Particle inertial-capacitance damping device

A technology of damping devices and particles, which is applied in the direction of building types, buildings, building components, etc., can solve the problems of difficult vibration conditions of particle dampers, reduce the vibration conditions of damping particles, and do not have their own energy consumption capacity, so as to achieve maintenance costs Low cost, reduced vibration conditions, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

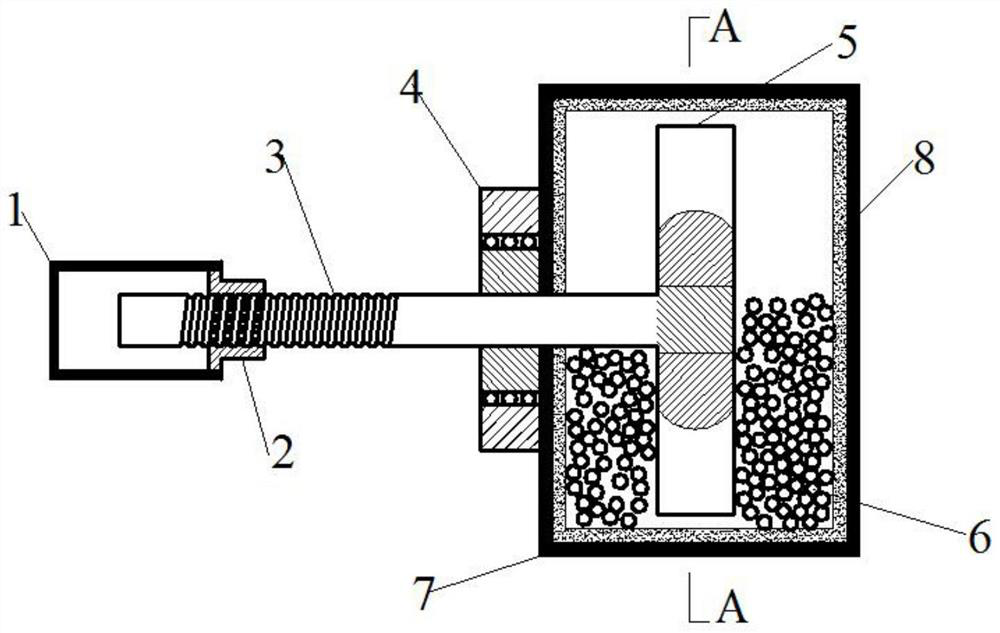

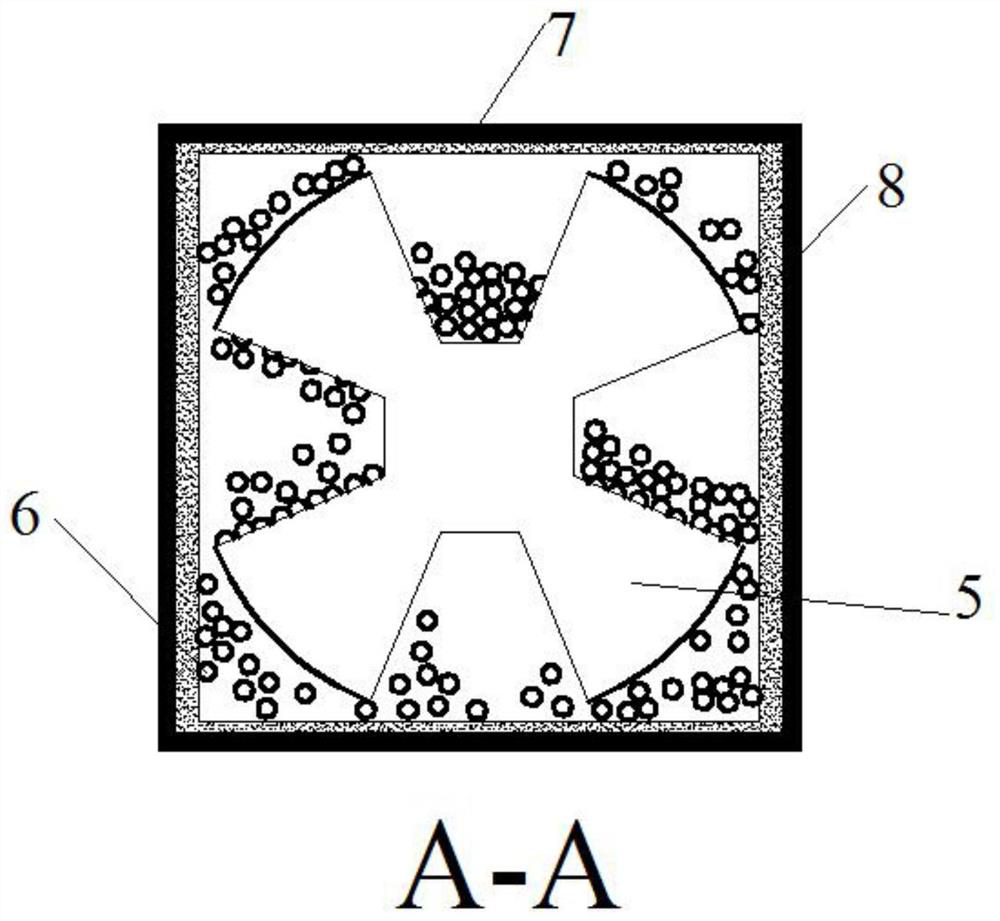

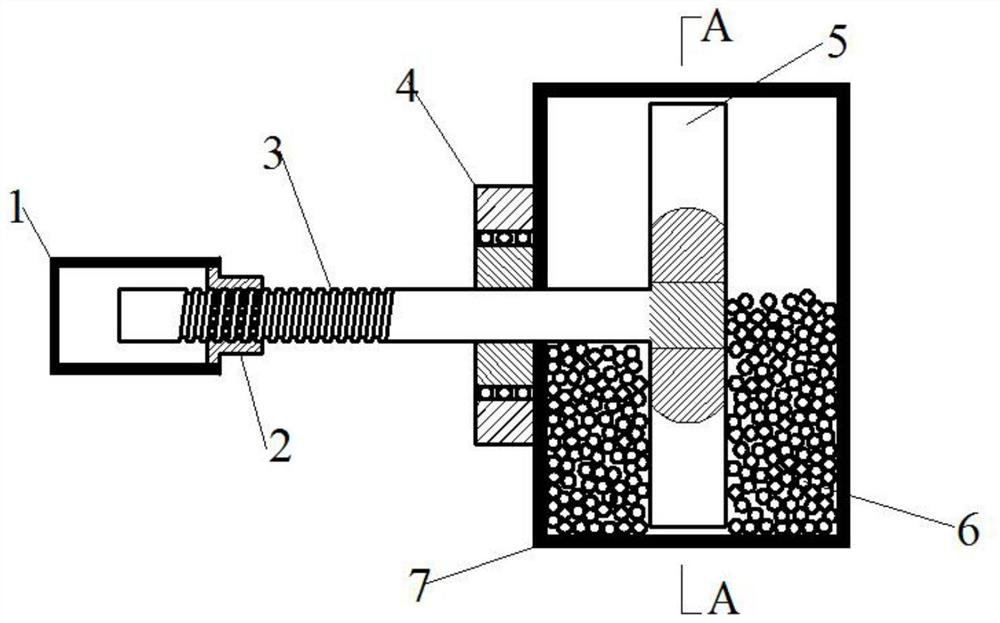

[0020] like figure 1 , figure 2 , image 3 and Figure 4 Shown is a particle inertial capacity damping device, which is mainly used between bridge piers and beams to play a role in shock absorption (vibration). It includes a metal casing one (1), a nut (2), a ball screw (3), a bearing (4), a flywheel (5), particles (6), a metal casing two (7) and an energy dissipation layer (8). Metal case one (1) has a size of 320mm×150mm×110mm and a thickness of 12mm. Metal case two (7) has a size of 320mm×320mm×320mm and a thickness of 12mm. The ball screw (3) has a diameter of 60mm and a length according to The maximum displacement of the controlled structure is determined. The flywheel (5) has a diameter of 280mm and a thickness of 150mm. The grooves on the flywheel (5) have different sizes according to the shock absorption requirements. The diameter of the particles (6) is 10mm. According to the shock absorption requirements, the metal casing two (7) The filling rate of the inner pa...

Embodiment 2

[0023] like figure 1 , figure 2 , image 3 and Figure 4Shown is a particle inertial capacity damping device, which is mainly used in the interstory of high-rise buildings or in the buffer layer of blasting structures to play the role of shock absorption (vibration). It includes a metal casing one (1), a nut (2), a ball screw (3), a bearing (4), a flywheel (5), particles (6), a metal casing two (7) and an energy dissipation layer (8). Metal case one (1) has a size of 530mm×180mm×150mm and a thickness of 17mm. Metal case two (7) has a size of 520mm×520mm×520mm and a thickness of 17mm. The ball screw (3) has a diameter of 110mm and a length according to The maximum displacement of the controlled structure is determined. The flywheel (5) has a diameter of 470mm and a thickness of 160mm. The grooves on the flywheel (5) have different sizes according to the shock absorption requirements. The diameter of the particles (6) is 15mm. According to the shock absorption requirements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com