Automatic production line system and method for detecting size and surface defects of medium-sized cross shaft

A technology for automated production lines and defect detection. It is applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

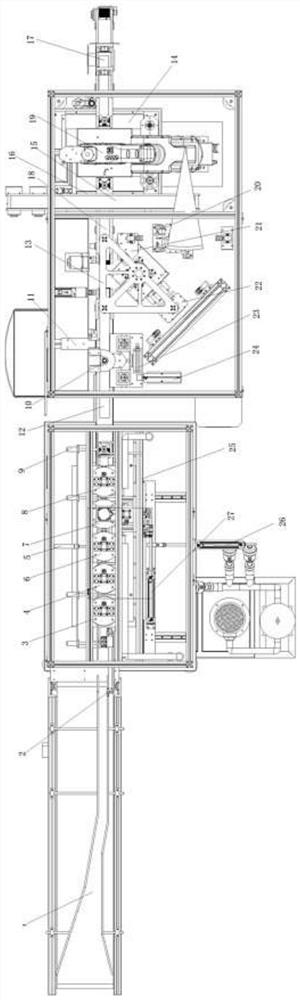

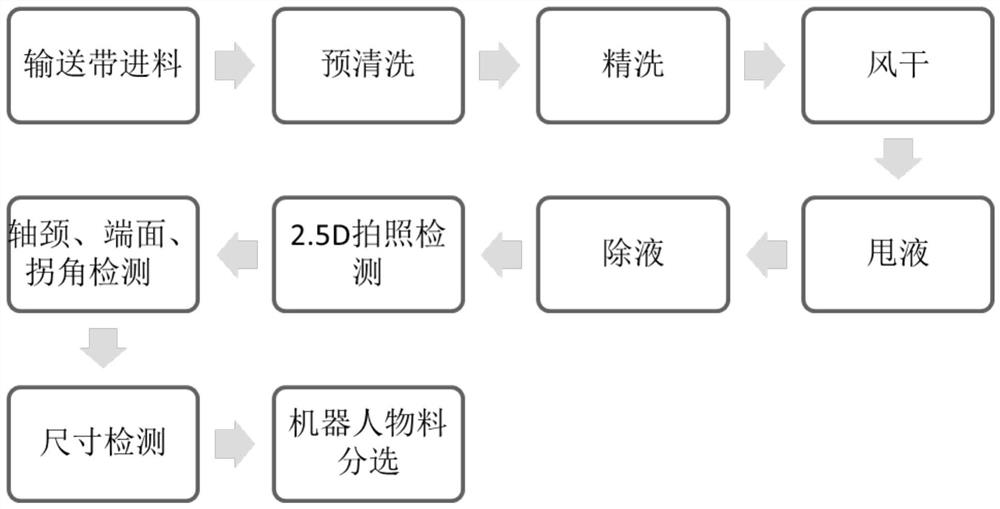

[0045]Example 1, in the present invention, the workpiece (cross shaft) moves from left to right and accepted various steps such as cleaning, air drying, detection, and classification, will be set from left to the right horizontal direction; medium-type cross shaft size and Automated production line system for surface defect detection, such asfigure 1 , Includes feed mechanisms, cleaning drying mechanism, 2.5d camera detecting mechanism, machine visual detection mechanism, and product sorting mechanism, machine visual detection mechanism, and product sorting mechanism, and machine visual detection mechanism, and product sorting mechanism, and the control system 40 and The above mechanisms are connected to control the operation of each mechanism.

[0046]The feed mechanism includes a feed conveyance belt 1 and a feed gripping device 2, a feed conveyor belt 1 laterally, adjacent to the front end with a cross-axle processing line, and the feed grab device 2 is disposed in feed delivery. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com