Chip capacitor processing equipment

A technology for processing equipment and capacitors, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as large footprint, inability to directly connect stamping machines, incompatibility between stamping machines and pin cutting devices, etc., to improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

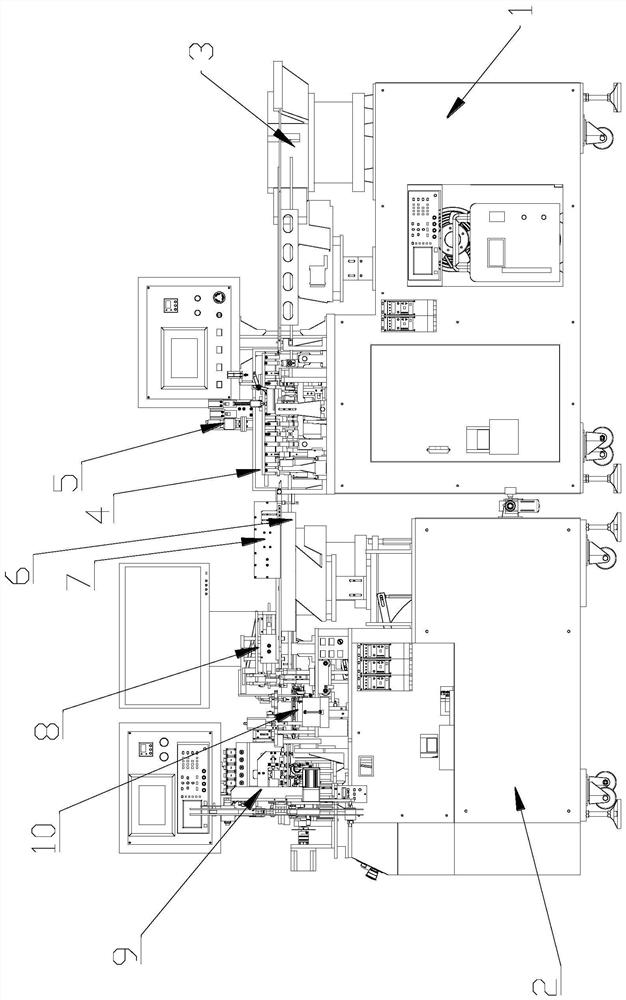

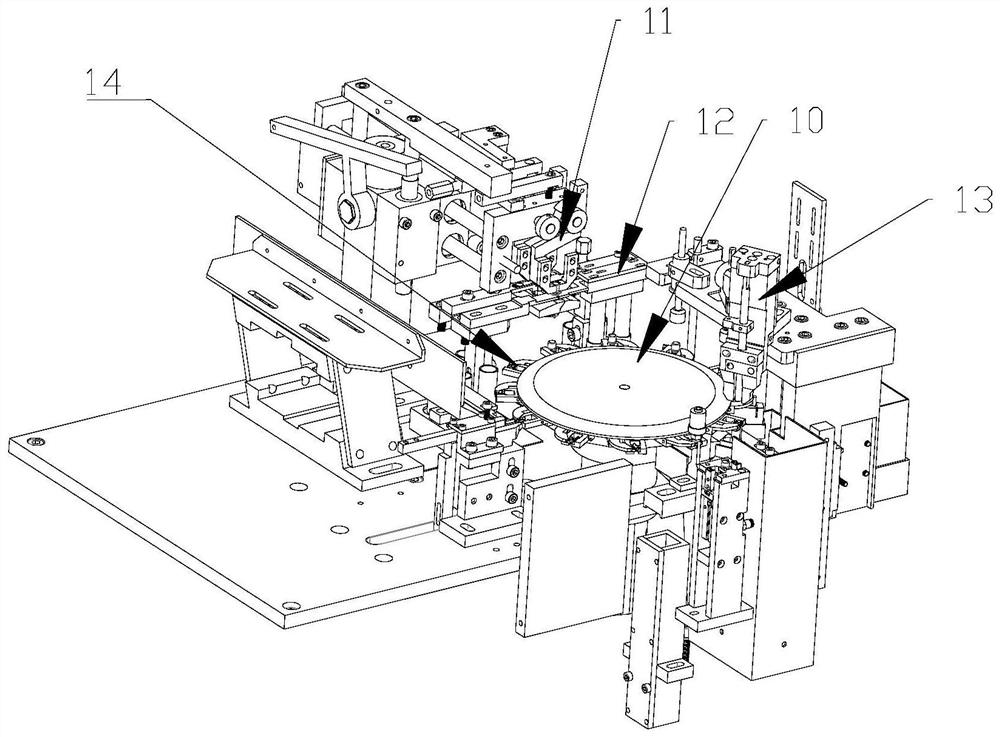

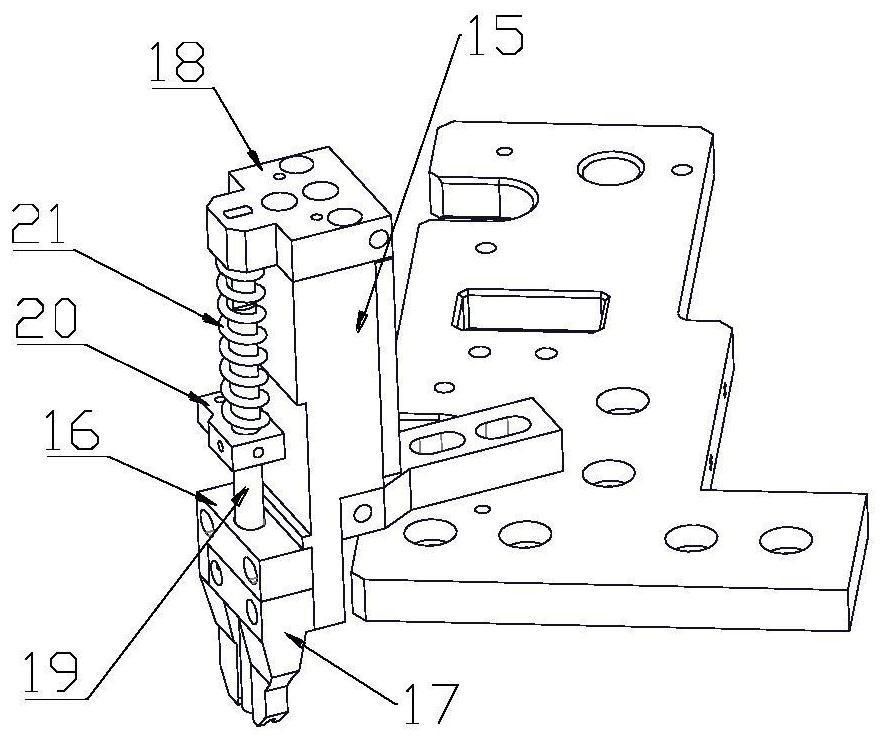

[0030] Such as Figure 1-5 As shown, a processing equipment for chip capacitors includes a printing device 1 at the front end and a lead cutting device 2 at the rear end, a transmission section 6 is arranged between the printing device 1 and the packaging device, and the transmission The section 6 is provided with a UV curing device 7 for curing printing ink for stamping;

[0031] The stamping device 1 includes a feeding vibrating plate 3, a first transport module 4 and a stamping mechanism 5, the stamping mechanism 5 is arranged at the first transporting module 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com