Automatic paper receiving rack for pipe coiling machine

A coiling machine, an automatic technology, applied in the direction of coiling strips, cardboard products, thin material processing, etc., can solve the problems of complex structure, inconvenient installation, increased cost, etc., to reduce the operation process and shorten the duration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

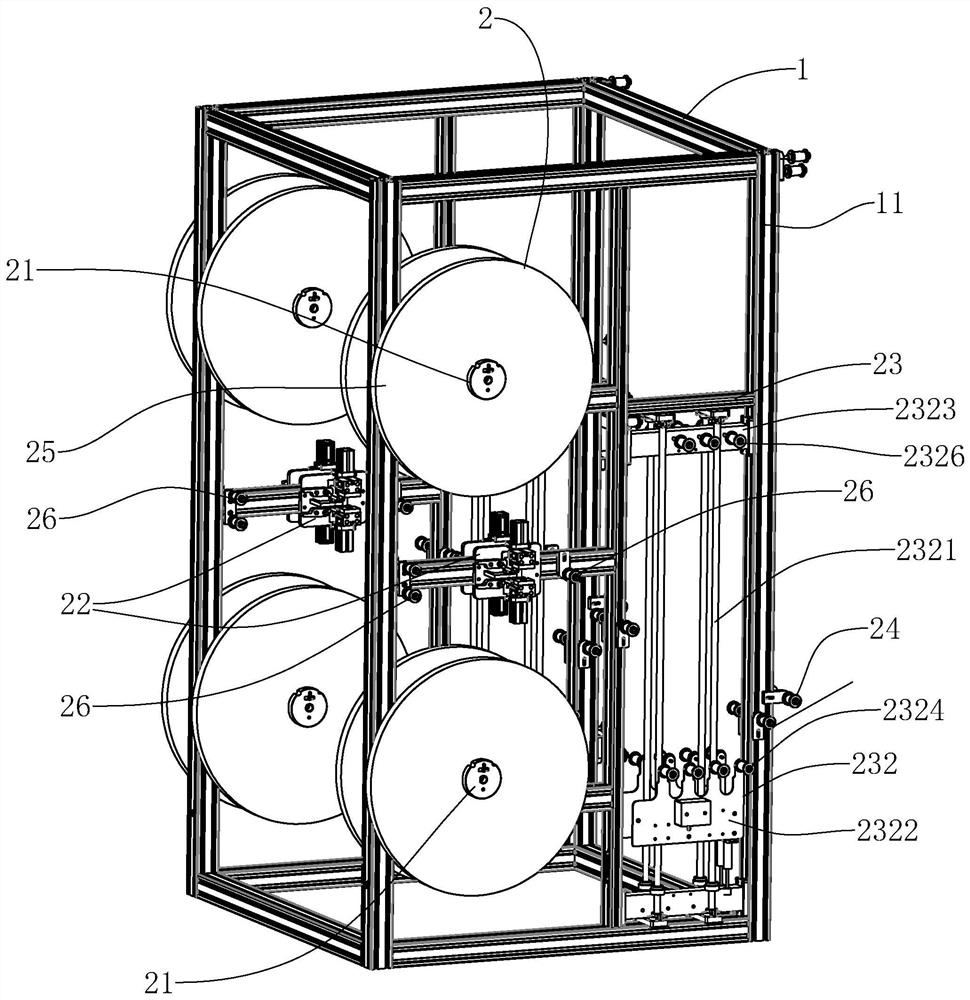

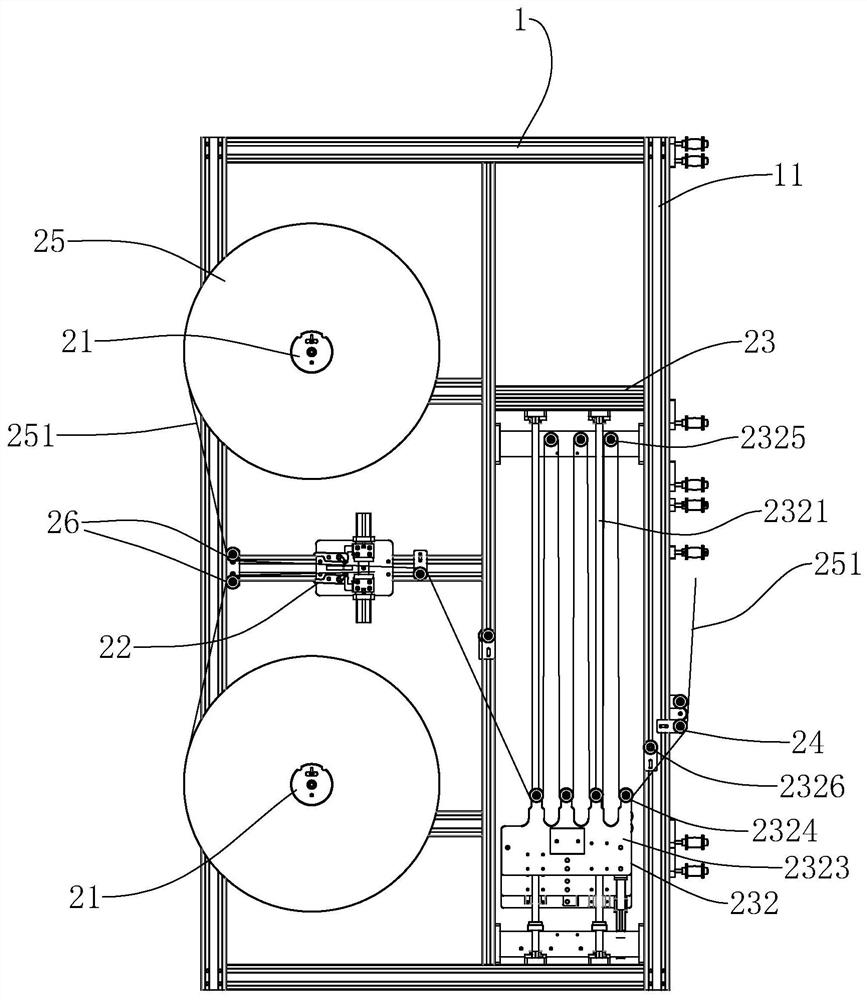

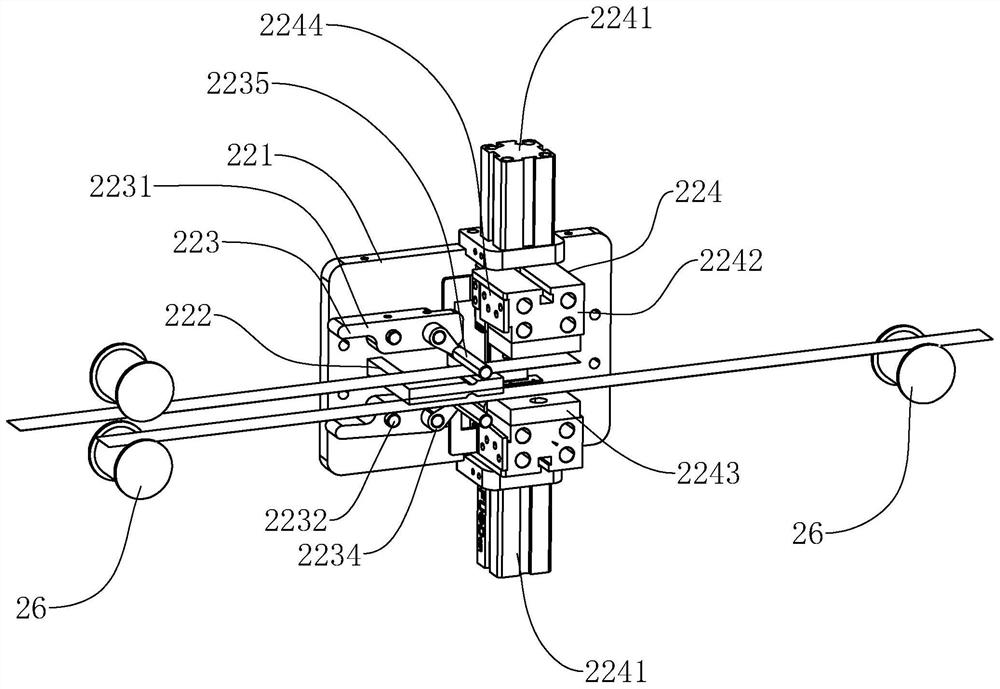

[0039] Such as Figure 1-4 As shown, the present invention is an automatic paper receiving rack for a coiling machine, including a mounting frame 1 and an automatic paper receiving device 2, the mounting frame 1 is arranged and fixedly connected by a plurality of mounting frames 11 in sequence, and the mounting frames 11 Both sides of each are provided with an automatic paper splicing device 2, the automatic paper splicing device 2 includes two paper tape brake discs 21, a paper splicing assembly 22, a paper tape storage buffer frame 23 and a discharge wheel 24, and the paper tape brake disc 21 is provided with a photoelectric sensor 211, the photoelectric sensor 211 is connected to the paper assembly 22; the paper tray 25 is arranged on the paper tape brake disc 21, and the two paper tape brake discs 21 are set up and down with the paper connection assembly 22 as the center line. A transition wheel 26 is provided between the belt brake disc 21 and the paper connecting assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com