Multi-speed pushing-in machine, air conditioner outdoor unit flexible production line and production method of air conditioner outdoor unit flexible production line

A frame and line body technology, applied in the flexible production line of air-conditioning external units and its production, and the field of double-speed push-in machines, can solve problems such as low applicability, decreased production efficiency, and easy failures, so as to reduce the risk of injury and reduce the risk of injury. The effect of equipment cost and wide range of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present application are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present application, and are not construed as limiting the present application.

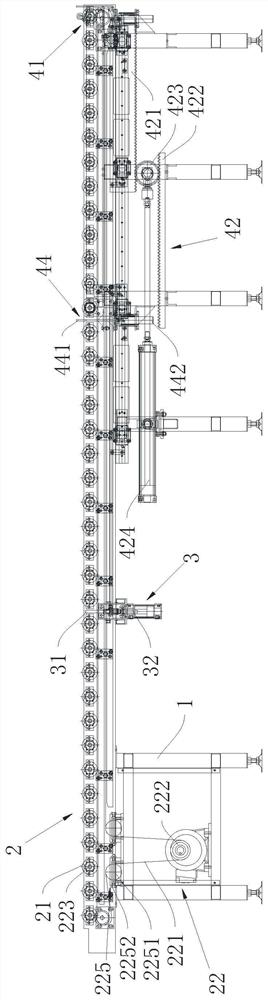

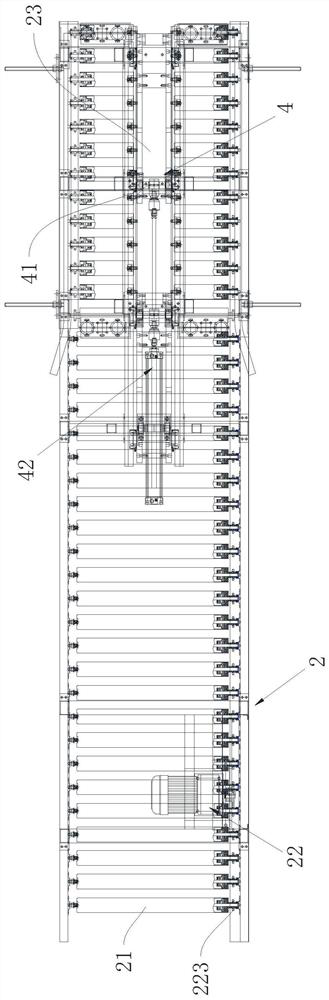

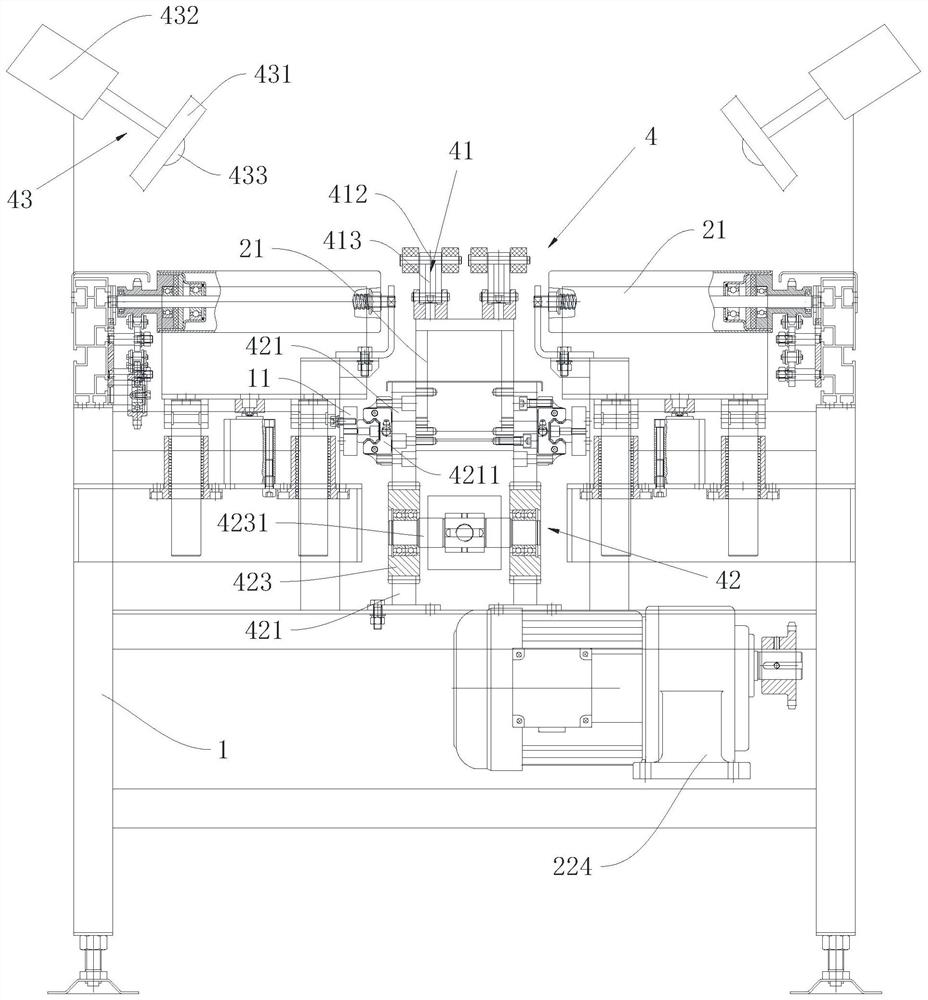

[0037] clear reference Figure 1 to Figure 4 , this application relates to a double-speed pusher, which is suitable for production lines in multiple industries such as air conditioners, refrigerators, washing machines, and water dispensers. High production efficiency and wide applicability.

[0038] The double-speed pushing machine includes a frame 1 and a conveying structure 2, a blocking structure 3, and a feeding structure 4 arranged on the frame 1, and the conveying structure 2 includes multiple structures arranged in the longitudinal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com