Dry-type connecting outer wall structure system and mounting method thereof

A system and exterior wall technology, applied to walls, building components, building structures, etc., can solve problems such as time-consuming, high risk of water seepage in exterior walls, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

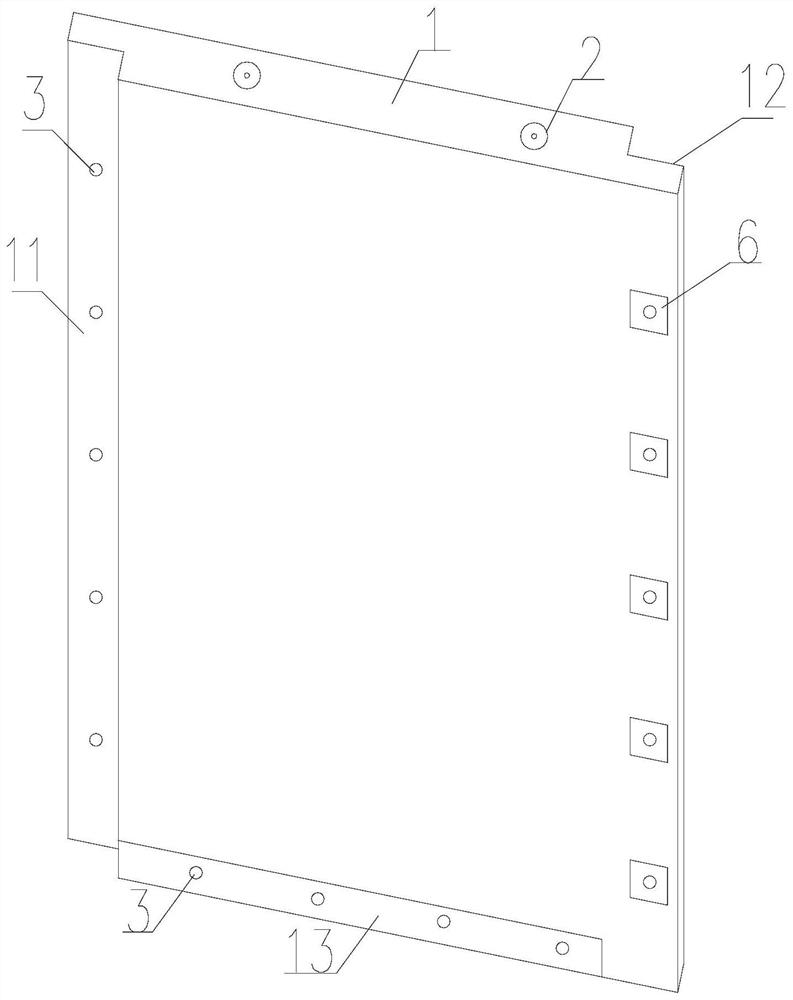

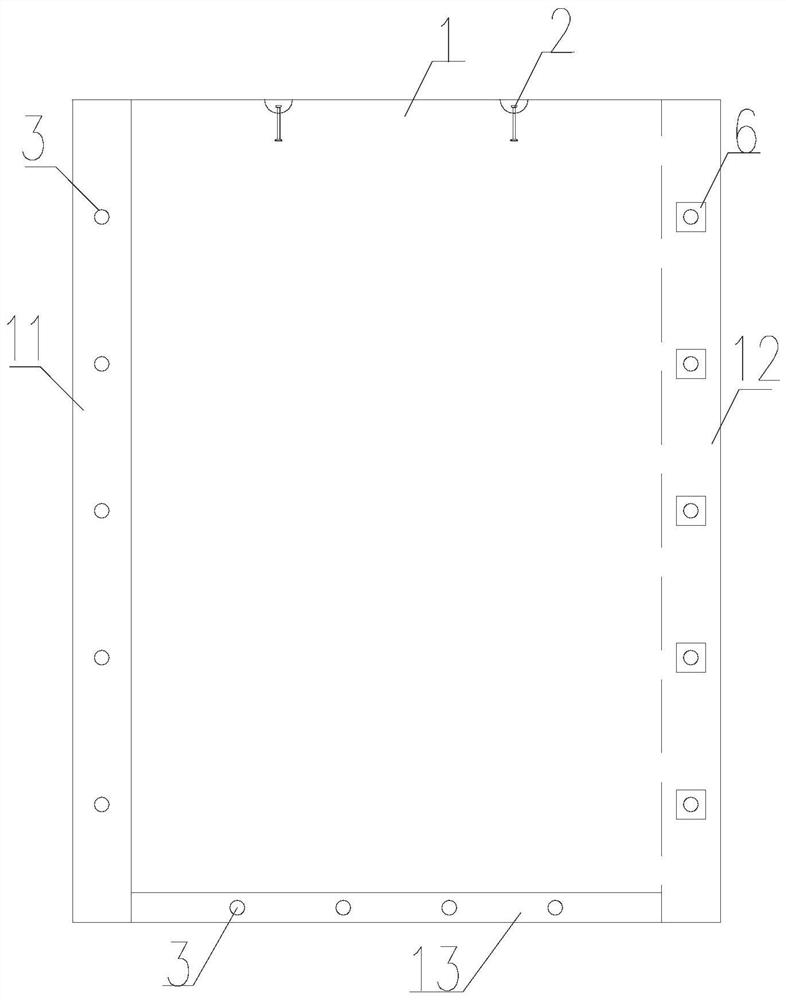

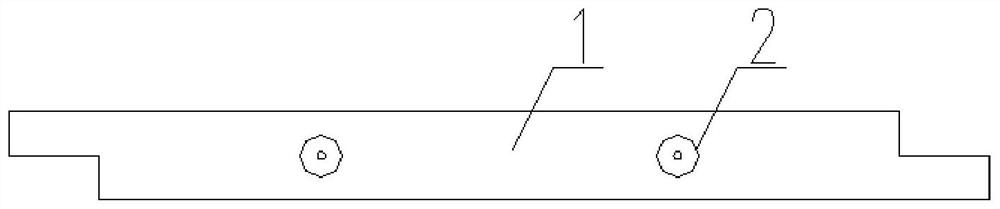

[0047] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

[0048] A dry-connected exterior wall structural system such as Figure 8 As shown, a plurality of prefabricated exterior wall panels 1 are included. Two adjacent outer wall panels 1 on the left and right are connected by bolts. The top of the exterior wall panel 1 needs to be connected with the floor slab by cast-in-place, and the bottom of the exterior wall panel 1 is connected by bolts and steel plates.

[0049] In this embodiment, the main material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com