Nutrition bowl batch adding equipment for biological cultivation foundation soil

A technology for nutrient bowls and equipment, which is applied to the field of batch installation of equipment for nutrient bowls for biological cultivation base soil, and can solve the problems of high investment, affecting seedling efficiency, and disordered placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

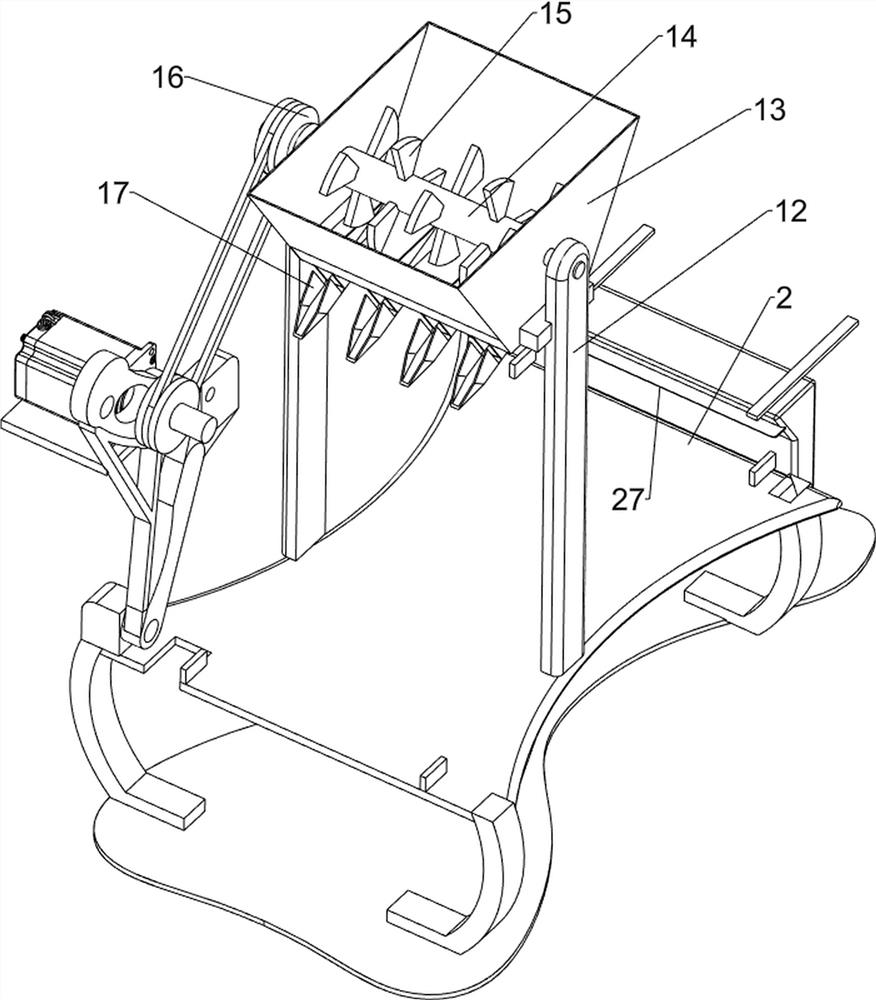

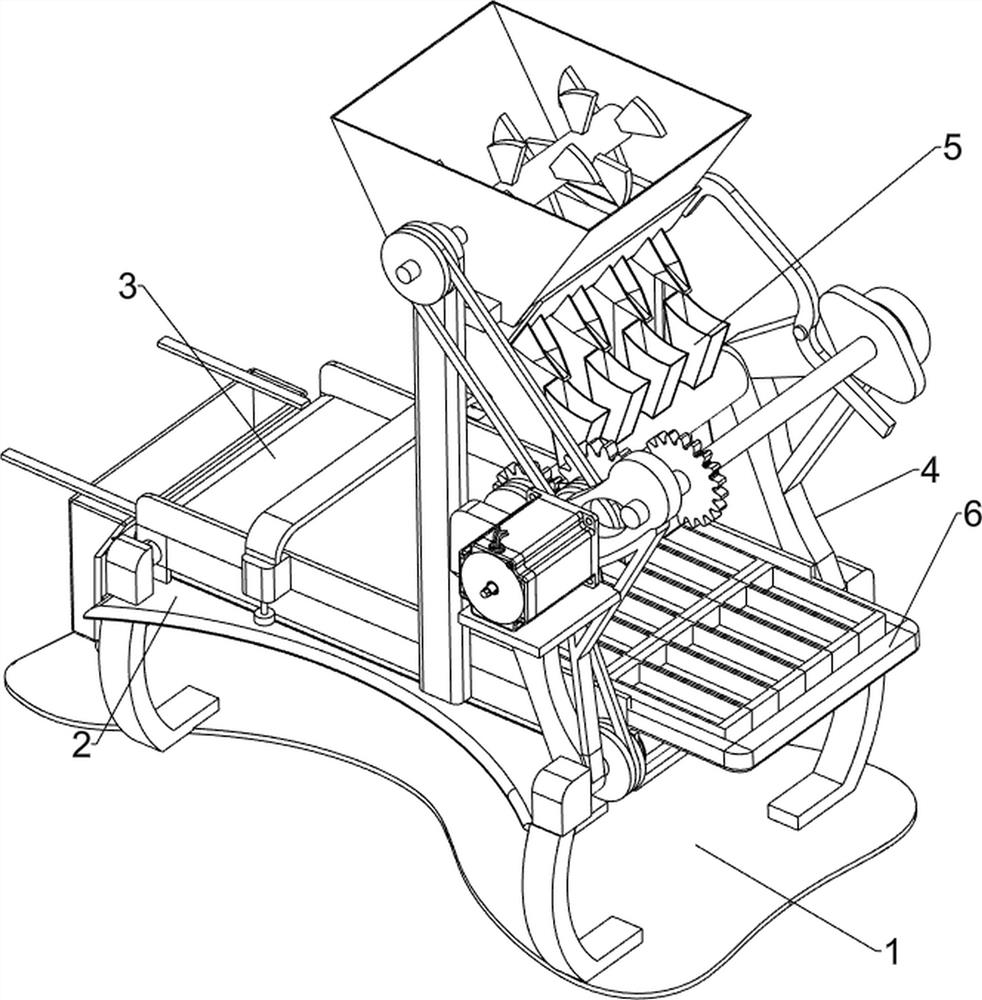

[0027] Such as figure 1 , figure 2 with image 3 As shown, a batch installation equipment for nutrient bowls for biological cultivation base soil includes a bottom plate 1, a workbench 2, a conveying mechanism 3, a mounting plate 4, a feeding mechanism 5 and a placement frame 6, and a workbench is arranged on the top of the bottom plate 1 2. The top of the workbench 2 is provided with a conveying mechanism 3, and the rear part of the right side of the conveying mechanism 3 is provided with a mounting plate 4. The mounting plate 4 is provided with a blanking mechanism 5. The blanking mechanism 5 cooperates with the conveying mechanism 3, and the conveying mechanism 3 Placement box 6 is placed.

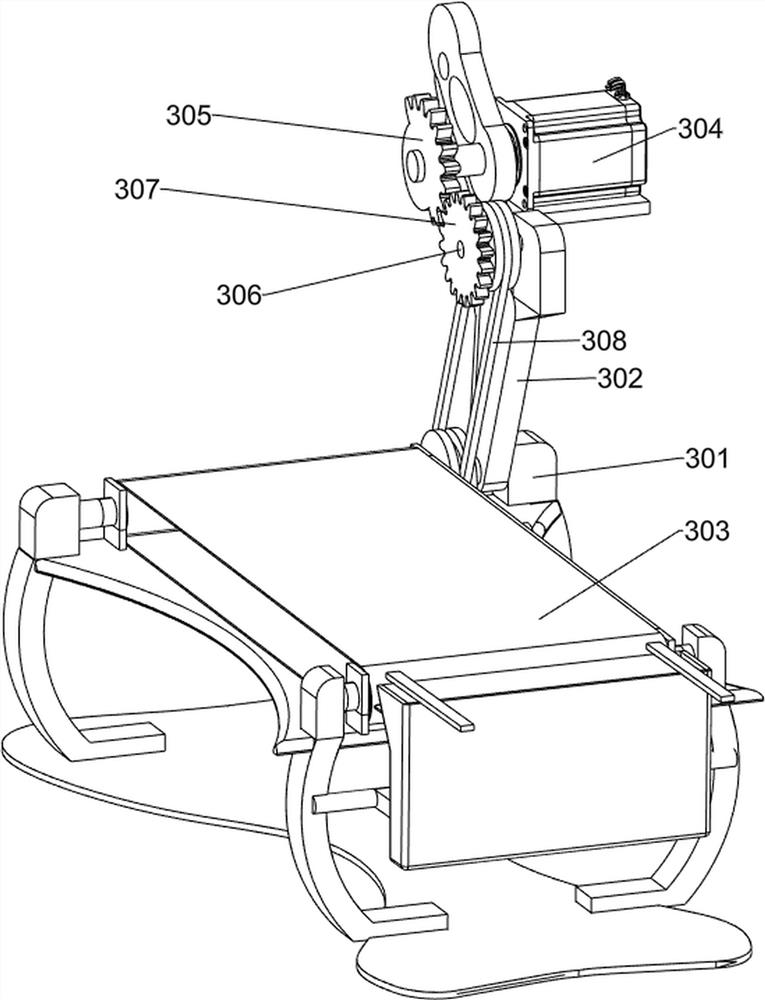

[0028] The conveying mechanism 3 includes a fixed seat 301, a mounting bracket 302, a conveyor belt 303, a rotating motor 304, a missing gear 305, a rotating shaft 306, a first gear 307 and a first belt assembly 308, and the four corners of the top of the workbench 2 are provided wit...

Embodiment 2

[0032] Such as Figure 4 , Figure 5 with Image 6 As shown, on the basis of Embodiment 1, it also includes a support plate 7, a baffle plate 8, a positioning block 9 and a nut 11, and the four corners of the top of the workbench 2 are provided with a support plate 7, and the support plate 7 on the same side A baffle 8 is arranged between them, and the two baffles 8 are symmetrical about the central axis of the conveyor belt 303, and positioning blocks 9 are arranged on the two baffles 8, and a material partition 10 is slidably arranged between the two positioning blocks 9, The bottom of the material partition 10 is a threaded rod, and the threaded rod at the bottom of the material partition 10 is screwed with a nut 11 .

[0033] By adjusting the material partition 10 and fixing it by the nut 11, the conveyor belt 303 can drive the placement frame 6 to convey to the left, and the material partition 10 can scrape the surface of the nutrition bowl in the placement frame 6 flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com