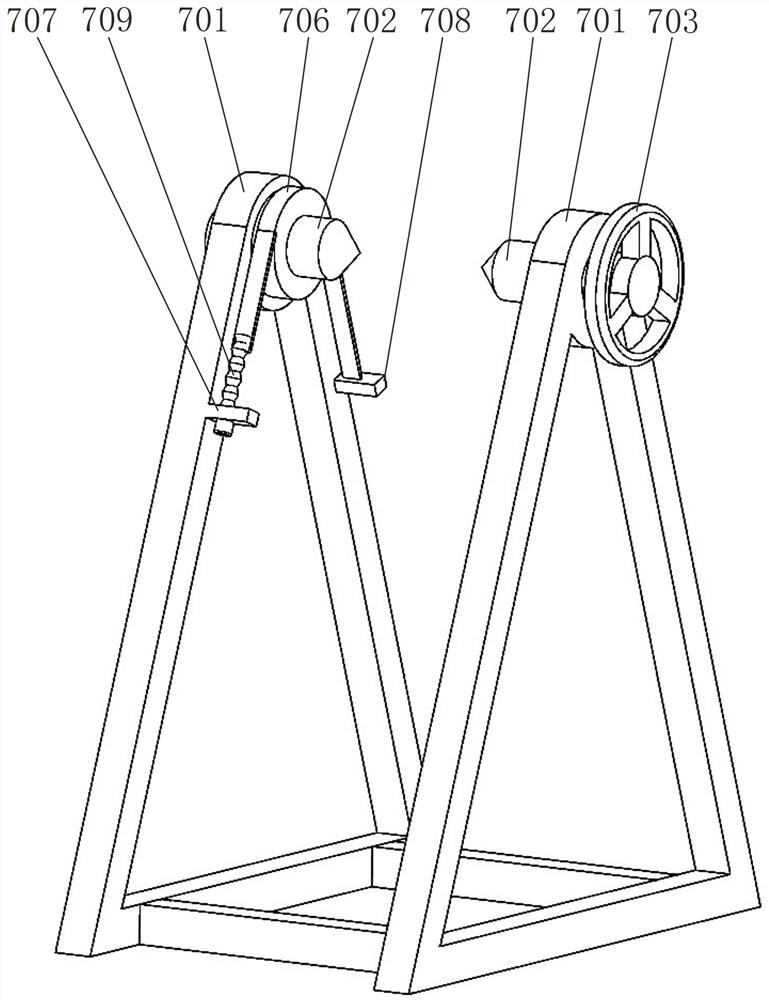

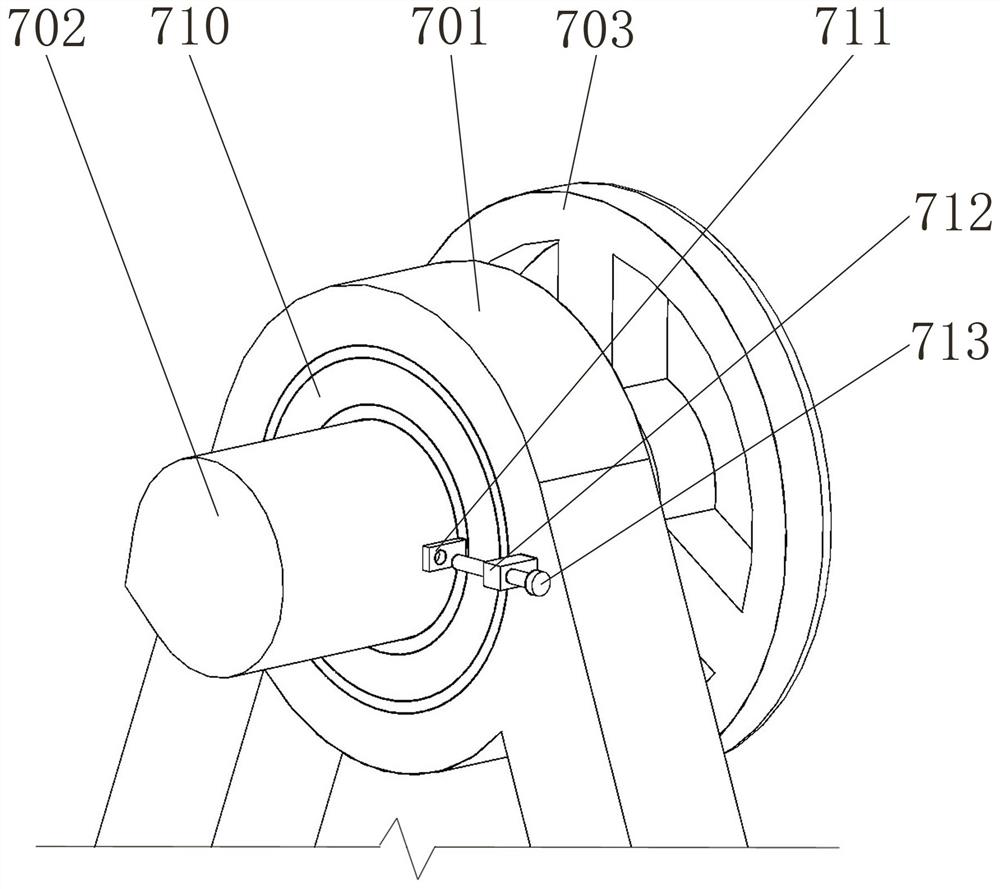

[0056] A method for producing memory alloy wires that can be automatically shaped. The method is used for producing memory alloy orthodontic wires. The wire diameter of the memory alloy orthodontic wires is 0.46 mm. Figure 4 The sizing die 12 shown, the sizing die 12 is made of stainless steel, and its inner diameter is 0.47mm, and the shape matches the shape of the memory alloy orthodontic wire; the diameter of the guide hole 903 is 0.465mm. The guide column 902 , and the guide post 902 is installed on the fixing plate 901 through the locking nut 909 and the flange 906; the production batch of the memory alloy orthodontic wire is 5000; the production method of the present invention adopts the following steps Implemented:

[0057] S1: Selection of production procedures: According to the specifications and models of memory alloy products to be produced, select the production procedures on PLC5 that can meet the setting parameters of memory alloy orthodontic wires;

[0058] S2...

Embodiment 2

[0068] A method for producing memory alloy wires that can be automatically shaped. The method is used for producing memory alloy orthodontic wires. The wire diameter of the memory alloy orthodontic wires is 0.51 mm. The selected setting die 12 is made of stainless steel tubes. , and its inner diameter is 0.52mm, and the shape matches the shape of the memory alloy orthodontic wire; the guide hole 903 is selected as a guide column 902 with a diameter of 0.515mm, and the guide column 902 is connected to the flange 906 through the locking nut 909 Installed on the fixing plate 901; the production batch of the memory alloy orthodontic wire is 3000; the production method of the present invention is realized by the following steps:

[0069] S1: Selection of production procedures: According to the specifications and models of memory alloy products to be produced, select the production procedures on PLC5 that can meet the setting parameters of memory alloy orthodontic wires;

[0070] S2...

Embodiment 3

[0080] A method for producing memory alloy wires that can be automatically shaped. The method is used for producing memory alloy orthodontic wires. The wire diameter of the memory alloy orthodontic wires is 0.31 mm. The selected setting die 12 is made of stainless steel tubes. , and its inner diameter is 0.32mm, and the shape matches the shape of the memory alloy orthodontic wire; the guide hole 903 is selected with a diameter of 0.315mm for the guide column 902, and the guide column 902 is connected to the flange 906 through the locking nut 909. Installed on the fixing plate 901; the production batch of the memory alloy orthodontic wire is 6000; the production method of the present invention is realized by the following steps:

[0081]S1: Selection of production procedures: According to the specifications and models of memory alloy products to be produced, select the production procedures on PLC5 that can meet the setting parameters of memory alloy orthodontic wires;

[0082]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com