A yag welding machine component that improves output energy stability in peak state

A technology of output energy and stability, which is applied in the field of YAG welding machine components, can solve the negative effects of output energy stability, YAG rod damage, melting and other problems, and achieve the effects of improving output energy stability, safe and reliable use, and avoiding false triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

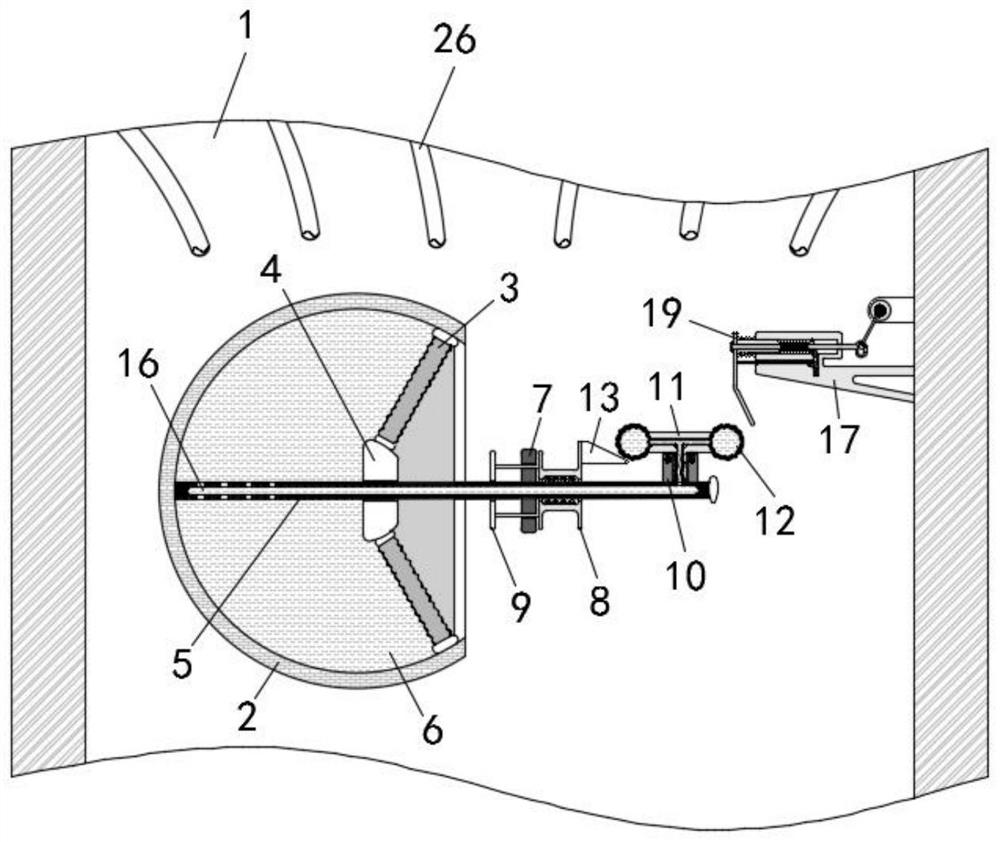

[0029] as attached figure 1 to the attached Image 6 shown:

[0030] The present invention provides a YAG welding machine assembly for improving output energy stability in a peak state, comprising a rod tube sleeve 1, a heat conduction shell 2 is fixedly installed inside the rod tube sleeve 1, and an elastic sealing film 3 is installed on the right end of the heat conduction shell 2, A movable block 4 is arranged at the center of the elastic sealing film 3 , a fixed shaft 5 penetrating the movable block 4 is fixedly connected to the inner wall of the heat-conducting shell 2 , a detection liquid 6 is filled between the heat-conducting shell 2 and the elastic sealing film 3 , and the fixed shaft 5 The outer side and the right side of the elastic sealing membrane 3 is fixedly sleeved with a limit ring 7, the right side of the limit ring 7 is slidably installed with a sliding seat 8, and the left end of the sliding seat 8 is fixedly connected to the left side of the limit ring 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com