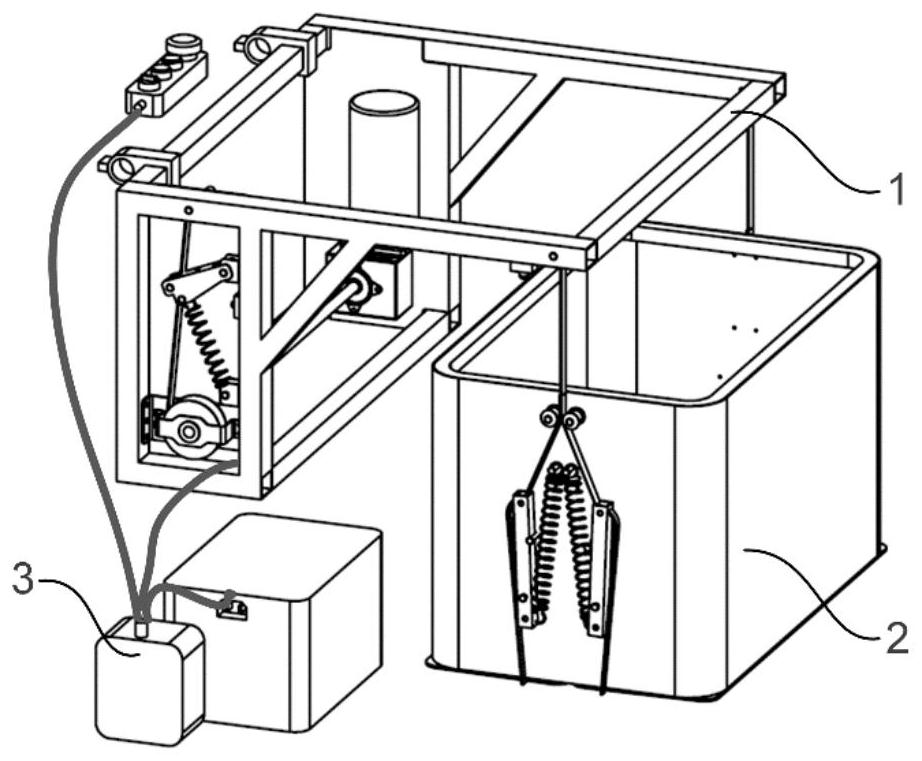

Material conveying device with automatic unloading function

A conveying device and automatic unloading technology, which is applied in the direction of lifting devices, lifting frames, picking machines, etc., can solve the problems of inconvenient fruit box transfer, reduced picking efficiency, and high center of gravity of vehicles, so as to reduce equipment operation time, improve safety factor, and reduce The effect of center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

