Ejector capable of cooling valve core needle through cooling working medium

A technology for cooling working fluid and ejector, applied in the direction of jet pump, jet device, liquid jet device, etc., can solve problems such as motor damage, achieve the effect of simple structure, increase the scope of application of working conditions, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

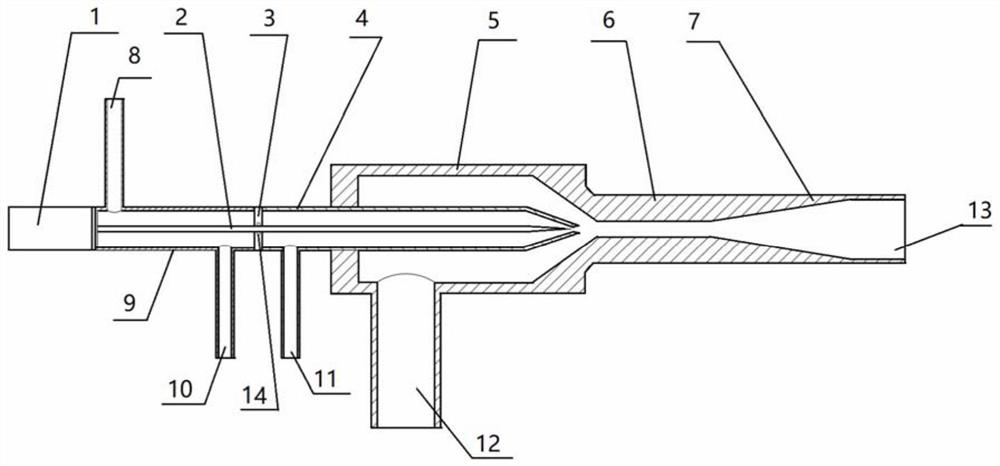

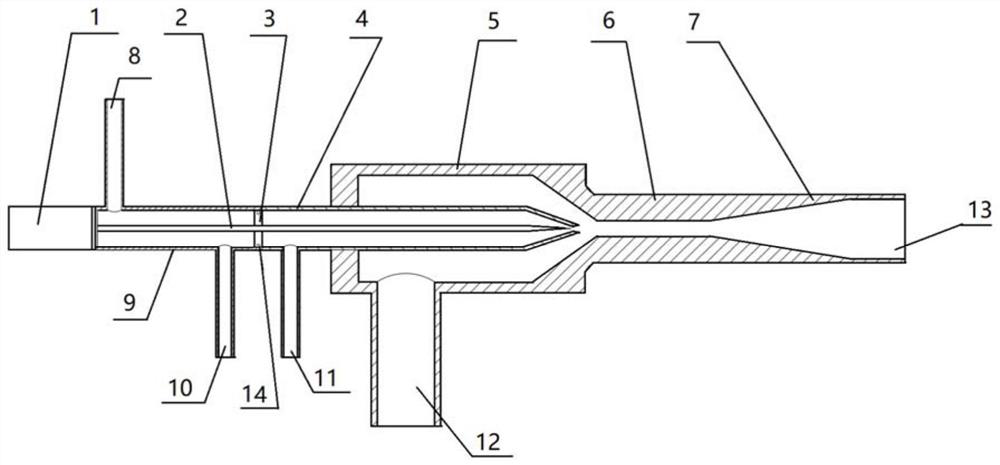

[0011] The injector proposed by the present invention utilizes the cooling working fluid to cool the spool needle, and its structure is as follows: figure 1 As shown, it includes stepper motor 1, cooling section 9, nozzle 4, secondary flow suction chamber 5 and spool needle 2; the stepping motor 1, cooling section 9, nozzle 4 and secondary flow suction chamber 5 are the same Shaft installation, a sealing element 3 is provided between the cooling section 9 and the nozzle 4, the valve core needle 2 is placed on the central axis of the cooling section 9 and the nozzle 4, and the valve core needle 2 passes through the middle hole of the sealing element 3 After that, the output shaft of the stepping motor 1 is linked with the spool needle 2; the nozzle 4 is inserted into the secondary flow suction chamber 5; the cooling section 9 is provided with a cooling medium inlet 8 and a cooling medium outlet 10 One end of the nozzle 4 close to the sealing element 3 is provided with a primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com