Lithium battery recovery process

A lithium battery and process technology, applied in the field of lithium battery recycling technology, can solve problems such as affecting recycling efficiency, explosion, incomplete discharge, etc., and achieve the effects of improving treatment effect, reducing air leakage rate, and improving screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

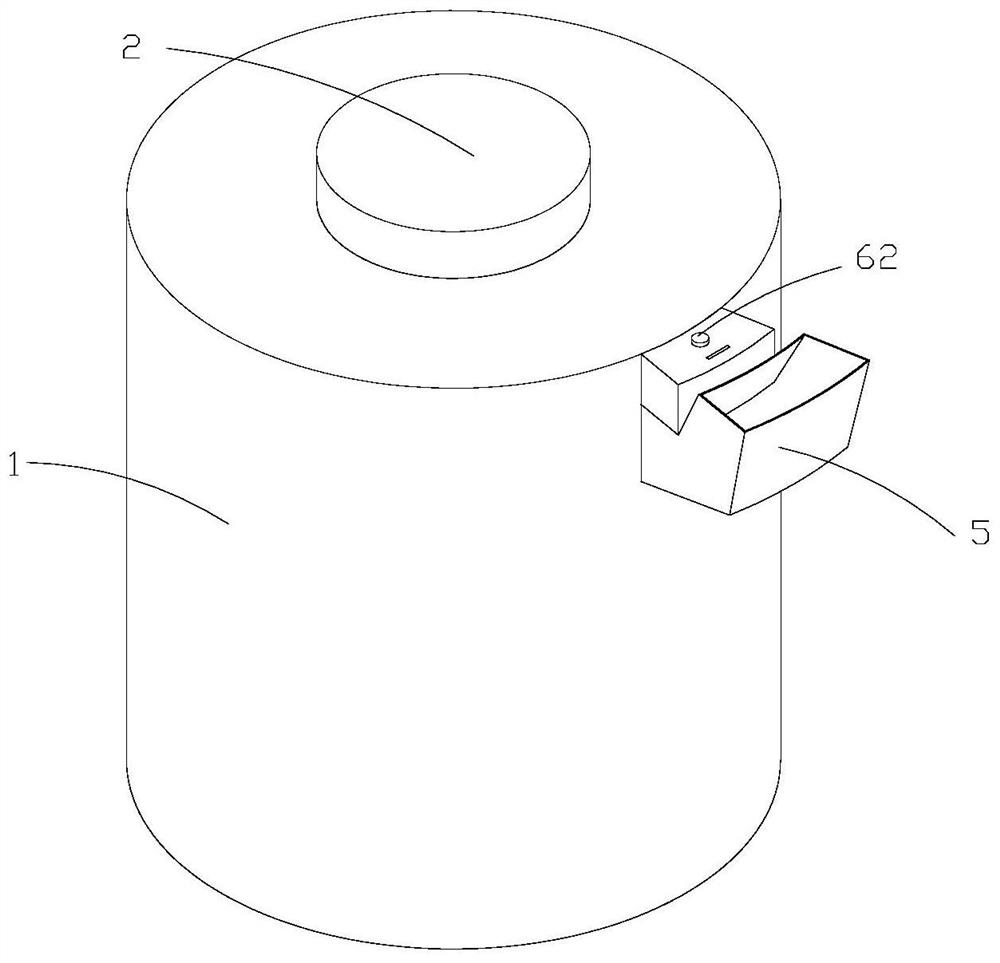

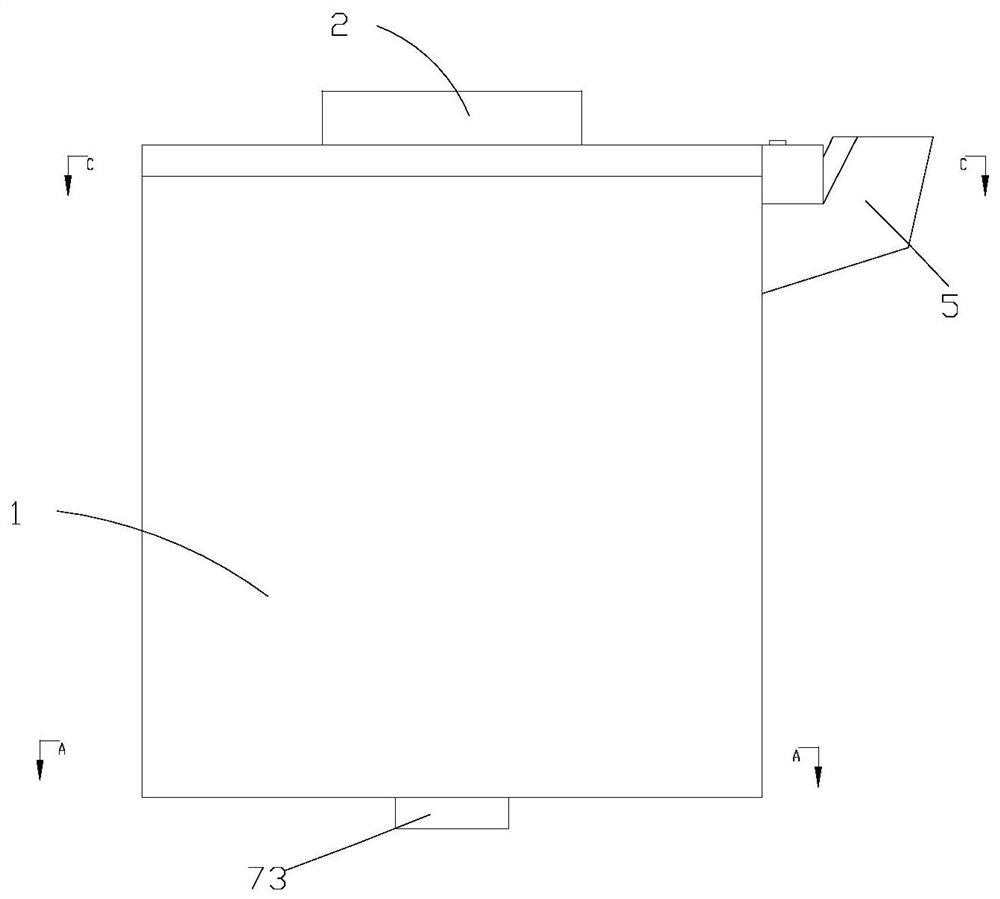

[0036] Such as Figure 1-13 Shown, a kind of lithium battery recycling process comprises the following steps:

[0037] a. First discharge the lithium battery;

[0038] b. Dismantling the lithium battery after discharge treatment in a, and recycling the disassembled shell;

[0039] c. Discharge the internal electrolyte of the disassembled lithium battery in b;

[0040] d. Send the lithium battery discharged from the electrolyte in c to the sorting and recycling device for crushing and recycling;

[0041] Wherein, the recovery device described in the step d includes a main body 1, a first motor 2, a rotating plate 3, a crushing device 4, a feed port 5, a sealing device 6, and a sorting device 7; the crushing device 4 includes a U-shaped groove 41. Rack 42, moving block 43, gear 44, rotating roller 45, filter plate 46, crushing knife 47, driving mechanism 8; the cross section of the main body 1 is circular; the first motor 2 is arranged on the main body 1, which is purchased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com