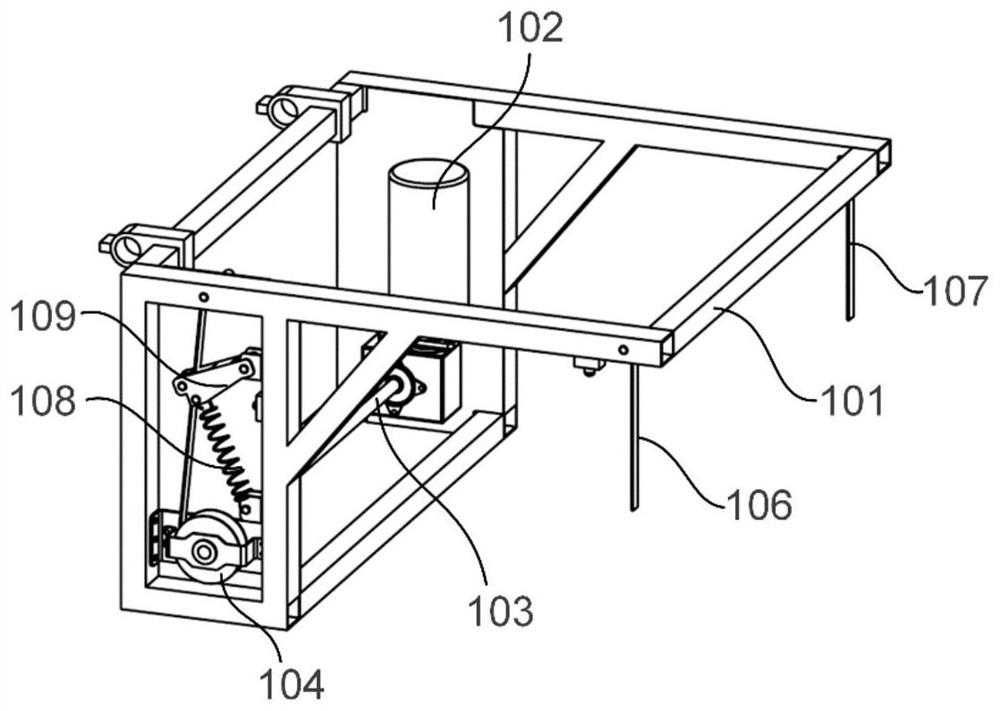

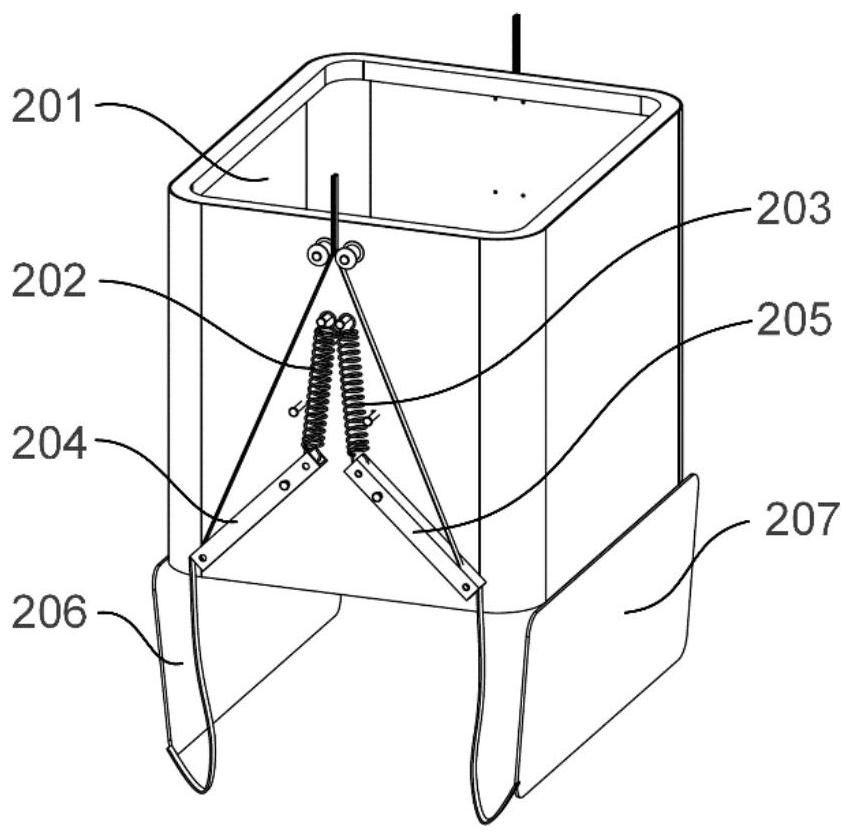

Embodiment Construction

[0030]In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions in the embodiments in the embodiments will be described in contemplation in the accompanying drawings in the embodiment of the present invention. Obviously, the described embodiments are the embodiments of the present invention, not all of the embodiments. The elements and features described in the drawings or one embodiment of the invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representations and descriptions of components and processes known to those of ordinary skill in the art, those of ordinary skill in the art, are omitted in the drawings, drawings and descriptions. Based on the embodiments in the present invention, those of ordinary skill in the art should belong to the scope of the present invention without the premise of creative labor.

[0031]The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com