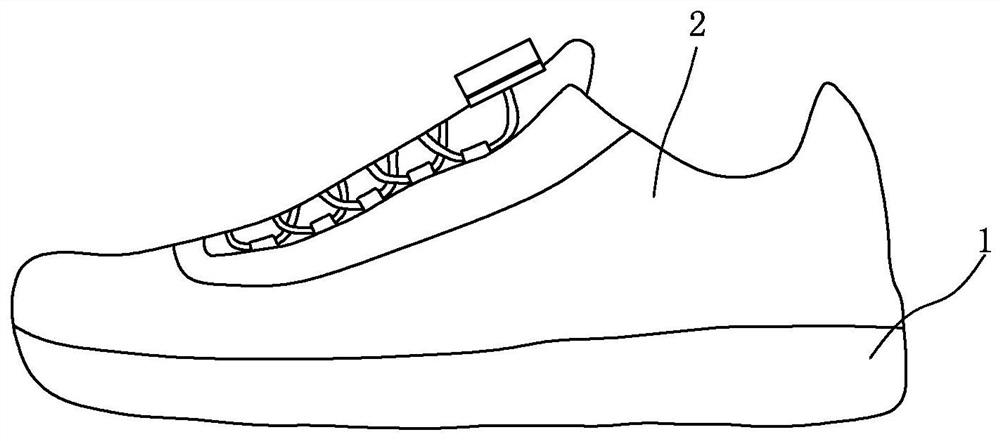

A preparation process for flat foot orthopedic shoes in growth period

A preparation process and technology for flat feet, which is applied in the field of preparation of flat feet corrective shoes in the growing period, can solve problems such as single function, achieve the effects of protecting flat feet, relieving foot fatigue, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

