Method for treating solid waste obtained after adsorption of starch wastewater with activated carbon

A technology of activated carbon adsorption and treatment methods, applied in separation methods, chemical instruments and methods, filter regeneration, etc., can solve the problems of wastewater generation and long regeneration time, and achieve the effect of increasing the rate of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

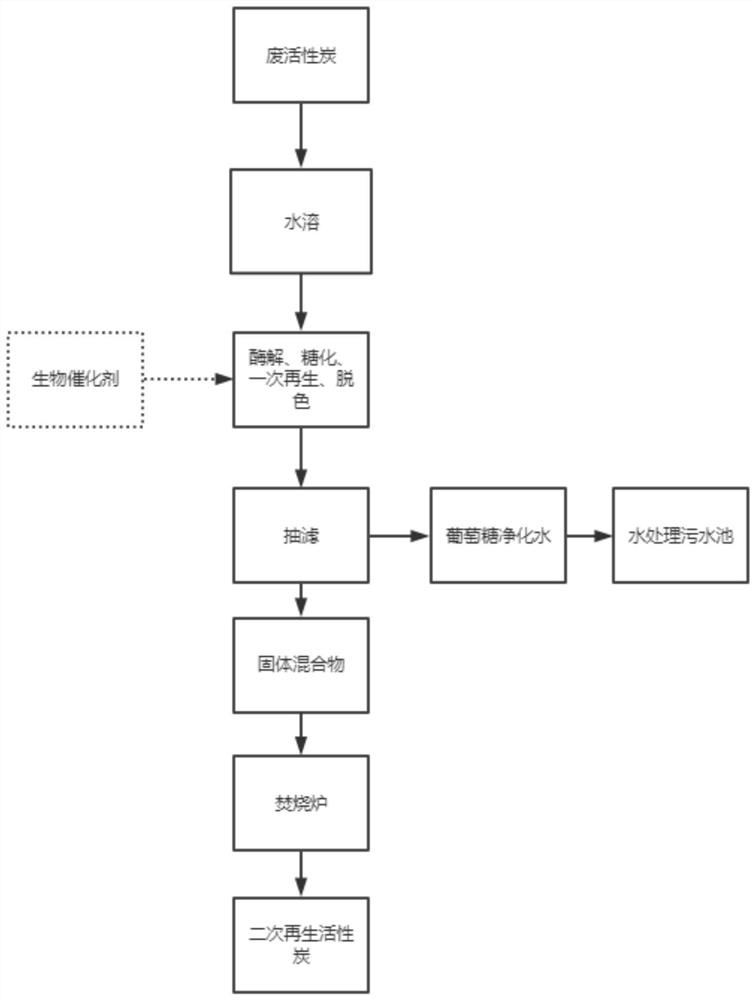

Method used

Image

Examples

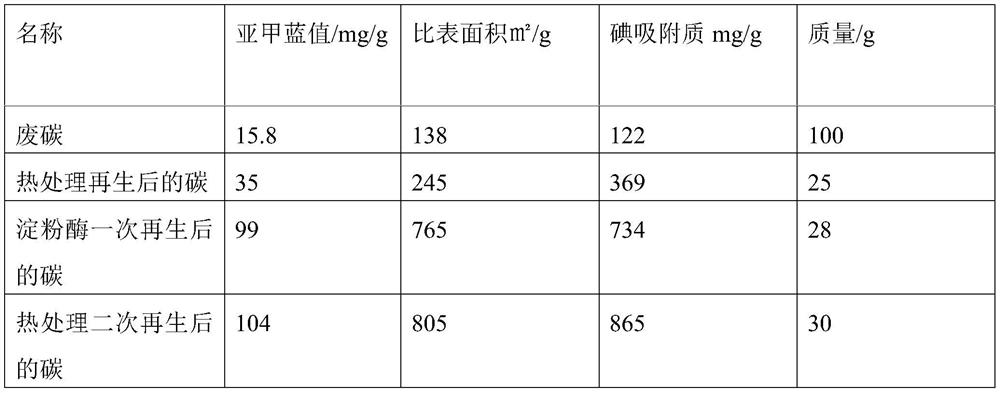

Embodiment 1

[0029] The waste activated carbon obtained from a pharmaceutical company has a black block appearance, high moisture content, and white deposits on the surface.

[0030] Pre-experiment 1: After mechanically pulverizing 100g of large-grained activated carbon, place it in a muffle furnace for calcination at a high temperature of 800°C for 8 hours. Due to the low ignition point of the adsorbed starch-like organic matter, which is 300°C, the activated carbon spontaneously ignites in the furnace. All remaining active carbon 1g was burnt to ash.

[0031] Pre-experiment 2: After crushing 100g of large-grained activated carbon clusters, dissolve them in water with twice the mass, stir them evenly with a magnetic stirrer, and obtain activated carbon and dissolved water after filtration. The activated carbon was oven-dried at 120°C for 24 hours, and it was found that the weight of the activated carbon was reduced by 50% (from 100g to 50g). After calcination at 800°C in the muffle furnac...

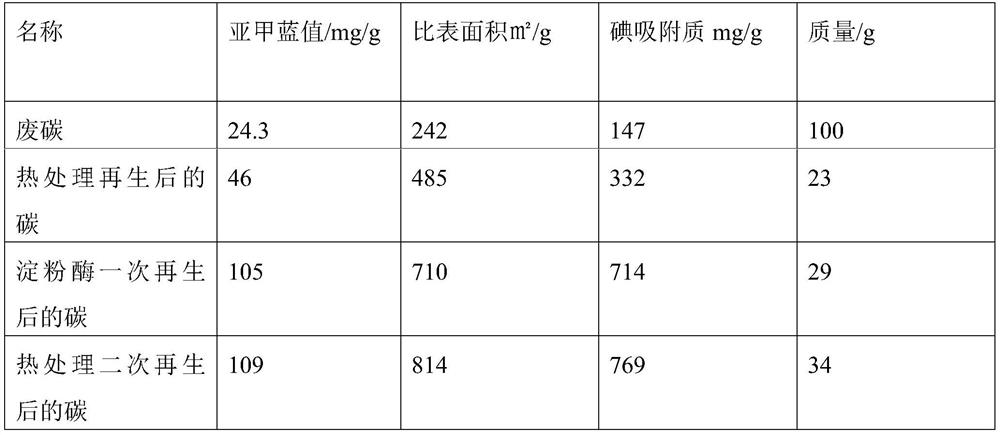

Embodiment 2

[0039] The waste activated carbon obtained from a pharmaceutical company has a black block appearance, high moisture content, and white deposits on the surface.

[0040] Pre-experiment 1: directly crush 100g of large-grained activated carbon mechanically, and place it in a muffle furnace for calcination at a high temperature of 800°C for 8 hours. Due to the low ignition point of the adsorbed starch organic matter, which is 300°C, the activated carbon spontaneously ignites in the furnace, and the remaining 1 g of activated carbon was completely burned to ash.

[0041] Pre-experiment 2: Break 100g of the large-grained activated carbon cluster into water with twice the mass, stir it evenly with a magnetic stirrer, and filter to obtain activated carbon and dissolved water. Activated carbon was oven-dried at 120°C for 24 hours, and it was found that the weight loss of activated carbon was 54% (from 100g to 46g). After calcination at 800°C in the muffle furnace for 8 hours, the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com