Flow instrument shell running type isolation spraying device

A technology of flow meter and spraying device, applied in spraying device, spraying room and other directions, can solve the problems of not conforming to the trend of the times, cost cost, paint harm to human body, etc., and achieve the effect of saving labor cost, saving physical strength and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

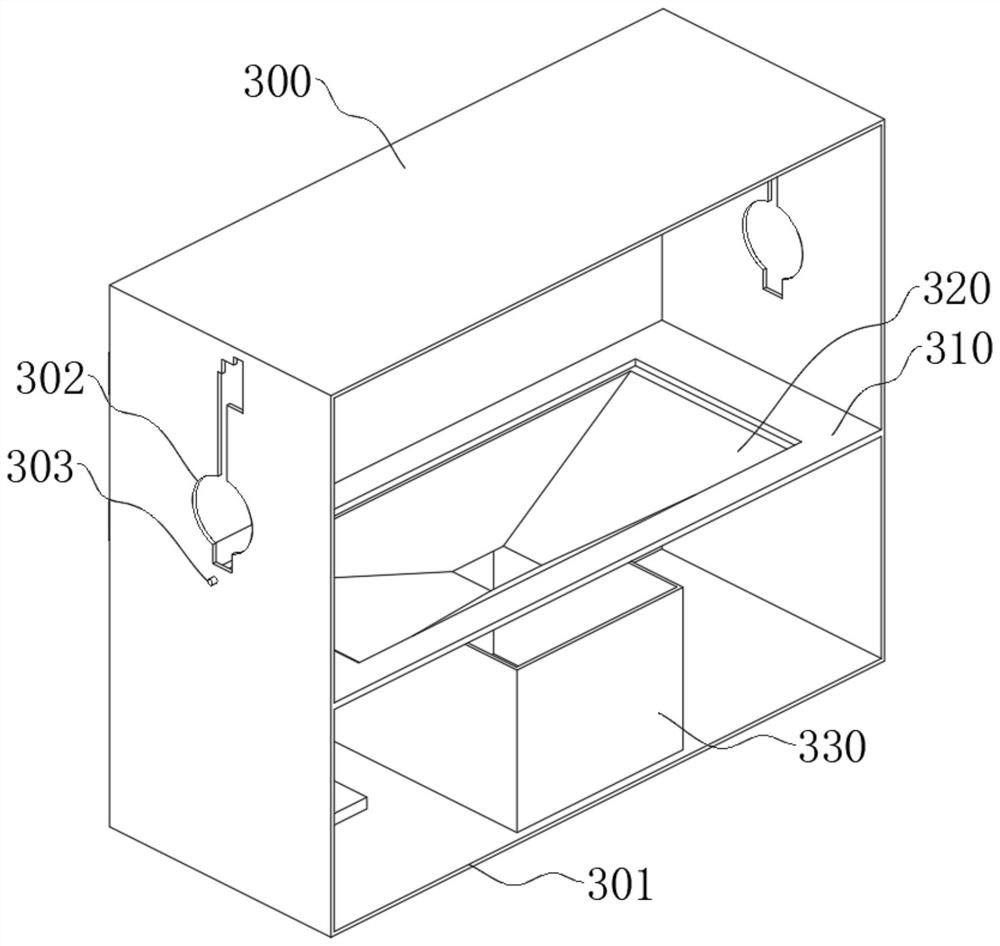

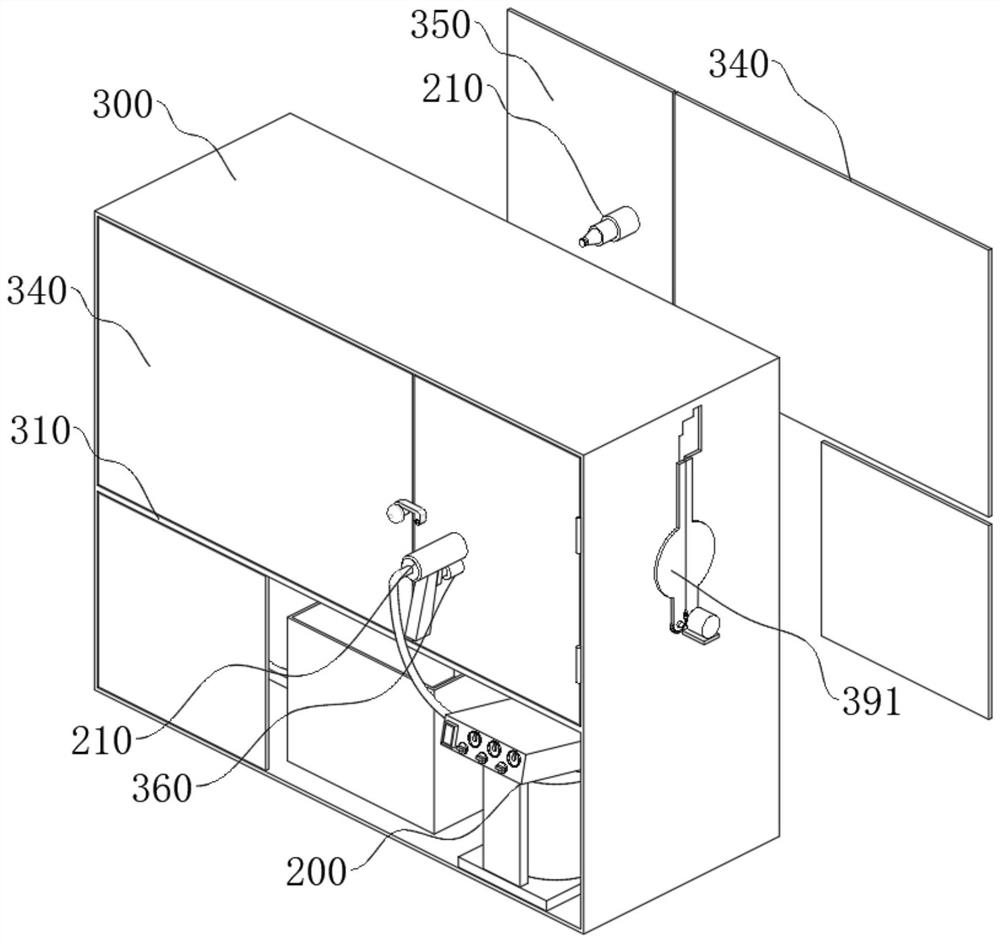

[0046] see Figure 1 to Figure 14 As shown, the present invention provides a flowing water-type isolated spraying device for a flow meter housing, which includes a paint baking room 100, a number of spraying machines 200 and spray guns 210 installed therein. Plastic-sprayed wall panels have good sealing and thermal insulation performance. Its interior is mainly composed of air supply system, exhaust system, heating system, electric control system, etc. After spraying, the flow meter shell enters the paint room and is heated by the heating system inside. , allowing the paint to cure on the outer surface of the flow meter housing. The main working part of the spraying machine is a double-acting pneumatic-hydraulic booster pump. After the compressed air is pumped into the pump, the piston moves to the upper or lower end of the cylinder, thereby sucking the paint in the paint bucket at the rear of the spraying machine, and passing through the high-pressure hose. Send it to the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com