Spray ring with adjustable nozzle angle and air-assisted sprayer

A spray ring and nozzle technology, which is used in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of inability to realize real-time adjustment of airflow and mist flow, fixed angle, etc., and achieve a control method with less energy consumption, The effect of precise governance and various adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

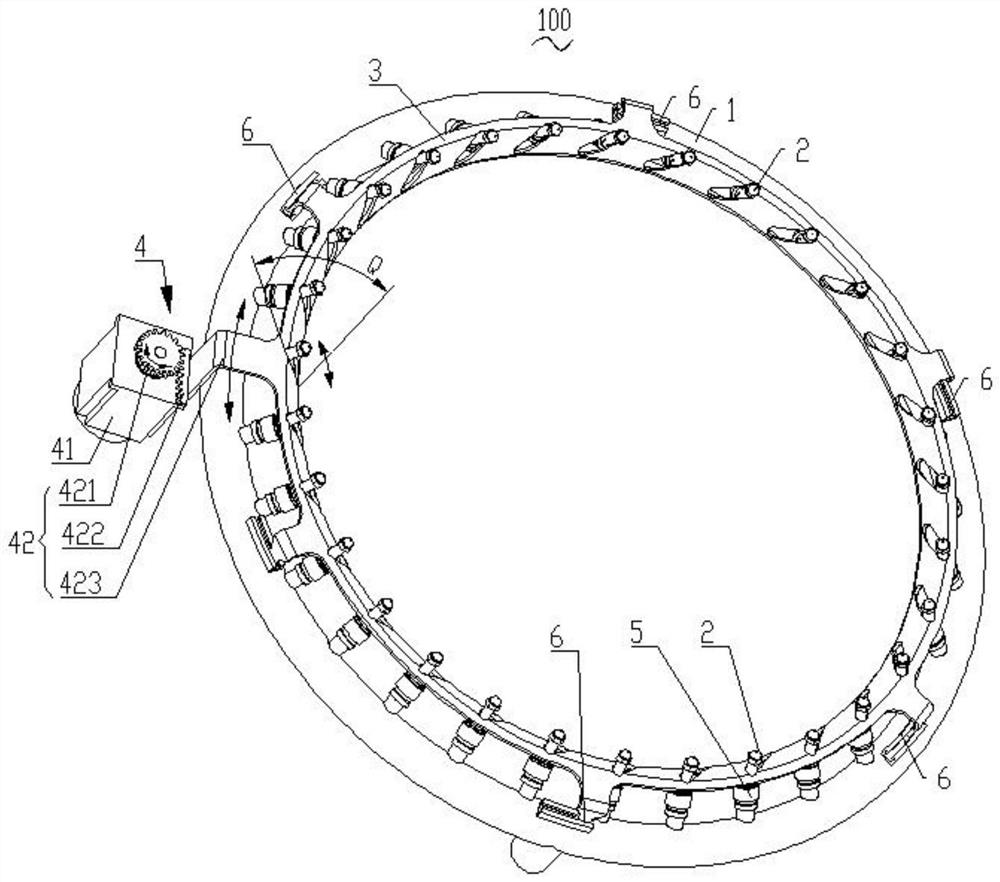

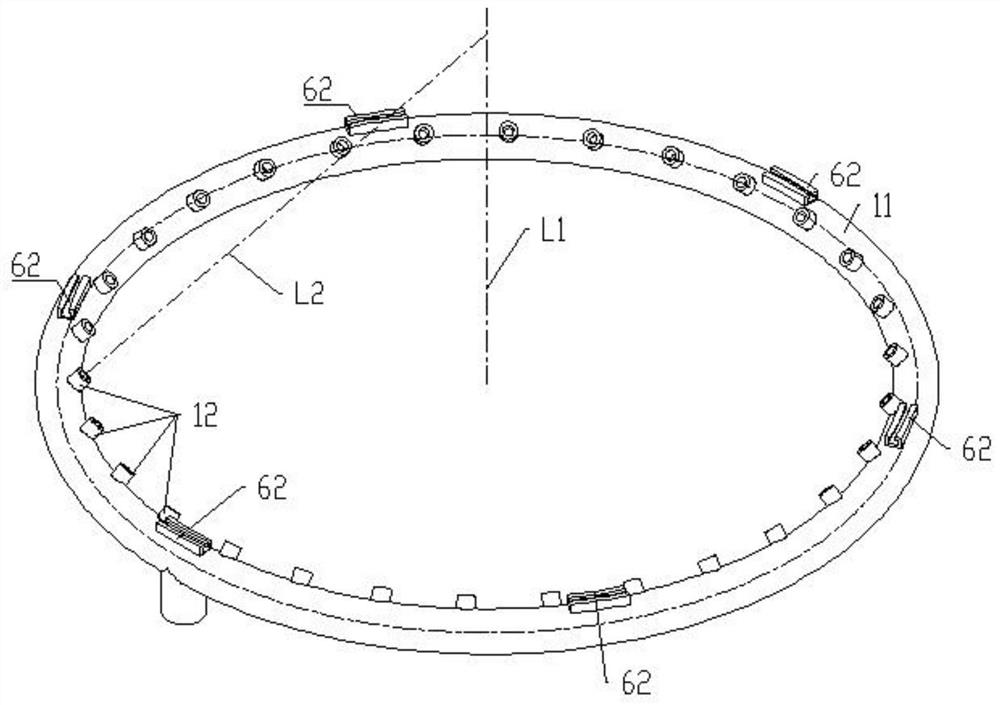

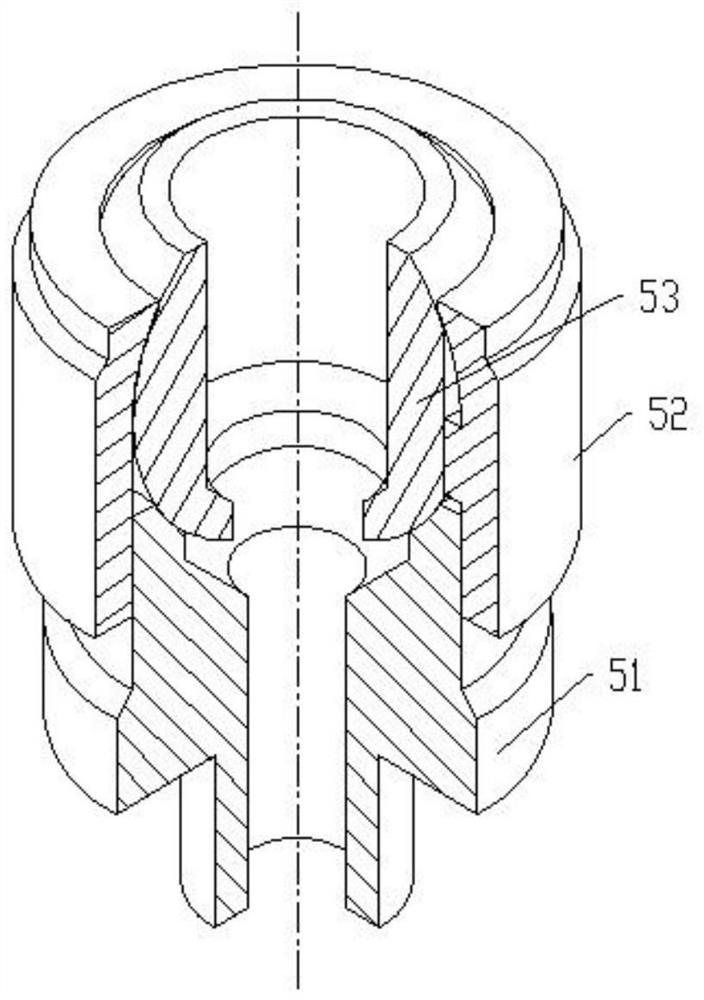

[0041] Reference attached Figure 1-6 , figure 1 The direction indicated by the arrow in the center is the moving direction of each component. Image 6 The direction indicated by the middle arrow is the height direction of the adjustment frame 3, a spray ring 100 with adjustable nozzle angle, including: spray ring pipe 1, nozzle 2, adjustment frame 3 and adjustment power part 4, the spray ring pipe 1 as a whole is Annular tubular, the adjustment frame 3 is provided with a waist-shaped groove 31 running through it, the angle between the extension direction of the waist-shaped groove 31 and the height direction of the adjustment frame 3 is Q, 0° Figure 9 , the nozzle 2 runs through the waist-shaped groove 31, and one end of the nozzle 2 is connected to the spray ring pipe 1 by a ball hinge, the adjustment frame 3 is slidingly connected with the spray ring pipe 1, and the adjustment power part 4 is used to drive the adjustment frame 3 along the spray ring The tube 1 slides back ...

Embodiment 2

[0052] Please focus on reference Image 6 , Image 6 The direction indicated by the middle arrow is the height direction of the adjustment frame 3 , and the arrow direction is also the telescopic direction of the linear power actuator 43 . A spray ring 100 with an adjustable nozzle angle, comprising: a spray ring pipe 1, a nozzle 2, an adjustment frame 3 and an adjustment power part 4. Shaped groove 31, the angle between the extending direction of the waist-shaped groove 31 and the height direction of the adjustment frame 3 is Q, 0°<Q<90°, the nozzle 2 runs through the waist-shaped groove 31, and one end of the nozzle 2 is connected to the spray ring pipe 1 They are connected by ball hinges, the adjustment frame 3 is slidingly connected with the spray ring pipe 1, and the adjustment power part 4 is used to drive the adjustment frame 3 to slide back and forth along the spray ring pipe 1 to change the angle of the nozzle 2. The adjusting power member 4 is a linear power actuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com