A high and low pressure bypass control system for intermediate reheat units in the power generation industry

A bypass system, high-pressure bypass technology, applied in control systems, machines/engines, steam generation, etc., can solve the problems of complex layout of high- and low-pressure bypass systems, difficulty in adding and removing loads of steam turbines, and complicated operation operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

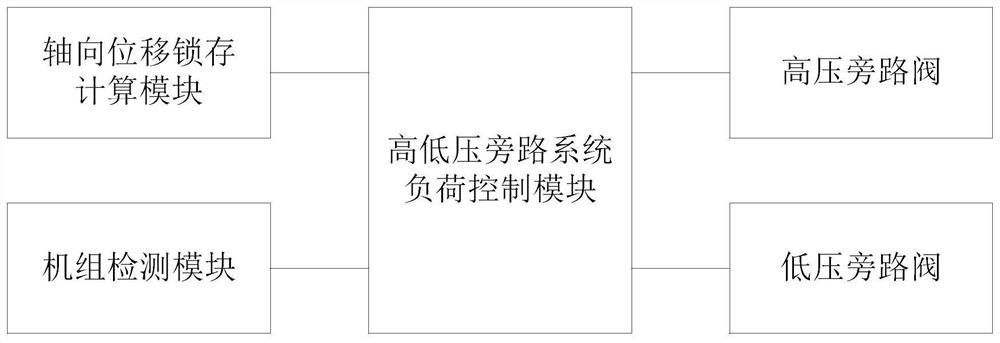

[0028] figure 1 It is the principle block diagram of the high and low pressure bypass control system of the intermediate reheat unit used in the power generation industry of the present invention.

[0029] In this embodiment, as figure 1As shown, this embodiment provides a high and low voltage bypass control system for the waste-to-energy industry, which includes: a high and low voltage bypass system load control module, which is electrically connected to the high and low voltage bypass system load control module The axial displacement latch calculation module, unit detection module, high pressure bypass valve and low pressure bypass valve; wherein the high and low pressure bypass system load control module is adapted to lock the current axial displacement value according to the operating state of the steam turbine, and control the corresponding The bypass valve performs loading or unloading actions; the axial displacement latching calculation module is adapted to calculate t...

Embodiment 2

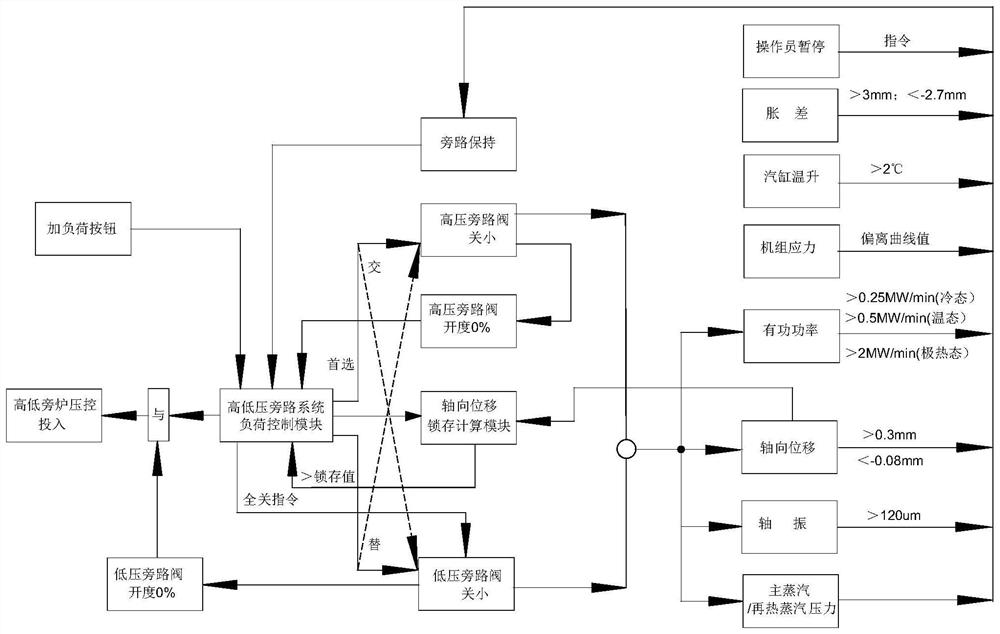

[0043] Figure 5 It is a flow chart of the automatic loading method of boiler paralleling and steam of the present invention.

