Small-space guardrail hot galvanizing device

A technology of hot-dip galvanizing and small space, which is applied in the field of automation and can solve problems such as inability to purchase equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below.

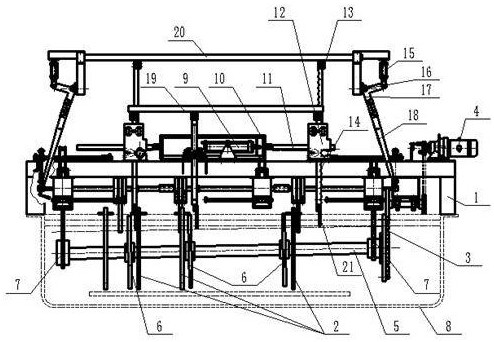

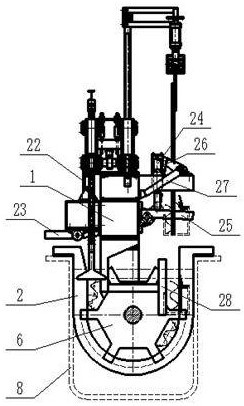

[0047] Such as Figure 1 to Figure 7 As shown, a small space guardrail hot-dip galvanizing equipment includes a zinc pot 8, a plurality of material baskets 2 and a main machine, and a plurality of material baskets 2 are arranged side by side in the zinc pot 8 and are supported by the zinc pot 8, and the main machine is horizontally arranged on the Above the zinc pot 8;

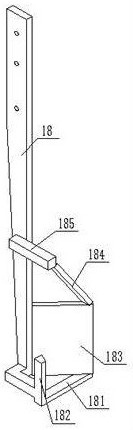

[0048] The main engine of the present invention comprises a main frame 1, two hooks 7 are arranged at both ends of the bottom of the main frame 1, a main shaft 5 is hung on the two hooks 7, and several flower discs 6 are arranged on the main shaft 5, and the distribution and setting of the flower discs 6 are according to the guardrail The length of the board is designed in advance. At least two faceplates 6 are used. The distance between the two faceplates 6 is smaller than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com