Hollow glass production line

A glass production line and hollow technology, applied in the field of glass production equipment, can solve problems such as the incomplete alignment of the aluminum frame and the glass, the impact of the quality of the insulating glass, and the increase of the aluminum frame and the glass, so as to reduce errors, improve quality, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-4 The application is described in further detail.

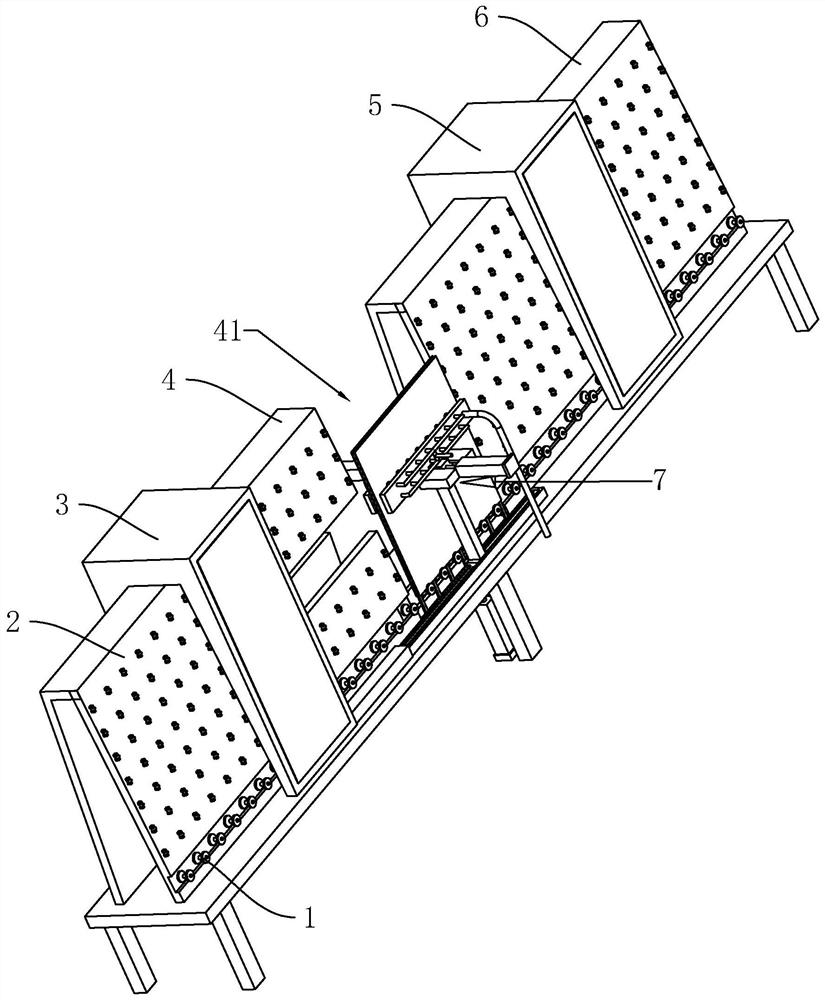

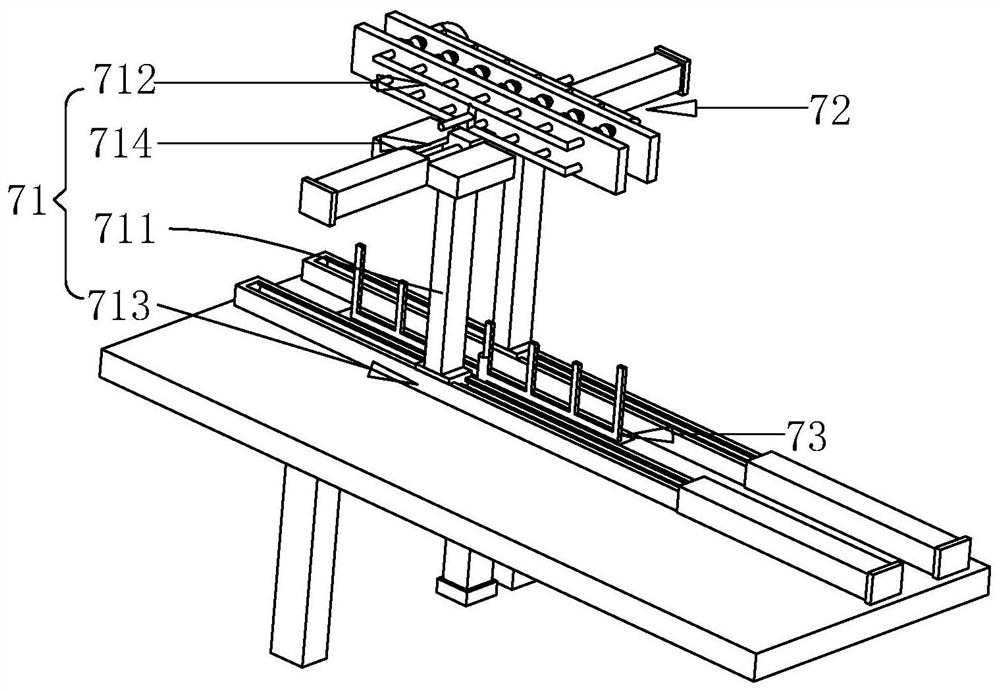

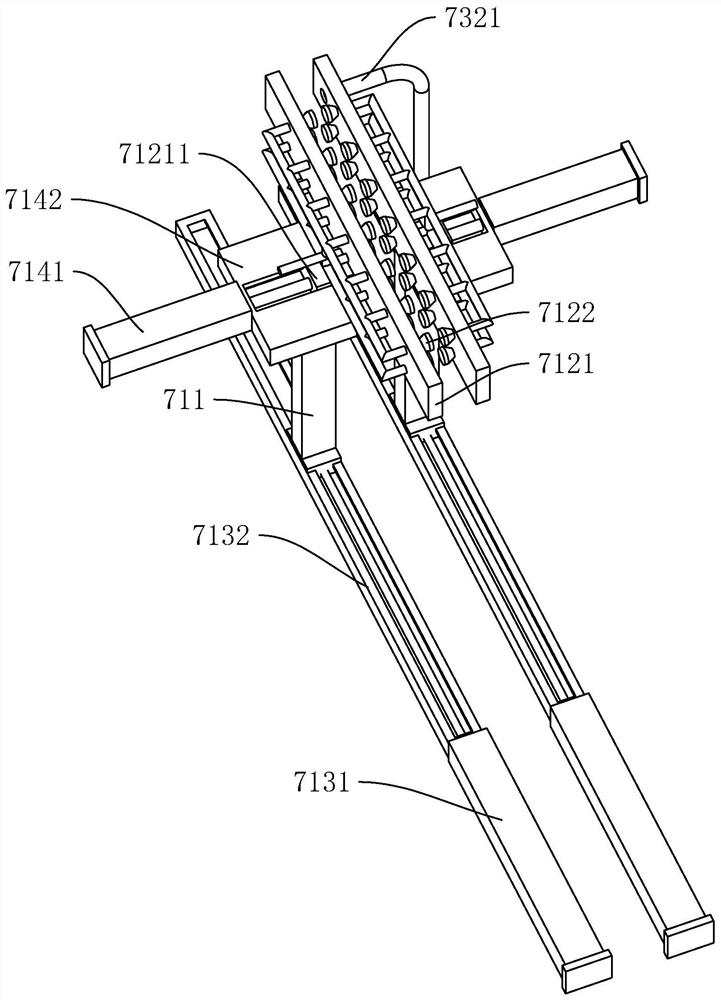

[0034] The embodiment of the present application discloses a hollow glass production line, referring to figure 1 , including a conveying device 1, and a feeding section 2, a cleaning chamber 3, a pasting section 4, a pressing chamber 5, and an unloading section 6 arranged sequentially on the conveying device 1 along the glass conveying direction. After the glass is placed on the feeding section 2, the conveying device 1 will drive the glass through the cleaning room 3, which cleans the glass and air-dries it, and then moves the glass to the pasting section 4. At this time, the aluminum frame and two pieces of glass need to be The two pieces of glass are pasted together, and the transmission device then transfers the two pieces of glass to the pressing room 5. The pressing room 5 presses the two pieces of glass to form an insulating glass, and then glues the edge of the insulating gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com