Digital ink-jet printer

A technology of digital inkjet and printer, applied in printing devices, printing and other directions, can solve the problems of waste, printing, repairing and printing of handwriting that cannot be blurred, etc., and achieve the effect of repairing blurred images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

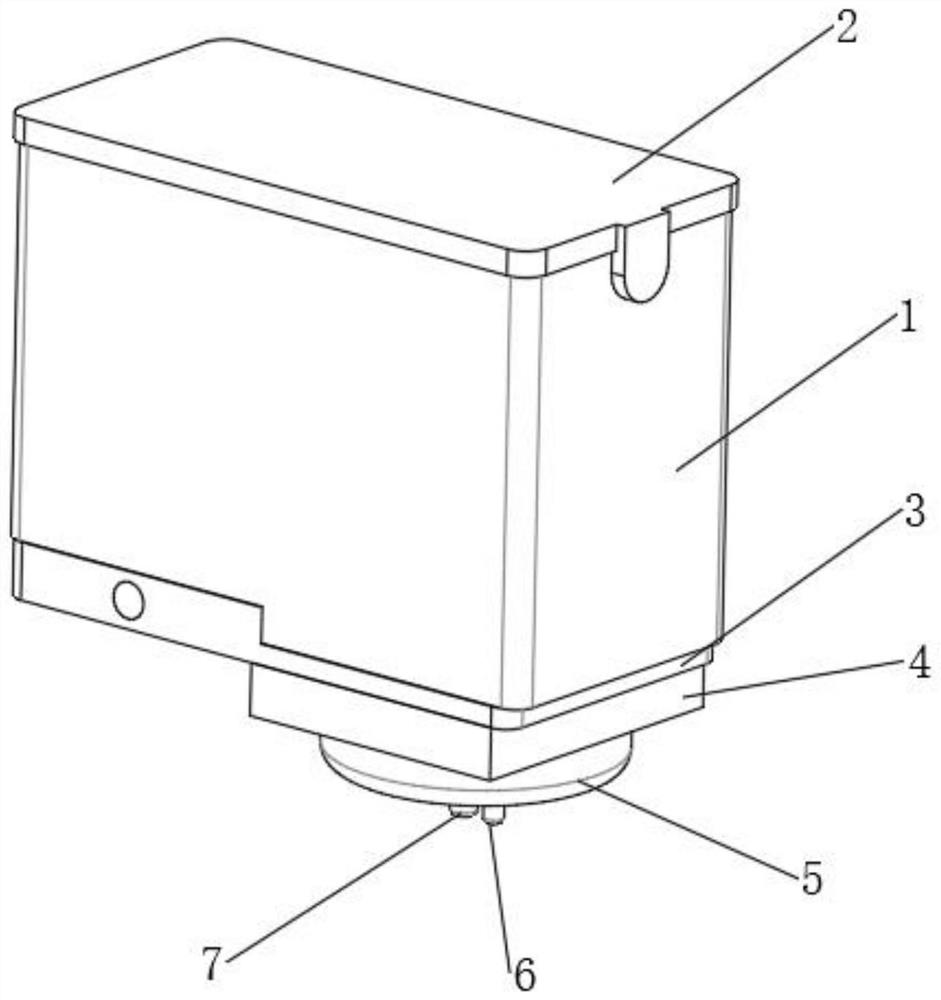

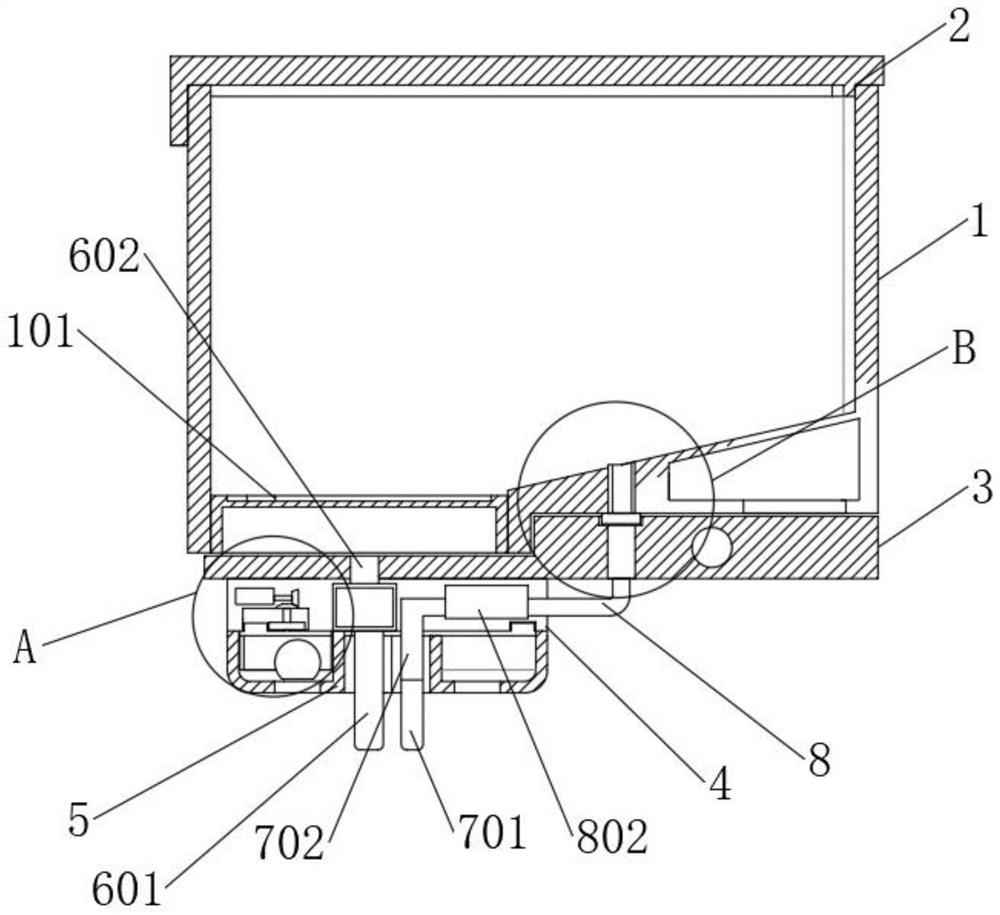

[0036] see Figure 1-5 , a digital inkjet printer, comprising a printer main body, an ink cartridge main body 1 is installed in the printer main body, a sealing cover 2 is clamped on the ink cartridge main body 1, a mounting plate 3 is clamped on the lower end of the ink cartridge main body 1, and the mounting plate 3 is fixedly