Hot-pressing preparation method and performance testing method for heterogeneous metal composite block material test

A technology of heterogeneous metals and testing methods, applied in the preparation of test samples, testing material strength by applying stable tension/compression, testing material strength by applying stable shear force, etc., can solve the problem that process parameters cannot be accurately controlled Controlling and affecting the performance of the composite interface, etc., to achieve the effect of short test period, rapid preparation, and guaranteed interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

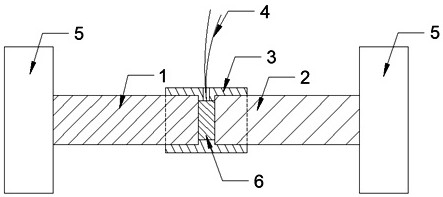

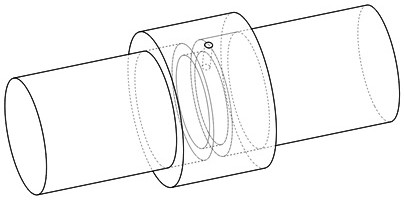

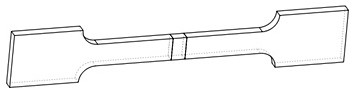

[0047] Such as figure 1 , 2 As shown, a method for preparing a heterogeneous metal composite bulk material by hot pressing for testing, comprising the following steps:

[0048] Step 1, surface treatment: sand and polish the surfaces of the metal A bar 6, the metal B sleeve 3 with a circular step in the middle, the metal B bar 1 and the metal B bar 2 of the same size and size with sandpaper, and then Wipe clean with alcohol after cleaning with acetone;

[0049] The metal B sleeve 3 is the same metal as the bars of the metal B bar one 1 and the metal B bar two 2 .

[0050] The size of the metal A bar 6 matches the size of the circular step in the middle of the metal B sleeve 3; the diameters of the metal B bar one 1 and metal B bar two 2 match the metal B sleeve The inner diameter of the cylinder 3 is matched.

[0051] Step 2, assemble the sample: place the metal A bar 6 on the circular step in the middle of the metal B sleeve 3, and then place the metal B bar 1 and the metal ...

Embodiment

[0070] In this embodiment, two materials, TA2 and low-carbon steel with a C content of 0.18%, are selected for hot pressing.

[0071] The specific operation steps are as follows:

[0072] Step 1, surface treatment: use two low-carbon steel bars with a size of φ15×45mm, a low-carbon steel sleeve with a size of φ20×25 mm and a wall thickness of 2.5mm, and a TA2 bar with a size of φ12×5mm. Sand paper to polish, then clean with acetone and wipe clean with alcohol.

[0073] Step 2, assemble the sample: Assemble the TA2 bar stock at the circular step in the middle of the low-carbon steel sleeve, then assemble two low-carbon steel bars on both sides of the sleeve respectively, and the end faces are close to the two ends of the TA2 bar stock ; And the thermocouple wire is welded on the side of the TA2 bar stock through the sleeve through hole whose diameter φ is 2mm on the sleeve.

[0074] Step 3, isolation and anti-sticking: apply high-temperature lubricant to the other two ends of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com