Efficient water distribution spray head for cooling tower

A technology for distributing water nozzles and cooling towers, which is applied in the direction of water shower coolers, heat exchange equipment, direct contact heat exchangers, etc., which can solve the problem that the sputtering range cannot meet the design requirements, the cooling nozzle sputtering range is reduced, and it is impossible to carry out Uniform water distribution and other issues to achieve the effect of maintaining the impact force, maintaining the sputtering range, and increasing the water outlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

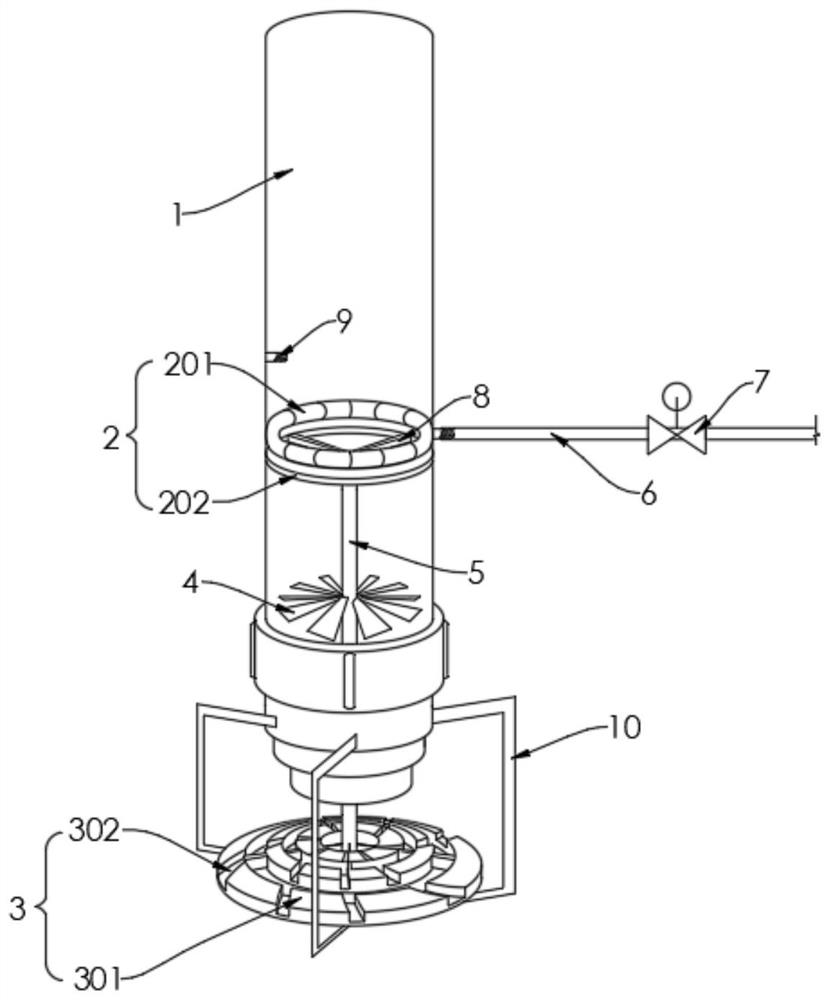

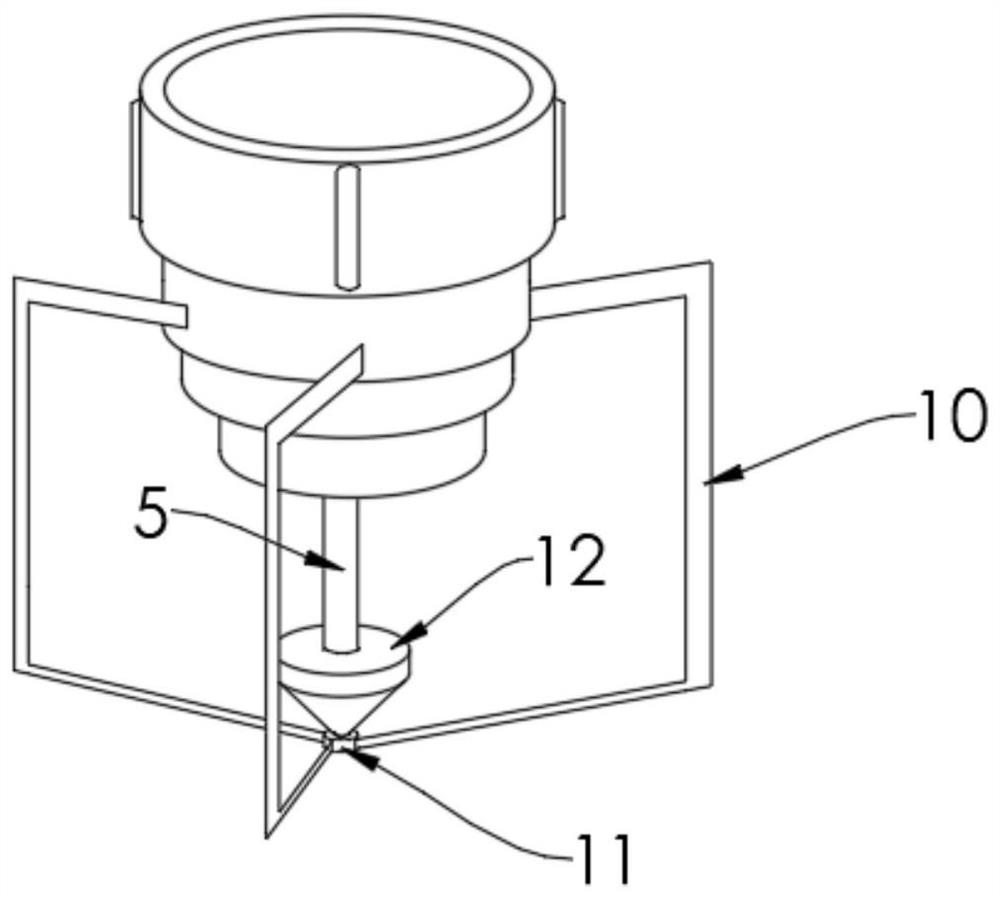

[0032] refer to Figure 1-3 , a high-efficiency water distribution nozzle for cooling towers, including

