Semi-automatic dried beancurd stick production line

A production line, semi-automatic technology, applied in food science, cheese substitutes, dairy products, etc., can solve the problems of not meeting the development needs of enterprises, the high cost of automatic equipment, and the inability to classify production well, and improve the freshness and taste. , the effect of simple structure and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

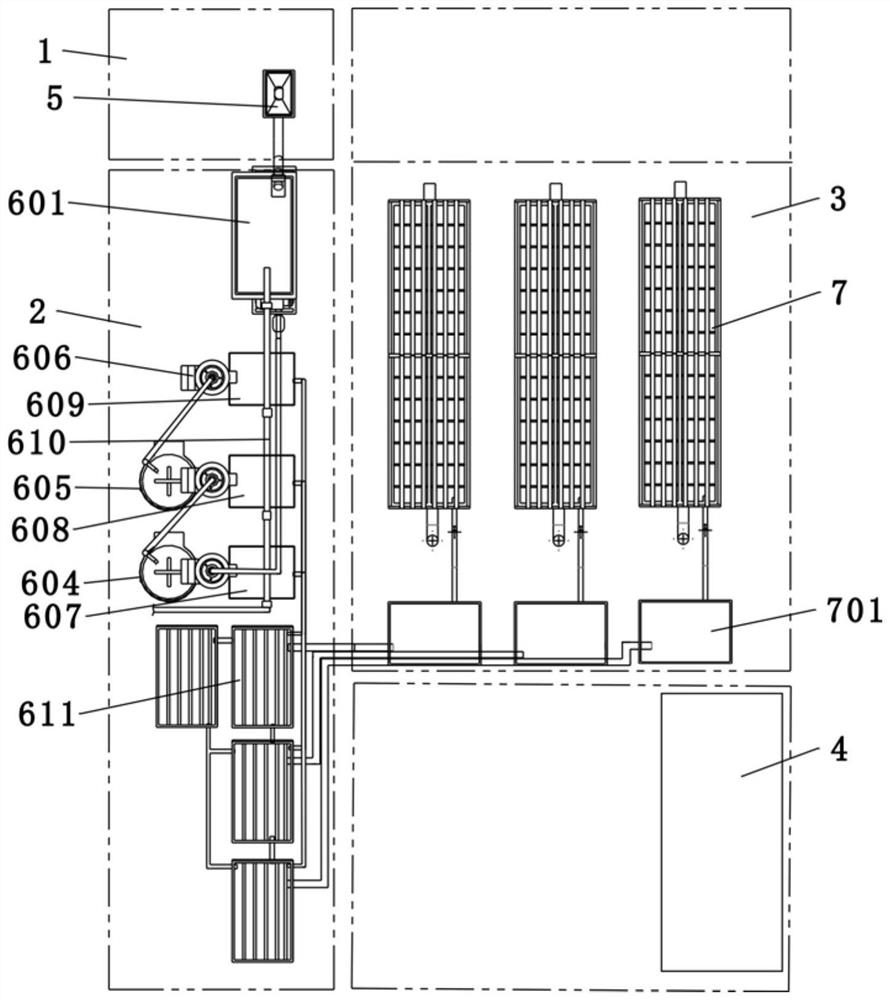

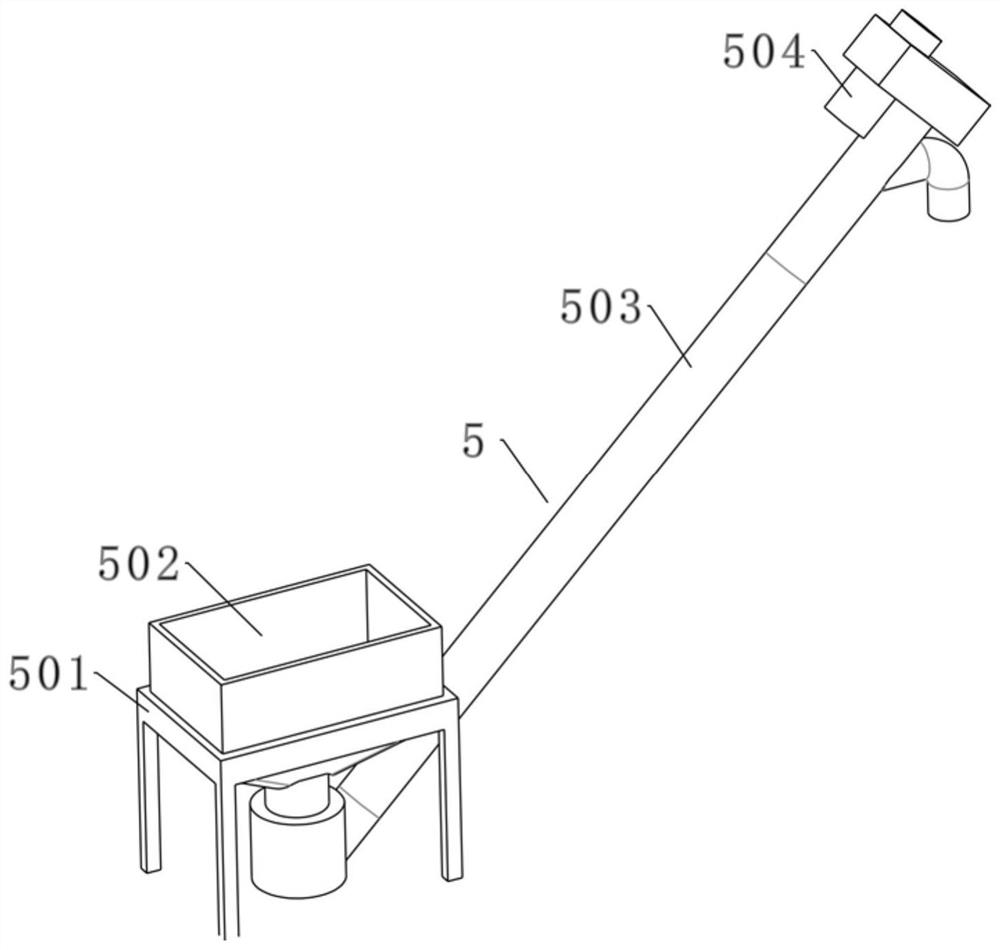

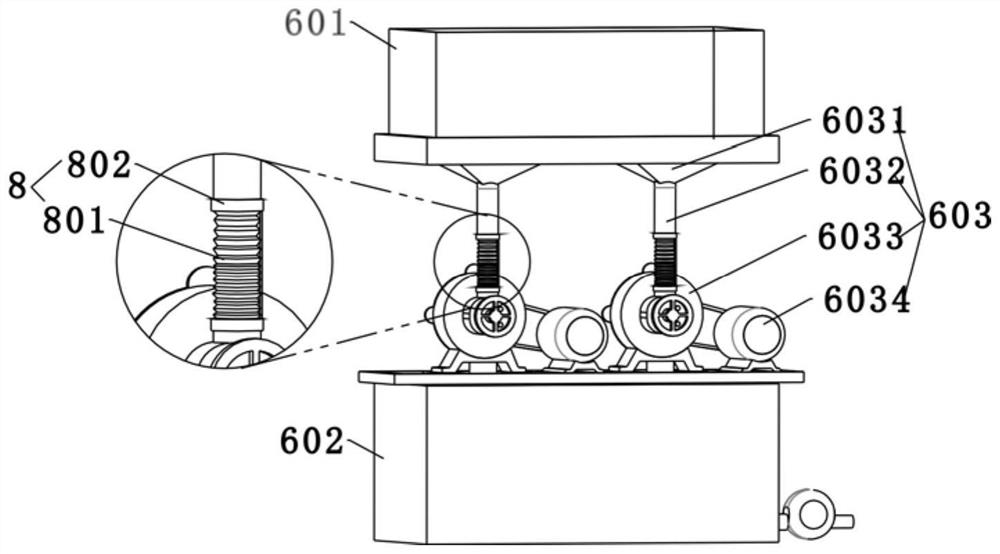

[0036] see Figure 1-Figure 6 Shown, a kind of typical embodiment of the present application provides a kind of semi-automatic bean curd stick production line, and it comprises material delivery area 1, pulp cooking area 2, bean curd stick molding area 3, drying area 4, is respectively arranged in material delivery area 1, The feeding device 5 of the boiling area 2, the bean curd stick forming area 3, the cooking device 6, the peeling device 7 and the heating system for the bean curd stick forming, the feeding device 5 transports the raw materials to the cooking device 6, and the cooking device 6. Grinding the raw materials to make soybean milk. The milk cooking device 6 transports the soybean milk to the peeling device 7. The soybean milk is cooled and crusted on the peeling device 7. Then the soybean skin is manually pulled out and dried in the air. The fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com