Beneficiation method for directional enrichment of precious metal

A beneficiation method and directional enrichment technology, which can be used in flotation, solid separation and other directions, and can solve problems such as difficulty in achieving low-cost and efficient enrichment and beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

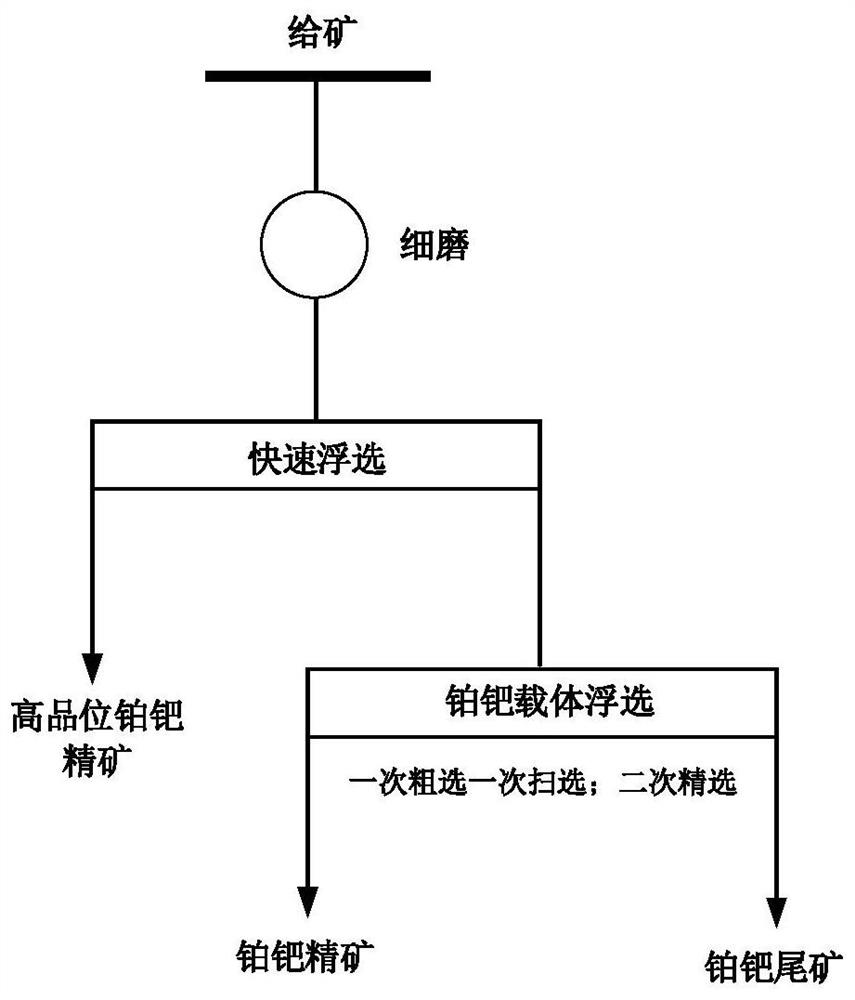

[0031] This embodiment provides a series of beneficiation methods for directional enrichment of precious metals, such as figure 1 , the specific process is as follows.

[0032] (1) Fine grinding: Grinding to -0.020mm accounts for 80% to 94%;

[0033] (2) Rapid flotation: Adjust the pulp to a concentration of 25% to 35%, add collectors and foaming agents in sequence, and perform rapid flotation to obtain high-grade platinum-palladium concentrate;

[0034] (3) Platinum and palladium carrier flotation: add regulator, collector and foaming agent in sequence, and adopt a closed circuit of primary roughing, primary sweeping and secondary selection for platinum and palladium carrier flotation.

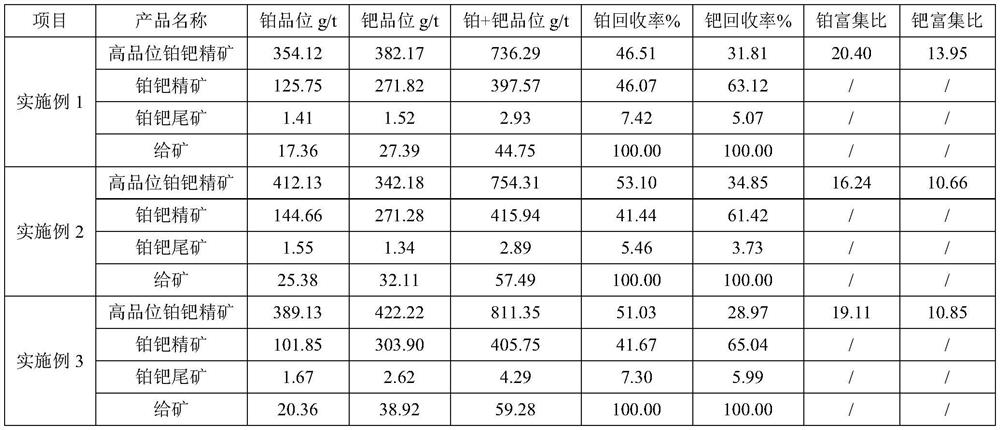

[0035] Among them, the ore grinding to -0.020mm accounts for 80%, 85%, and 94% respectively in Examples 1 to 3, and the adjusted pulp concentration is 25%, 35%, and 30%, respectively.

[0036] The ore supply information, selected reagents and dosage, other condition controls, and ore dressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com