Containers for pushing out applying material

A coating material and coating material technology, applied in household containers, toiletry containers, cosmetic powder containers, etc., can solve the problem of insufficient push-out strength of the coating material, insufficient play of the screwing effect of the screw joint, etc. problem, achieve the effect of ensuring push-out strength and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in the following description, the same code|symbol is attached|subjected to the same or equivalent element, and repeated description is abbreviate|omitted.

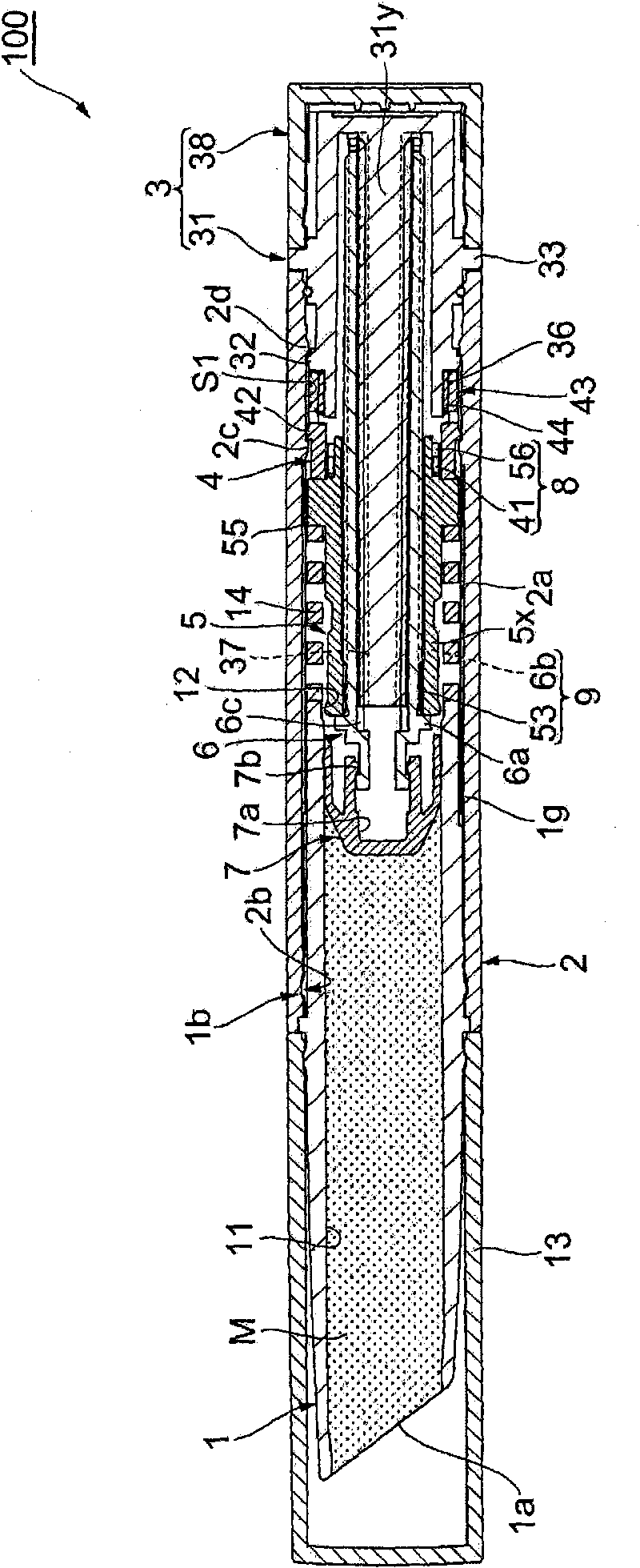

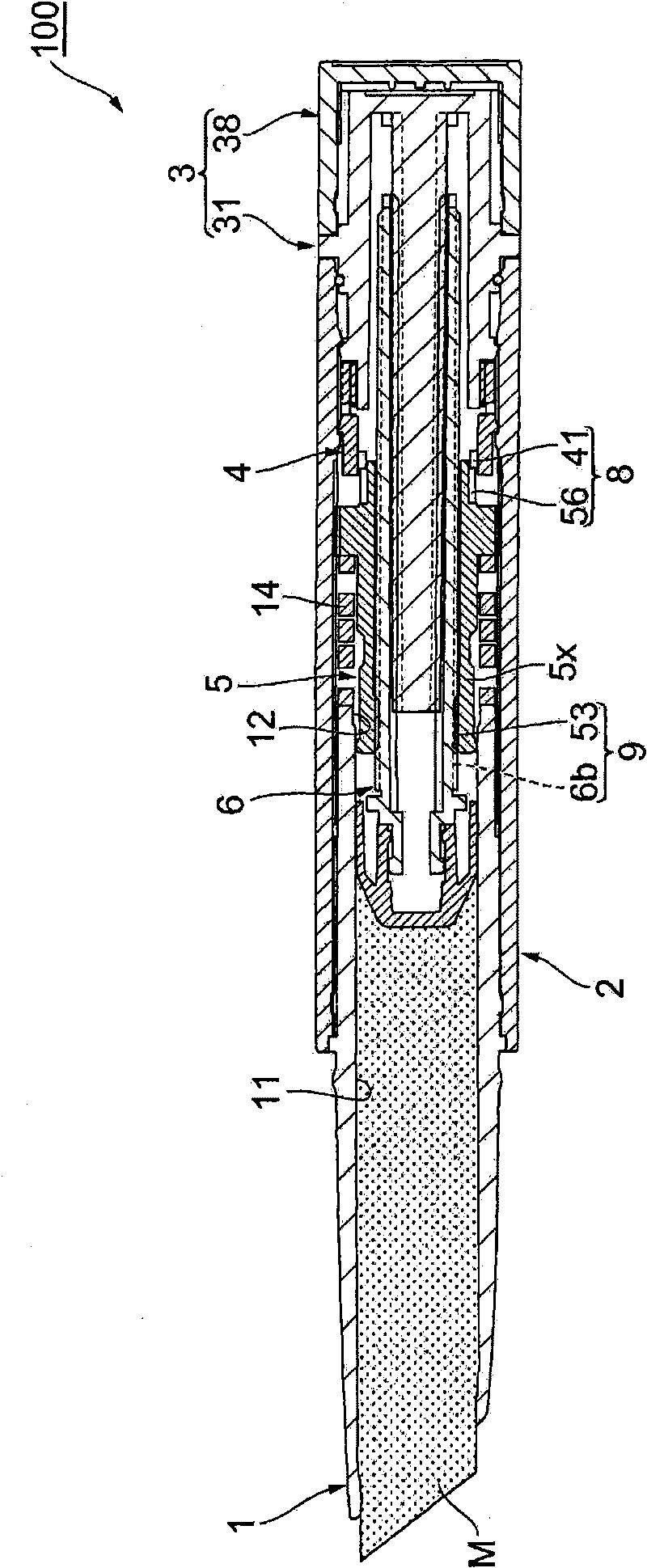

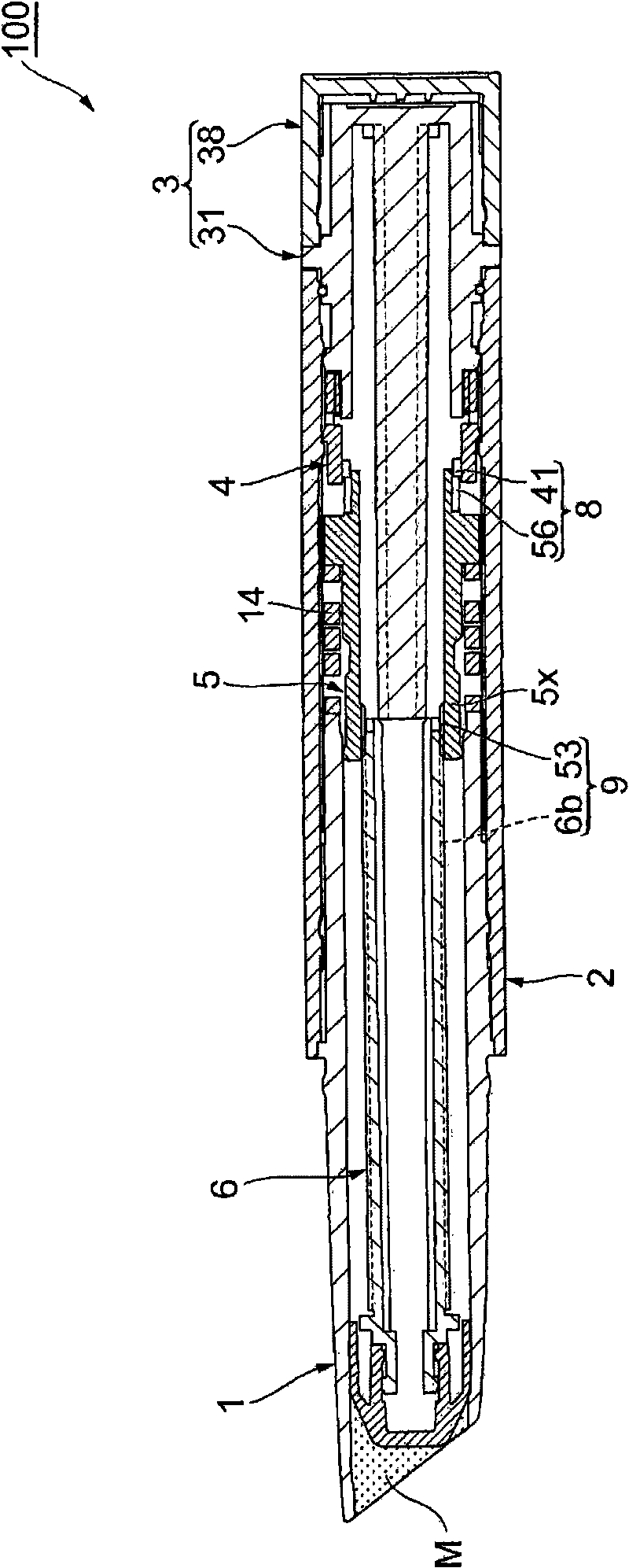

[0034] Figure 1 ~ Figure 3 It is a longitudinal sectional view showing each state of the coating material pushed out of the container according to one embodiment of the present invention, Figure 4 is a longitudinal sectional view showing the main body cylinder, Figure 5 ~ Figure 7 It is each figure which shows the main-body part of an operation cylinder, Figure 8 ~ Figure 11 are the diagrams showing the anti-rotation cylinders, Figure 12 , 13 It is each figure which shows the moving screw cylinder. Such as figure 1 As shown, the coating material ejection container 100 of this embodiment accommodates the coating material M and can push out or pull back the coating material M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com