GaAs E/D process low-power-consumption phase inverter circuit

An inverter and low power consumption technology, applied in logic circuits, electrical components, pulse technology, etc., can solve the problems of increasing inverter power consumption, large power supply voltage deviation, and large quiescent current, so as to reduce layout area, The effect of simplifying the circuit structure and reducing static power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

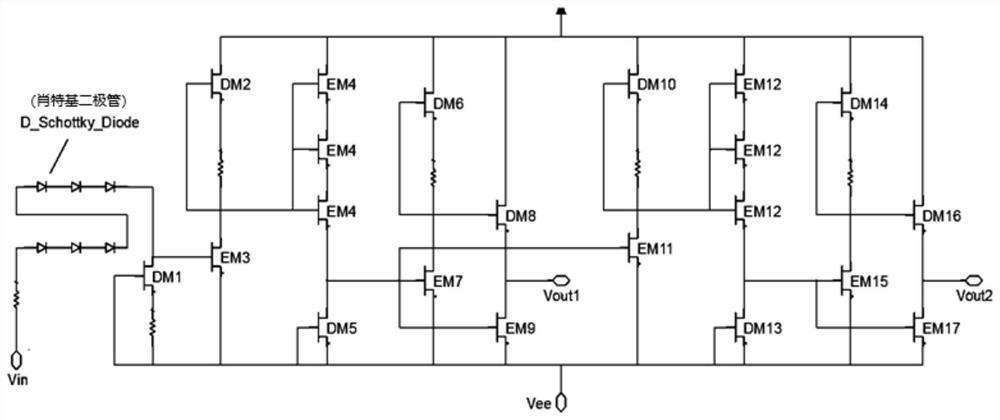

[0020] see Figure 1 to Figure 3 , the present invention provides a technical solution:

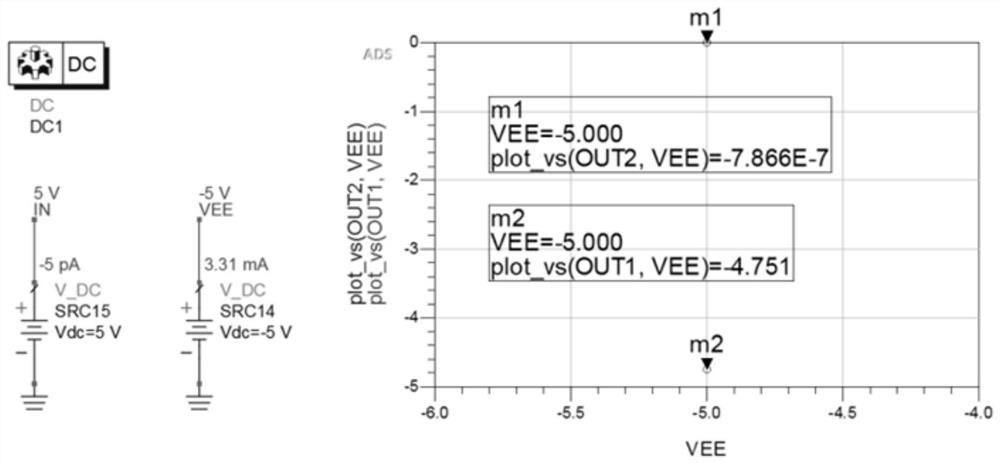

[0021] The invention proposes a new low power consumption inverter circuit. In the existing inverter, the drain of the potential shift output point D tube (DM1) is connected to the gate of the E tube (EM3), and the conduction of the E tube (EM4) is controlled by controlling the switch of the E tube (EM3) or off, the output can control the E tube (EM7 and EM9) to turn on or off the required high and low level -4 / -5V, and an output signal of 0V or -5V is obtained through the drain output of the E tube (EM9); the E tube ( After the gate of EM7), continue to connect two stages of inversion to get a complementary output signal -4.75V or 0V, where the gate and source of the D tubes (DM2, DM6, DM10, DM14) are connected as a constant current source.

[0022] Further, through the potential shift circuit, the TTL logic control level is converted into -4 / -5V high and low levels that can meet the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com