Efficient concrete conveying device

A conveying device and concrete technology, which is applied in the direction of filtration circuit, filtration separation, construction, etc., can solve problems such as troublesome concrete construction, difficult long-distance pumping, and blockage of conveying equipment, so as to realize long-distance conveying, improve conveying efficiency, reduce Possible effects of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

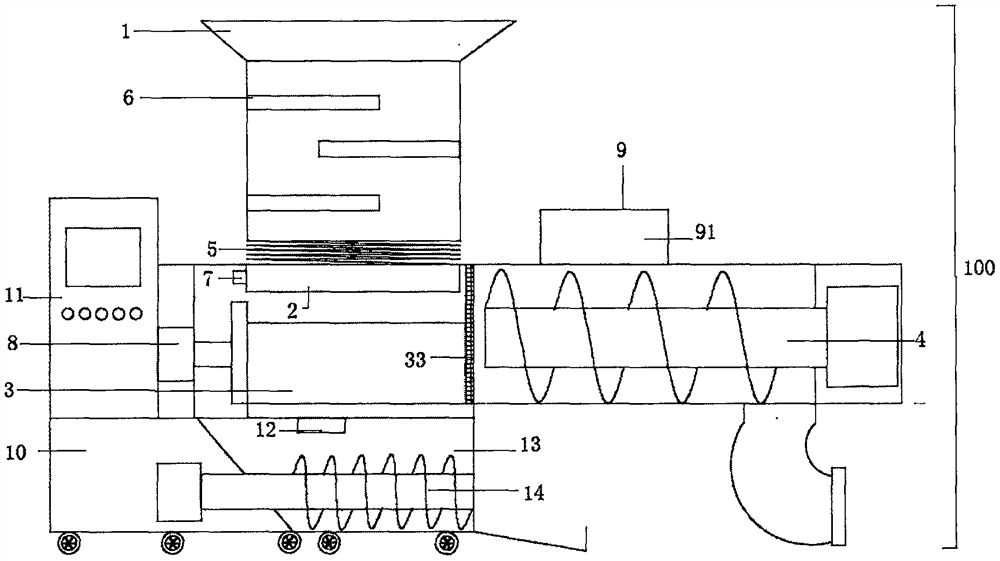

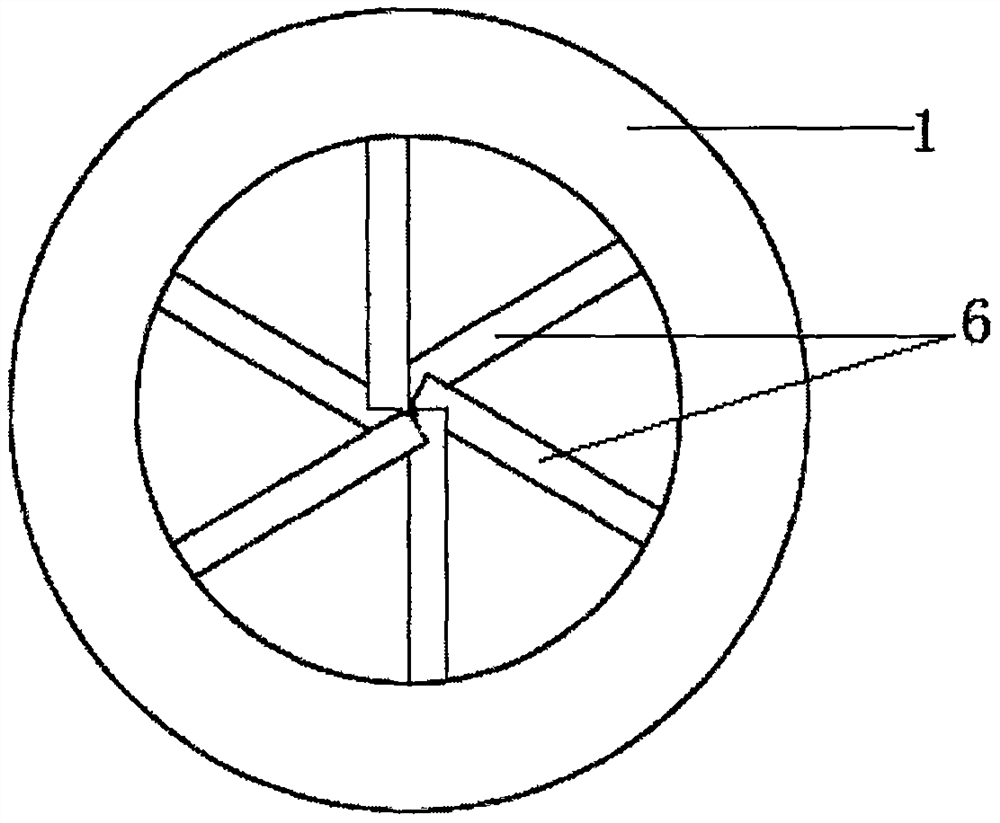

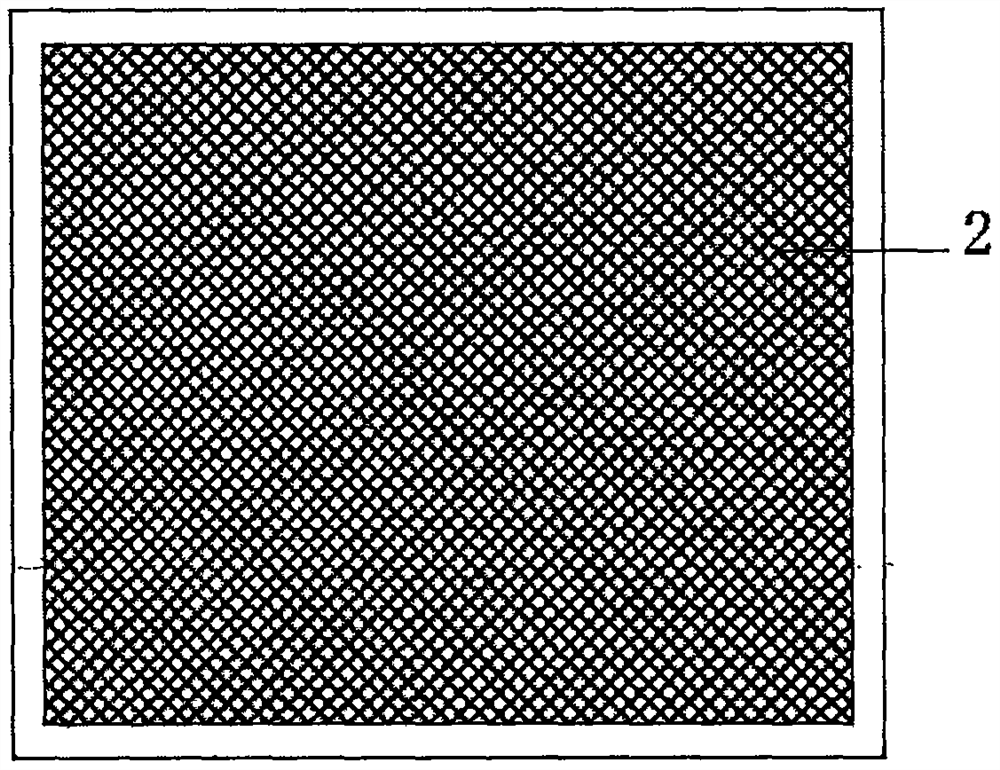

[0031] Such as Figure 1-6 As shown, this embodiment provides a high-efficiency concrete conveying device 100, which includes a buffer feeding hopper 1, a vibrating filter screen 2, a filter press assembly 3 and a conveying auger 4 arranged in sequence along the material conveying direction, and the buffer feeding hopper 1 passes through The buffer spring 5 is installed above the vibrating filter screen 2, a number of buffer rods 6 are arranged in the buffer feed hopper 1, and each buffer rod 6 is evenly distributed along the axial and circumferential directions of the buffer feed hopper 1, so as to realize a staggered arrangement, and the concrete After the material enters, it can not only slow down the downward speed under the action of the buffer rod 6 to achieve the buffer effect, but also the multi-stage buffer rod 6 can break up the concrete step by step and evenly; Vibrator 7, vibrator 7 is used for vibrating and vibrating filter screen 2, improves the filter efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com