Electromagnetic power device of fluid film suspension vehicle system

An electromagnetic power and fluid film technology, applied in electromechanical devices, sliding/floating railway systems, magnetic attraction or thrust holding devices, etc., can solve the problem of limiting the speed and efficiency of linear motor wheel-rail traffic trains, bogies and wheels For problems such as not having a streamlined structure and being difficult to overcome air resistance, it can achieve the effect of improving electromagnetic conversion efficiency, reducing electromagnetic coupling gap, and solving large air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

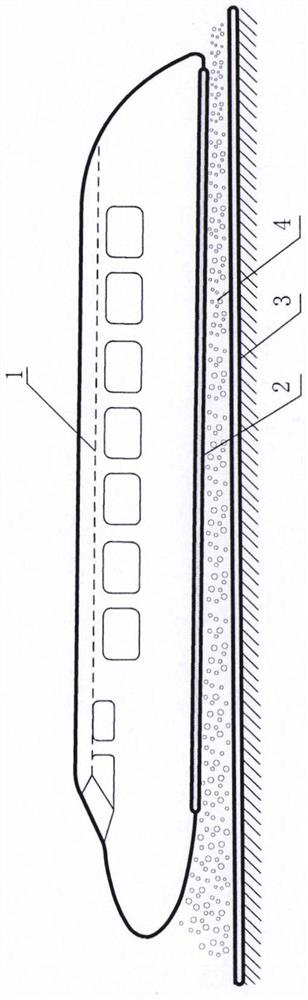

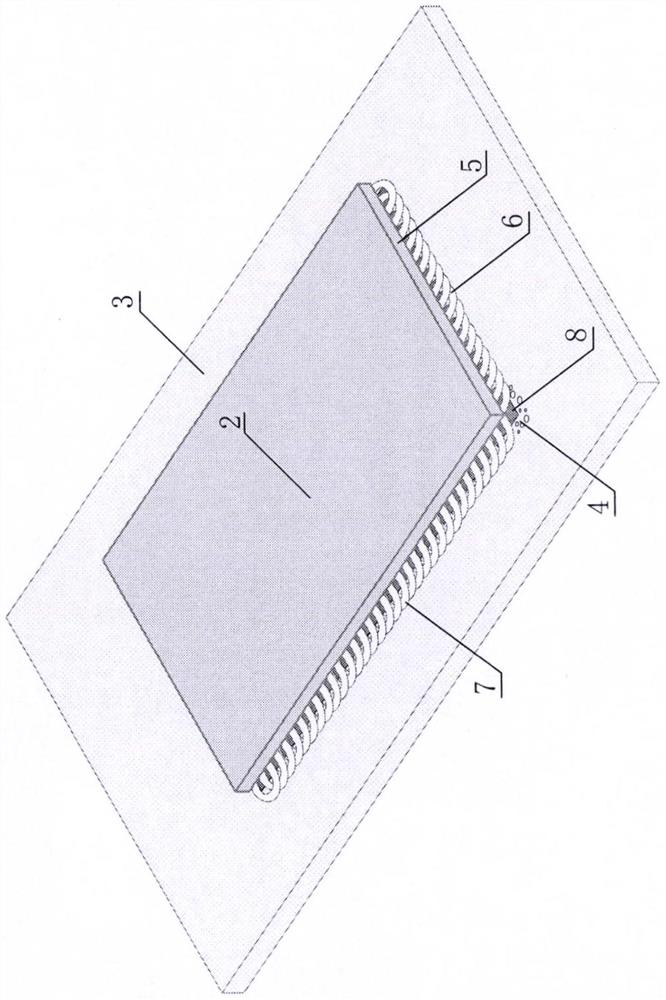

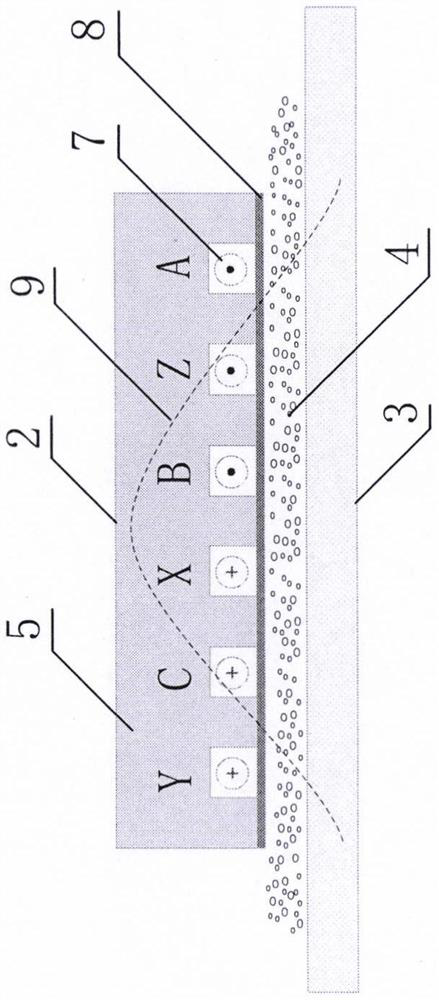

[0034] Combine below Figure 1 to Figure 5 Describe the present embodiment, the embodiment of the fluid film levitation vehicle electromagnetic power device of the present invention comprises: compartment 1, primary 2, secondary 3, electromagnetic coupling gap (fluid film) 4, primary magnetic conduction layer 5, primary longitudinal winding 6 , primary transverse winding 7, primary surface layer 8, traveling magnetic field 9, etc. The basic idea of the present invention is to install the primary 2 and the secondary 3 on the wide chassis surface and track surface of the fluid film suspension vehicle to increase the electromagnetic coupling area, and use the thinner pressure fluid film 4 as the electromagnetic coupling gap to reduce the electromagnetic coupling The size of the gap, the electromagnetic power device of the fluid film levitation vehicle of the present invention can significantly improve the electromagnetic power, electromagnetic conversion efficiency and power fa...

specific Embodiment approach 2

[0041] The electromagnetic power device of the present invention has a smaller electromagnetic coupling gap and a larger electromagnetic coupling area, which promotes the diversification of motor forms. This embodiment is a supplement to the diversification of motor forms in Embodiment 1. Combine below Figure 6 to Figure 10 The embodiment of the present invention will be further described.

[0042] When the primary 2 is installed on the train chassis and the secondary 3 is installed on the track surface, a short primary motor form is formed, mainly including: short primary induction motor, short primary switched reluctance motor, short primary synchronous motor, short primary double-fed motor etc.

[0043] The secondary 3 of the short primary induction motor can be a solid conductor structure, as in Embodiment 1 image 3 As shown, the construction cost of this secondary structure is the lowest; the secondary 3 of a short primary induction motor can also be as Image 6 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com