[0044] On the basis of Example 1, as Figure 5 As shown in the figure, this embodiment provides an automatic load loading method for an intermediate reheat unit after the boiler is combined with steam. Bypass valve; real-time detection of unit load rise rate, cylinder temperature rise rate, change in expansion difference and unit stress. When the rise rate of cylinder temperature and change in expansion difference reach the set value, the high-pressure bypass valve stops and closes at a low value. Warm up with this opening; calculate the difference between the increased axial displacement and the locked axial displacement value, when the difference reaches the set value, control the high-pressure bypass valve to maintain the current opening, and start to close the corresponding low-pressure bypass When the cylinder temperature rise rate and the expa...

Embodiment 3

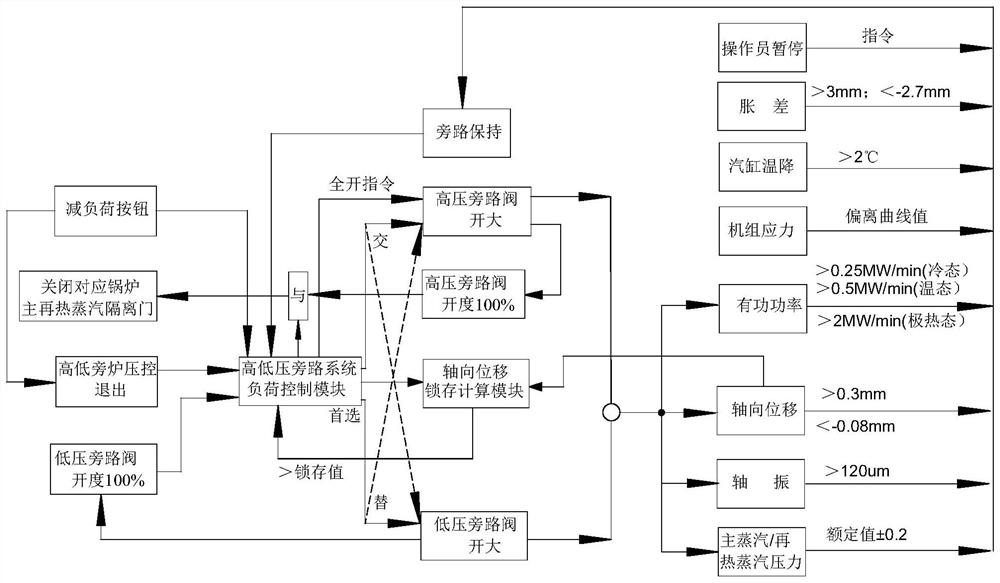

[0048] Image 6 It is a flow chart of the automatic load shedding method of the boiler decoupling of the present invention.

[0049] On the basis of the above-mentioned embodiment, as Image 6 As shown in the figure, the present embodiment provides an automatic load shedding method for decommissioning a boiler, which includes: after a boiler to be decommissioned and out of service is given, locking the current axial displacement value of the steam turbine, and gradually opening the corresponding low-pressure side at a set rate. Bypass valve; real-time detection of unit load drop rate, cylinder temperature drop rate, change in expansion difference and unit stress, when any parameter reaches the corresponding set value, the low pressure bypass valve stops opening and keeps at this opening to warm up the machine ; Calculate the difference between the axial displacement reduction and the locked axial displacement value, when the difference reaches the set value, control the low-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com