An adjustable periodic damping steel rail

A technology of periodic damping and steel rails, applied in the direction of steel rails, tracks, roads, etc., can solve the problems of ineffective vibration and noise reduction measures, and achieve the effect of widening the bandgap range, easy parts, and strengthening the effect of vibration and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

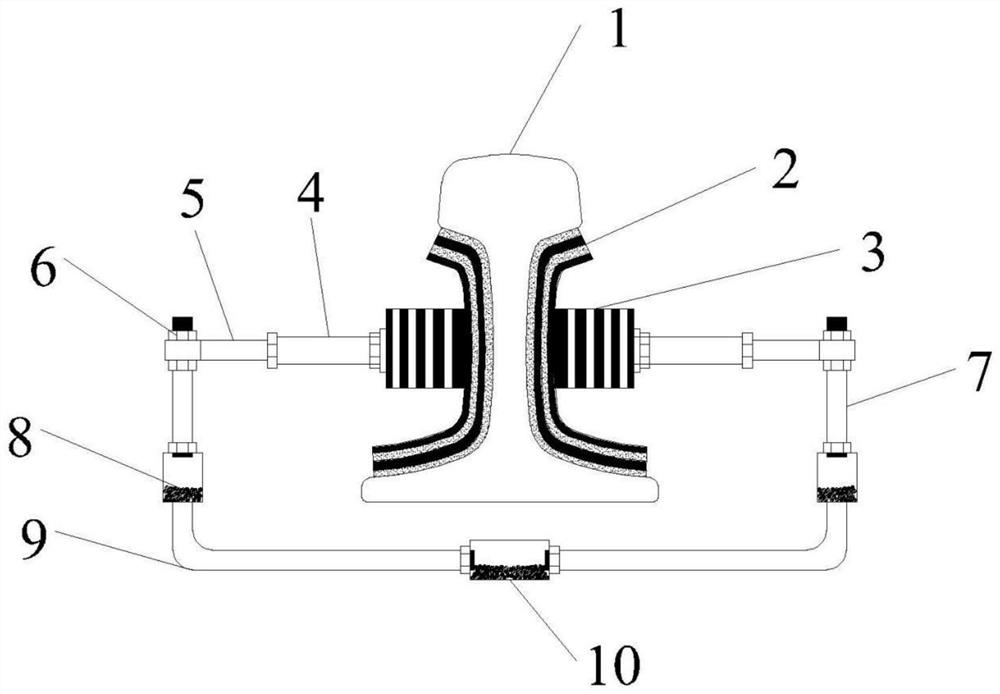

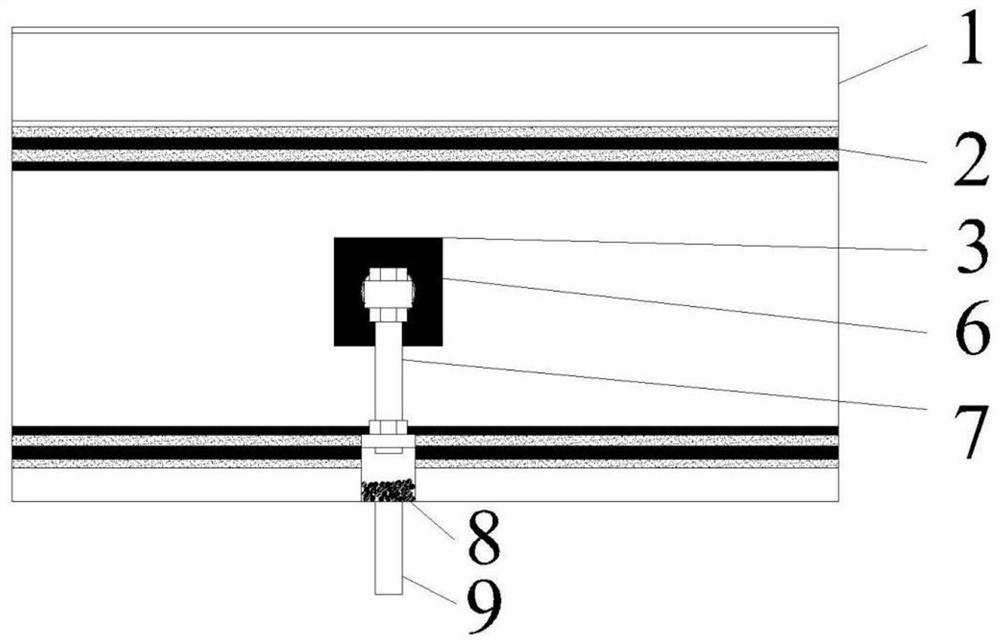

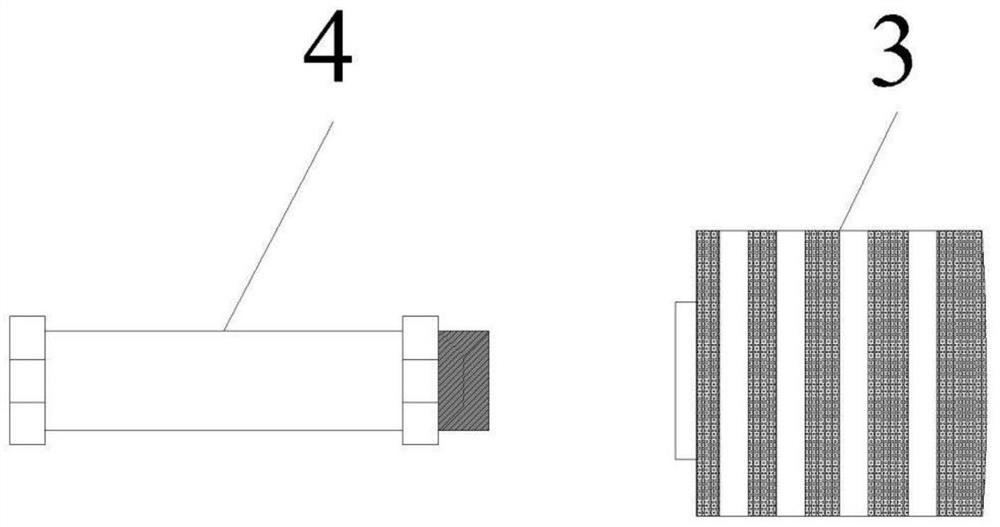

[0028] combine Figure 1-Figure 5 An adjustable periodic damping steel rail in this embodiment is described, which includes a rail body 1, a layered phononic crystal structure 2, a one-dimensional phononic crystal damping layer 3, a lateral vibration transmission rod 4, a belt Hole bolt rod 5, fastening nut 6, vertical vibration transmission rod 7, particle damper 8, crank connecting rod cavity 9, rectangular section cavity 10.

[0029] According to the principle of damping dynamic vibration absorption and vibration isolation, the layered phonon crystal structure and the one-dimensional phonon crystal vibration damping layer in the present invention can increase the vertical static stiffness and damping of the rail, and improve the attenuation of wheel-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com