Rocker arm structure of short-body coal mining machine with wide mining range

A coal mining machine and a range of technology, applied to components with teeth, mechanical equipment, earthwork drilling and mining, etc., can solve the problem that the rocker arm has a large force, is not suitable for mining with thin coal seam height, and affects the force of the boom support Point connection reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

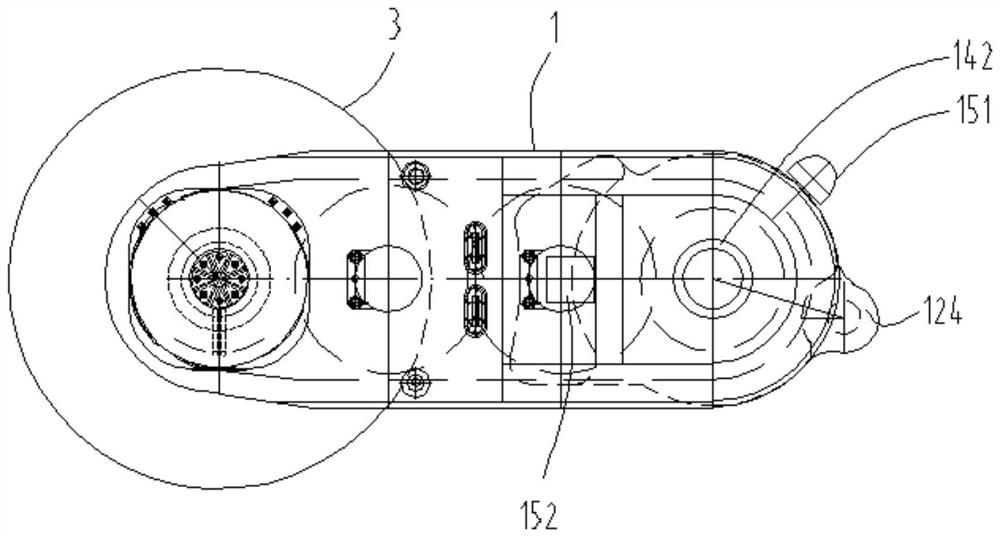

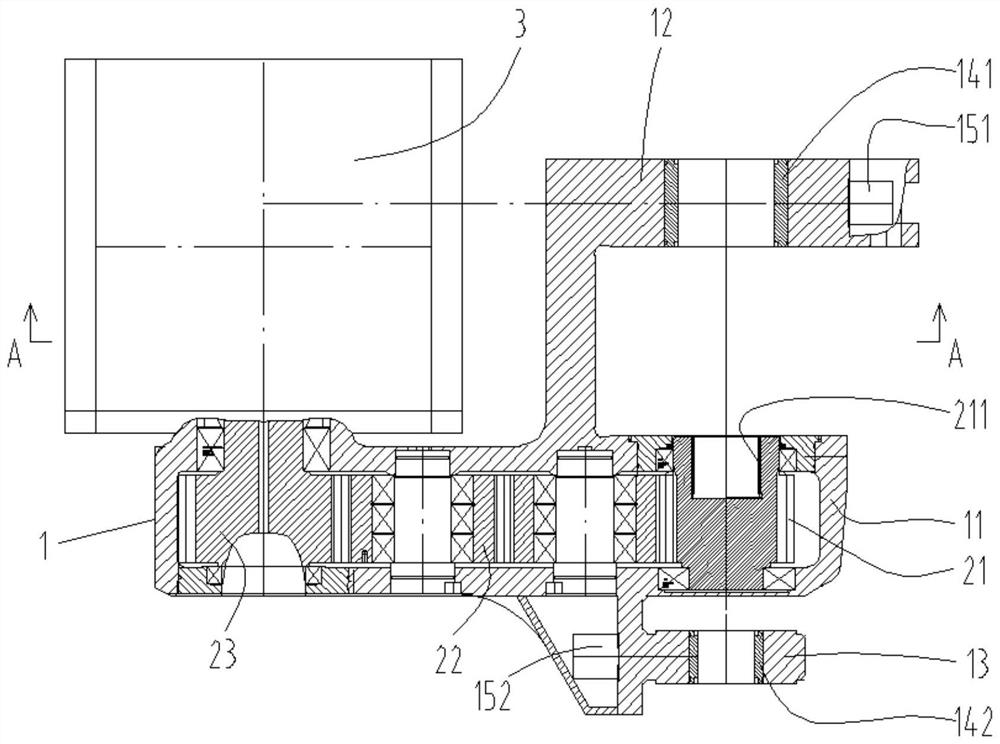

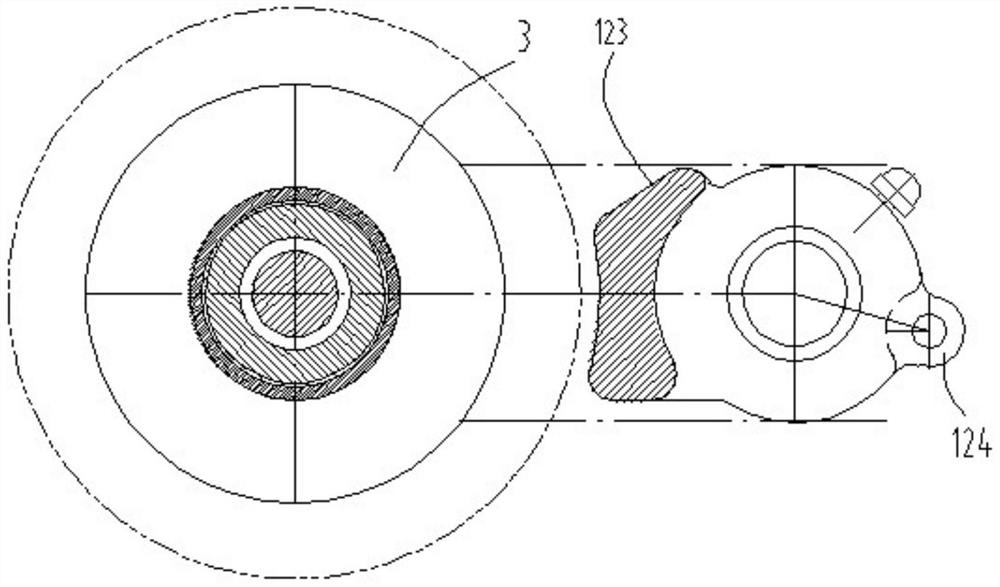

[0030] The invention discloses a rocker arm structure (which can be referred to simply as the rocker arm structure) of a low-body shearer with a wide mining range, such as Figure 1-5 As shown, the boom housing 1 is included, and the boom housing includes an L-shaped transmission box 11, and the free ends of the left and right extensions of the transmission box (corresponding to figure 2 The right end of the middle transmission box 11) is provided with a transmission input interface structure, and the front end (that is, the end close to the coal wall side) of the front and rear extensions of the transmission box is provided with a transmission output interface structure, the transmission input interface structure and the transmission output interface The structures are respectively used to connect with the front-stage cutting transmission mechanism and the drum. A front support arm 12 and a rear support arm 13 are respectively provided at the front and rear of the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com