Wool warp yarn continuous tension adjusting method without displacement sensor

A technology of displacement sensor and tension adjustment, which is applied in the direction of textile, textile, papermaking, loom, etc. It can solve the problems that the current position of the pressure roller cannot be fed back, the controllability of the pile height is affected, and the quality of the towel fabric is lowered, so as to avoid Inaccurate tension detection, low cost of use, stable and controllable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

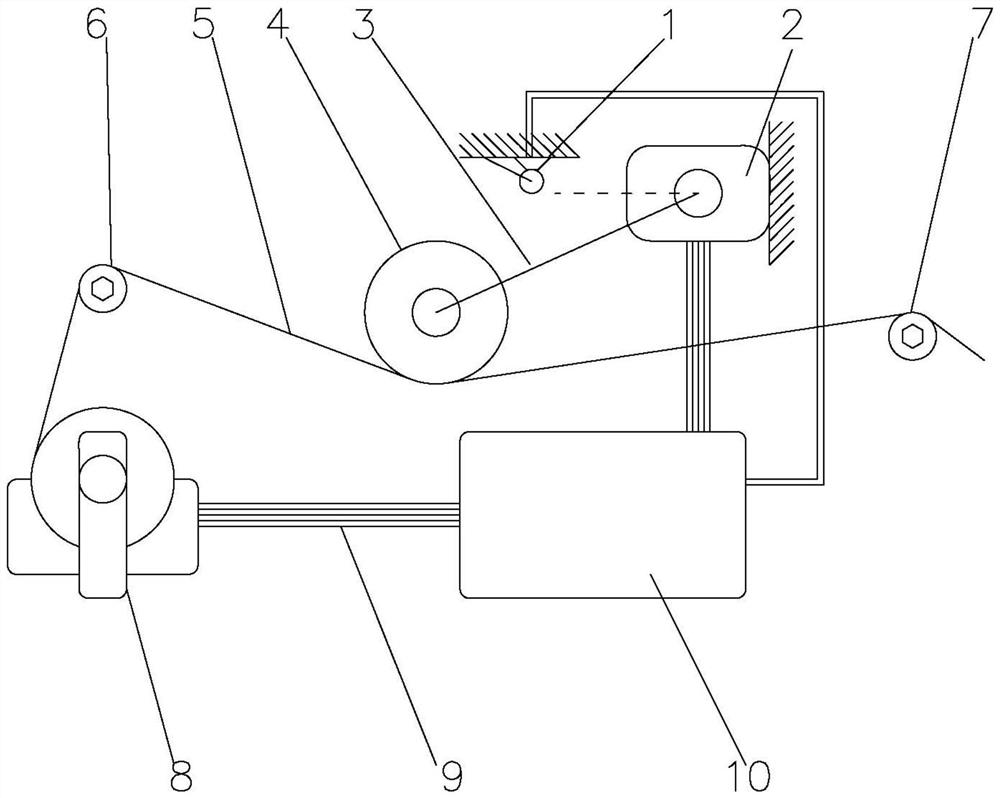

[0035] Please refer to the attached figure 1 As shown, it is a continuous tension adjustment device for wool warp yarns without a displacement sensor of the present invention, which is used for continuous tension adjustment of wool warp yarns 5. 4. Rolling bearing I6, rolling bearing II, yarn shaft 8 and controller 10 are composed of several parts.

[0036] Wherein, the limit switch 1 is arranged on one side of the servo motor 1 .

[0037] One end of the connecting rod 3 is connected to the servo motor 2 and driven to rotate by the servo motor 2 ; the other end of the connecting rod 3 is pivotally connected to the pressing roller 4 . The connecting rod 3 can abut against the limit switch 1 driven by the servo motor 2 .

[0038] The rolling bearing I6 is arranged on one side of the pressing roller 4 ; the rolling bearing II7 is arranged on the other side of the pressing roller 4 .

[0039] The wool warp yarn 5 is wound on the yarn shaft 8 . The wool warp yarn 5 is supported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com