Beneficiation process of high-carbon high-oxidation micro-fine particle gold ore

A high-oxidation, fine-grained technology, used in flotation, solid separation, grain processing, etc., can solve the problems of improvement, complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

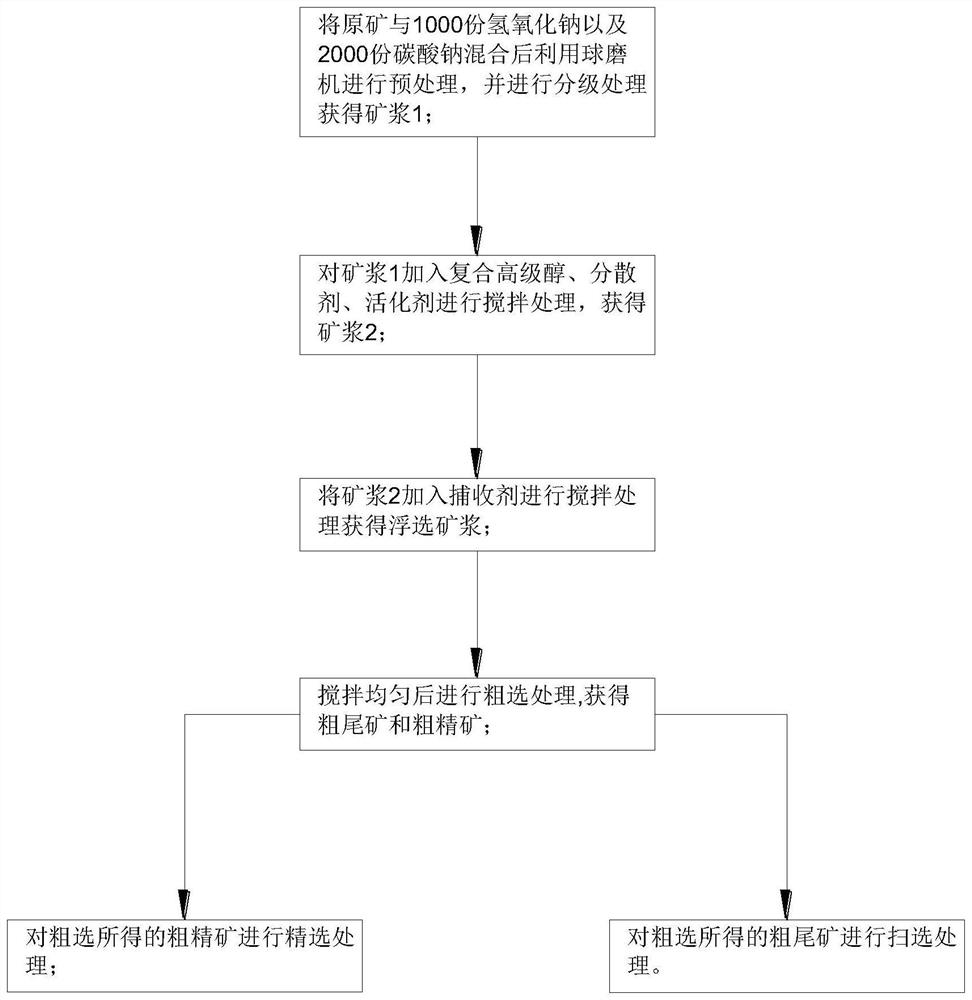

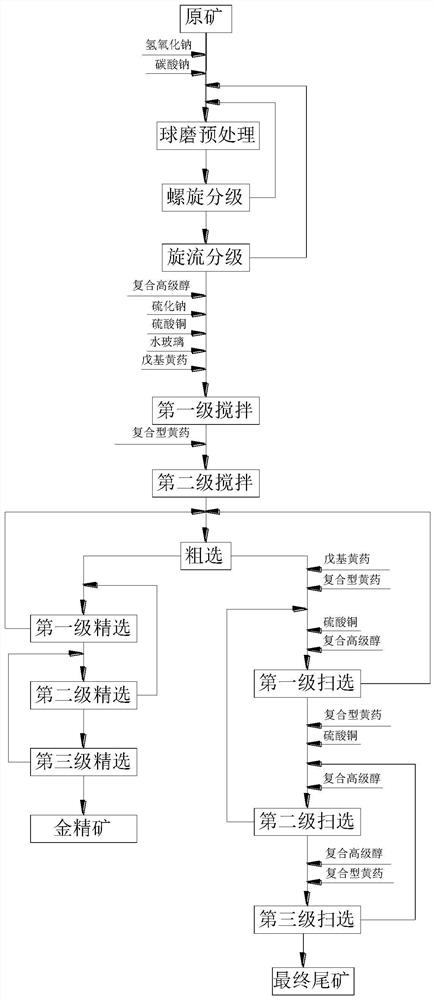

[0041] like figure 1 As shown, the beneficiation process of a kind of high-carbon high-oxidation fine-grained gold ore provided by the embodiment of the present application comprises the following steps:

[0042] S1: Mix the raw ore with 1000 parts of sodium hydroxide and 2000 parts of sodium carbonate, pretreat it with a ball mill, and perform classification treatment to obtain pulp 1;

[0043] S2: adding composite higher alcohol, dispersant, and activator to pulp 1 for stirring treatment to obtain pulp 2;

[0044]S3: adding the pulp 2 to the collector for stirring treatment to obtain the flotation pulp;

[0045] S4: After stirring evenly, carry out roughing treatment to obtain rough tailings and rough concentrate;

[0046] S4-1: Concentrating the rough concentrate obtained from roughing;

[0047] S4-2: Sweeping the rough tailings obtained from roughing.

[0048] In some embodiments of the present invention, based on the idea of simple, feasible and low-cost design, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com