Sludge collecting equipment

A technology for collecting equipment and sludge, applied in the field of equipment in sludge collection companies, can solve the problems of low sludge water removal effect, odor generation, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

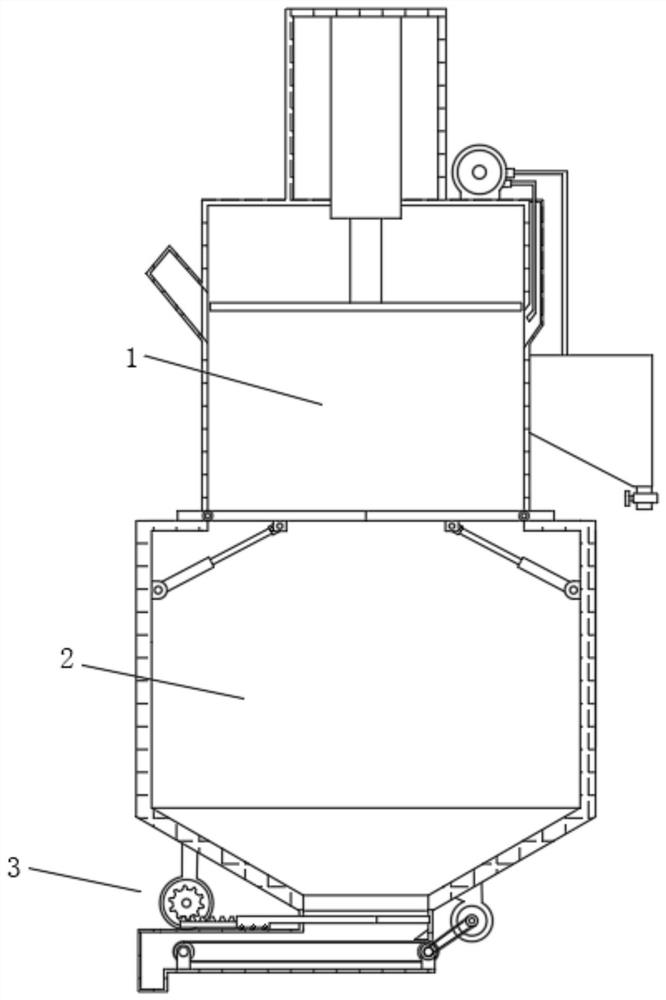

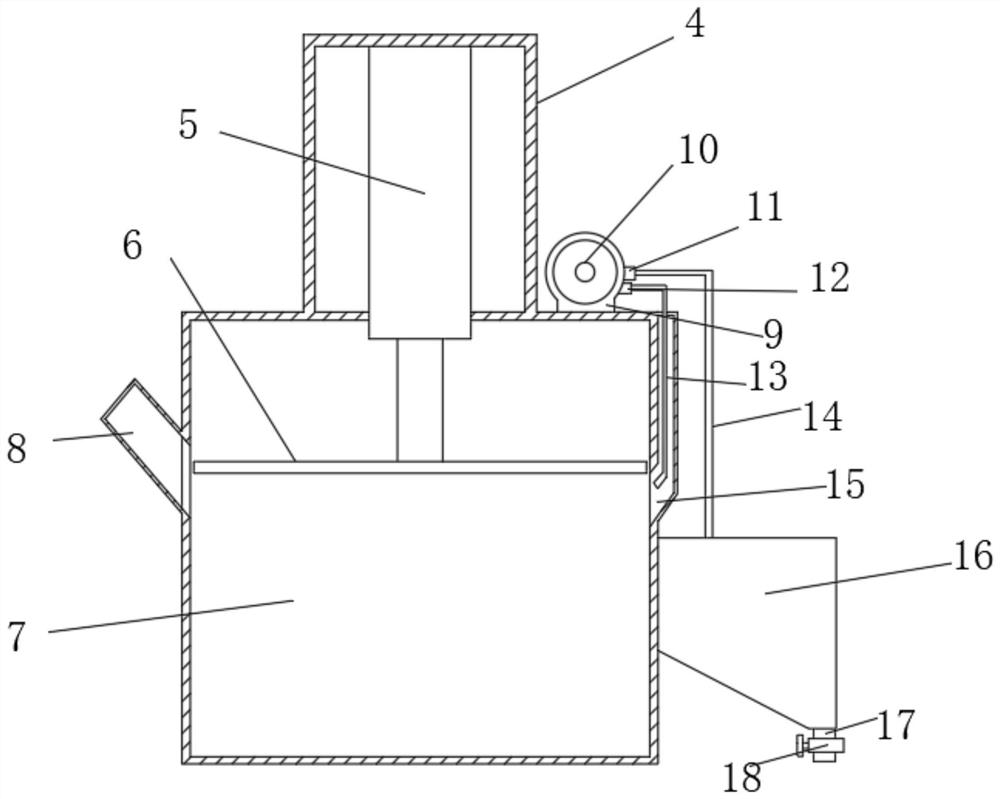

[0022] A kind of sludge collection equipment, in order to solve the problem that sludge carries out secondary pollution to the environment, as a preferred embodiment, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a static compression chamber 1, a material storage chamber 2 and a transport device 3. The static compression chamber 1 includes a compression chamber 4 and a static chamber 7. The interior of the compression chamber 4 is provided with a hydraulic rod 5, and one end of the hydraulic rod 5 The pressure plate 6 is fixedly connected, the side of the static chamber 7 is provided with a feed port 8 and a pipe chamber 15, one side of the static chamber 7 is fixedly installed with a sewage tank 16, and the top of the static chamber 7 is provided with a water pump fixing frame 9. A water pump 10 is provided inside the water pump fixing frame 9. One end of the water pump 10 is provided with a water suction port 12 and a water outlet 11. The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com