Method for operating an internal combustion engine, and controller for carrying out the method

An internal combustion engine and controller technology, applied in engine control, internal combustion piston engine, combustion engine and other directions, can solve problems such as uneconomical, save time and cost, and achieve the effect of long maintenance time interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

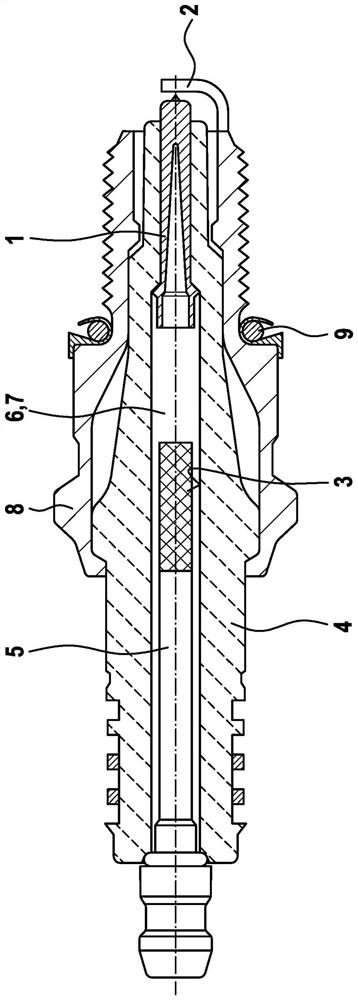

[0025] figure 1 The spark plug shown is used in an internal combustion engine with external ignition in order to ignite the fuel-air mixture with a spark between two electrodes 1 , 2 . To this end, a high-voltage pulse is conducted via a conductor insulated from the motor to the first electrode 1 , from which the spark then jumps over to the other electrode 2 . The fuel-air mixture is then ignited due to the thermal energy of the crossing spark.

[0026] The first electrode 1 is accommodated in the central cavity 3 of the sleeve-shaped insulator 4 and is therefore also referred to as central electrode or central electrode. The central electrode consists of a nickel alloy and has a copper core. The other electrode 2 is a ground electrode 2 arranged spaced apart from the first electrode 1 . This other electrode also consists of a nickel alloy. The spark plug technology and service life can be influenced by the arrangement and / or geometry of the electrodes.

[0027] In the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com