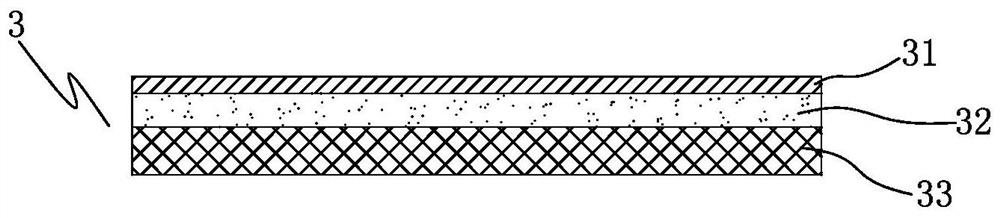

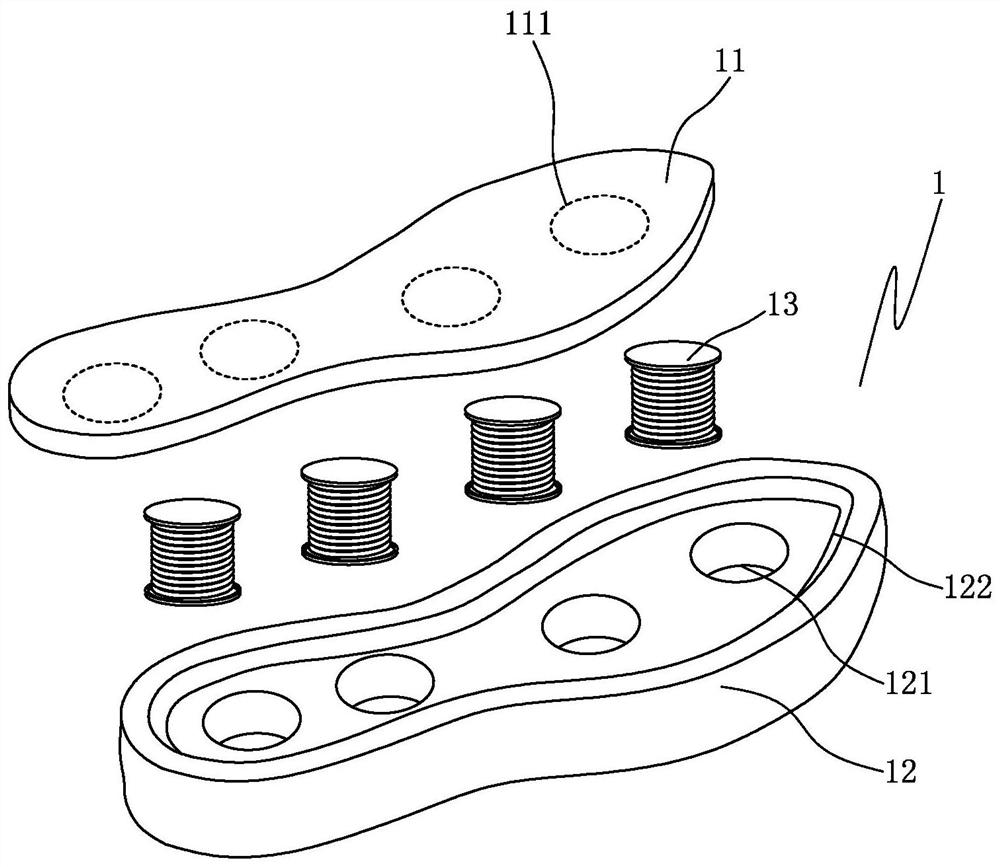

[0043] The insole body 33 is composed of the following raw materials by weight: 20 parts of ethylene-vinyl acetate copolymer, 15 parts of negative ion powder, 35 parts of modified copolymer, 2.5 parts of cyanoacrylate, 2 parts of antioxidant, 0.05 part of sodium hydrosulfite , 0.8 part of talcum powder, 0.5 part of stearic acid, and further, the modified copolymer is polymerized by corn starch, ethylene acrylic acid and ethyl acetate in a mass ratio of 1:2:5; antioxidant is composed of antioxidant BHT and antioxidant 2246 is composed of a mass ratio of 1:2; by limiting the composition of antioxidants, it can improve the performance of the insole body and prolong the service life of the insole body.

[0044] The viscose 32 is made up of the following raw materials by weight: 50 parts of butyl methacrylate, 2 parts of ethylene glycol, 8 parts of dioctyl adipate, 8 parts of polyvinyl formal, 8 parts of talcum powder, 5 parts of clam powder parts, 1 part of nano-porcelain powder, ...

Embodiment 2

[0046] The insole body 33 is composed of the following raw materials by weight: 25 parts of ethylene-vinyl acetate copolymer, 12 parts of negative ion powder, 25 parts of modified copolymer, 3.5 parts of cyanoacrylate, 1 part of antioxidant, 0.12 part of sodium hydrosulfite , 0.5 part of talcum powder, 0.8 part of stearic acid, and further, the modified copolymer is polymerized by corn starch, ethylene acrylic acid and ethyl acetate in a mass ratio of 1:2:5; antioxidant is composed of antioxidant BHT and antioxidant 2246 is composed of a mass ratio of 1:2; by limiting the composition of antioxidants, it can improve the performance of the insole body and prolong the service life of the insole body.

[0047] The viscose 32 is made up of the following raw materials by weight: 60 parts of butyl methacrylate, 6 parts of ethylene glycol, 15 parts of dioctyl adipate, 5 parts of polyvinyl formal, 12 parts of talcum powder, 3 parts of clam powder parts, 2 parts of nano-porcelain powder...

Embodiment 3

[0049] The insole body 33 is composed of the following raw materials by weight: 22 parts of ethylene-vinyl acetate copolymer, 13 parts of negative ion powder, 30 parts of modified copolymer, 3 parts of cyanoacrylate, 1.5 part of antioxidant, 0.08 part of sodium hydrosulfite , 0.65 part of talcum powder, 0.7 part of stearic acid, and further, the modified copolymer is polymerized by corn starch, ethylene acrylic acid, and ethyl acetate in a mass ratio of 1:2:5; antioxidant is composed of antioxidant BHT and antioxidant 2246 is composed of a mass ratio of 1:2; by limiting the composition of antioxidants, it can improve the performance of the insole body and prolong the service life of the insole body.

[0050] The viscose 32 is made up of the following raw materials by weight: 55 parts of butyl methacrylate, 4 parts of ethylene glycol, 12 parts of dioctyl adipate, 6 parts of polyvinyl formal, 10 parts of talcum powder, 4 parts of clam powder parts, 1.5 parts of nano-porcelain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com