connected There is an intubation tube, the bottom end of the ink cartridge main body 1 is drilled with a slot matching the intubation tube, the bottom end of the mounting plate 3 is fixedly connected with the lower support 4, and the lower end of the lower support 4 is fixedly connected with the detection table 5, and the lower support A controller is installed in the seat 4, and the bottom end of the inner wall of the ink cartridge main body 1 is fixedly connected with a bracket 101, and a filter screen is laid on the bracket 101.

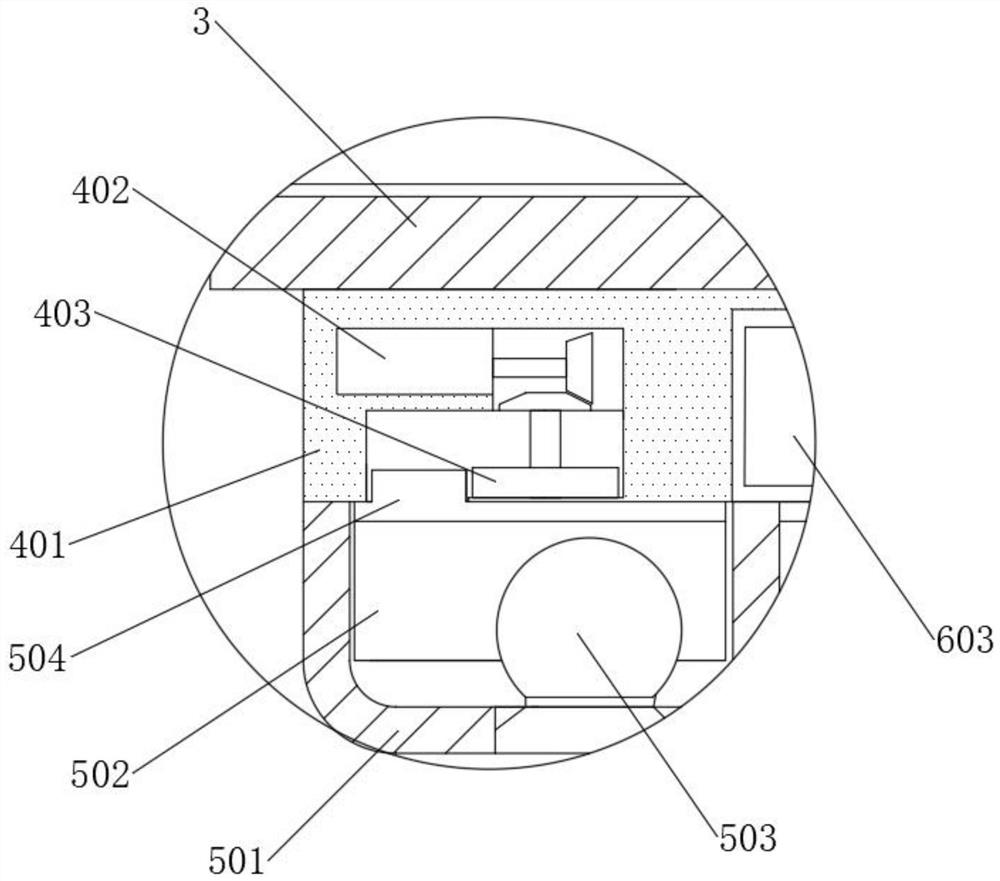

[0037] see Figure 1-4 The lower support 4 includes a housing 401. A stepping motor 402 is installed in the housing 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com