A Construction Technology of Gangue Filling-Grouting Reinforcement in Deep Mine without Coal Pillars

A technology of grouting reinforcement and construction technology, which is applied in the direction of filling, mining equipment, earthwork drilling and mining, etc., can solve the problems of insufficient airtightness of toxic and harmful gases, and achieve reasonable and significant particle gradation, good economy, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

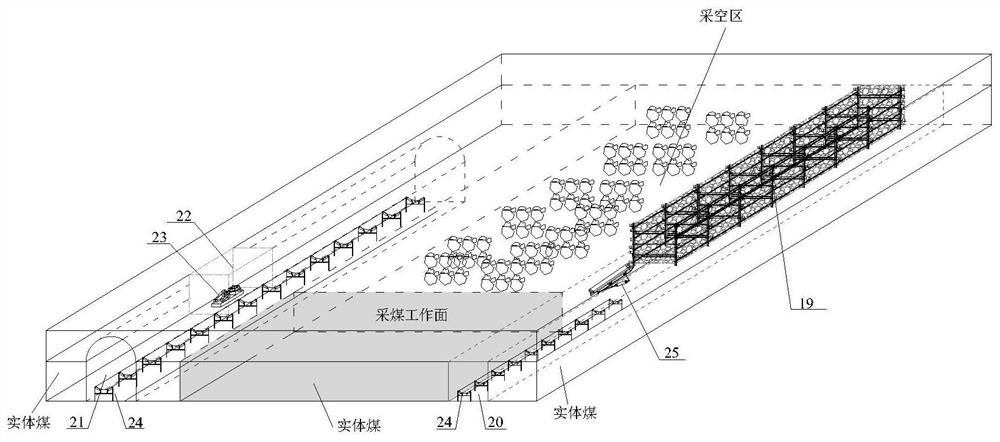

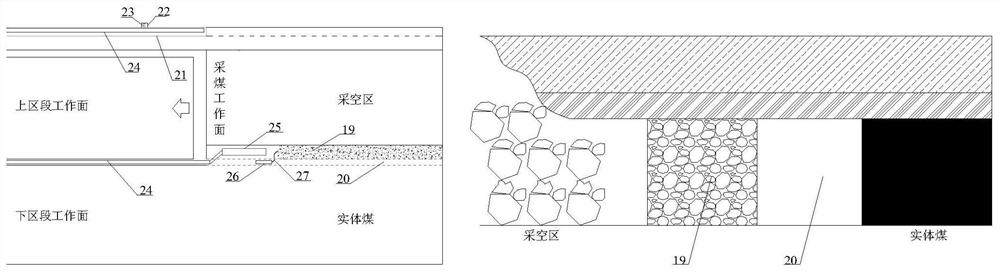

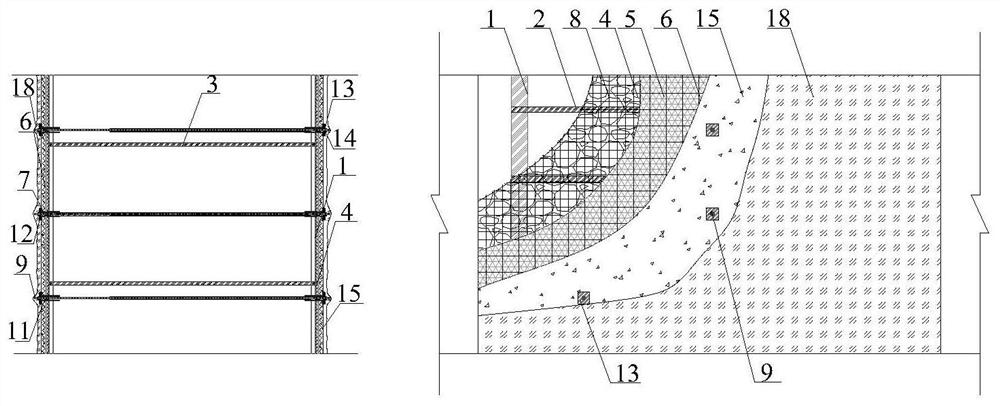

[0034] Such as figure 1 As shown, the gangue filling-grouting reinforcement deep well without coal pillar gobside entry construction process of the present invention uses gangue filling wall frame, gangue crushing and transportation system and grouting reinforcement system;

[0035] Specific steps include:

[0036] Step 1. The roadway that is being excavated on the adjacent working face, that is, the roadway that is closest to the gob-side entry and is being excavated is the excavation roadway. Use the gangue crushing and transportation system to crush the large pieces of gangue generated by the excavation roadway before transporting to Gob-side lanes;

[0037] Step 2, build a filling wall frame next to the goaf side of the original roadway, and the size of the retained roadway is consistent with the original roadway;

[0038] Step 3: The crushed g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com