[0033] Water distribution pipe 1;

[0034] The water pressure regulating mechanism 2 includes a reinforcing ring plate 202 fixed on the inner wall of the water distribution pipe 1, and the upper fixing device of the reinforcing ring plate 202 has a corresponding annular air bag 201;

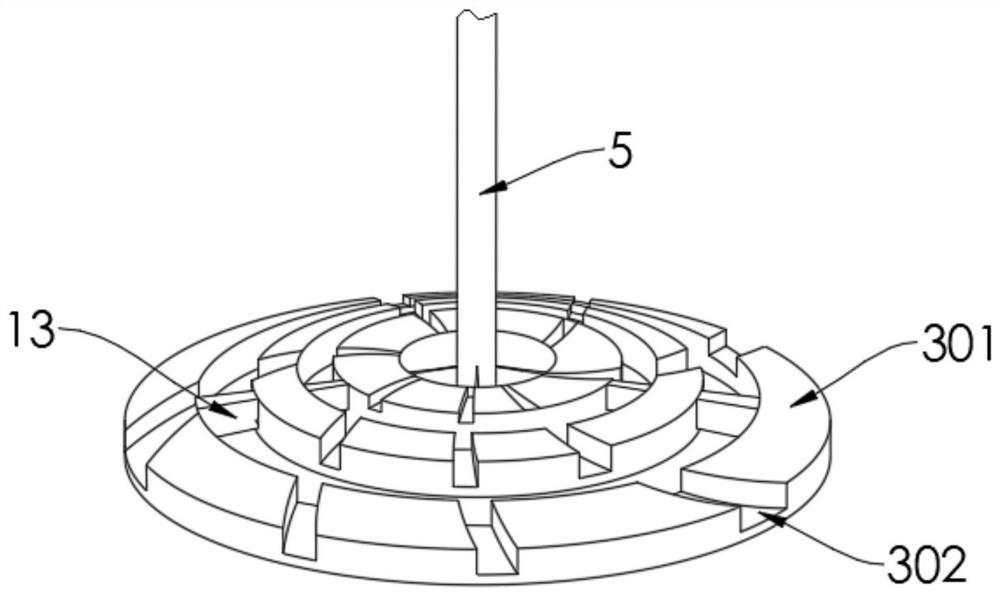

[0035] The rotating water distributor 3 is installed on the water outlet end of the water distribution pipe 1. The rotating water distributor 3 includes three annular water distribution rings 301 arranged in concentric circles. The height of the outer annular water distribution ring 301 is low At the height of the annular water distribution ring 301 located on the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com