Winding system for cable distribution and winding process

A cable and wiring technology, which is applied in the winding system and winding process of cable wiring, can solve the problems of separation of two cables, loose winding of copper core, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

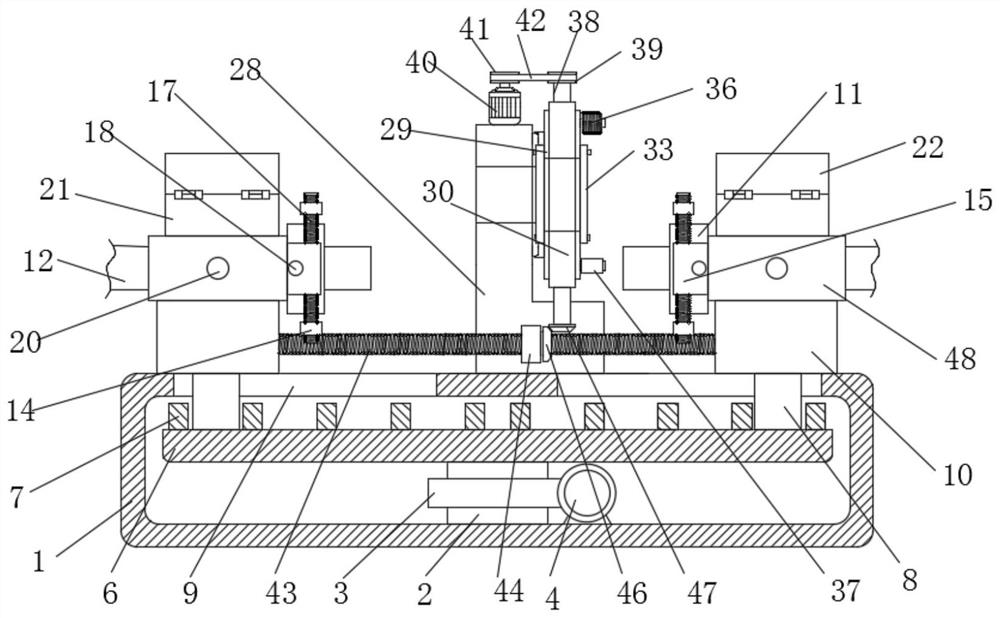

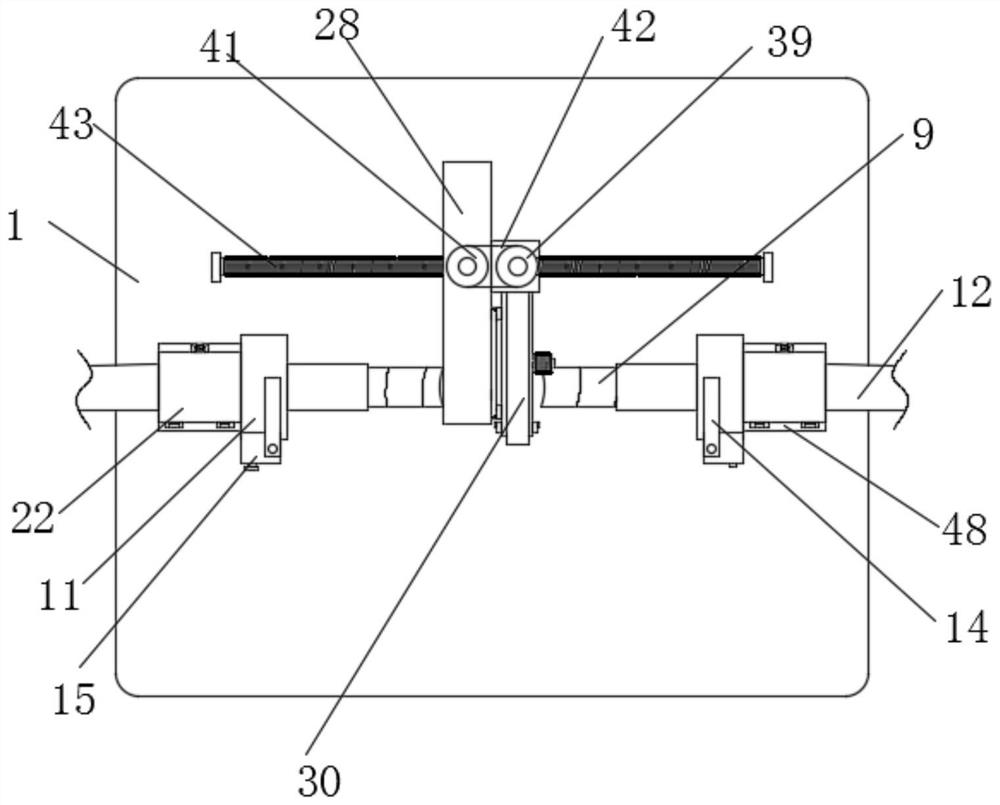

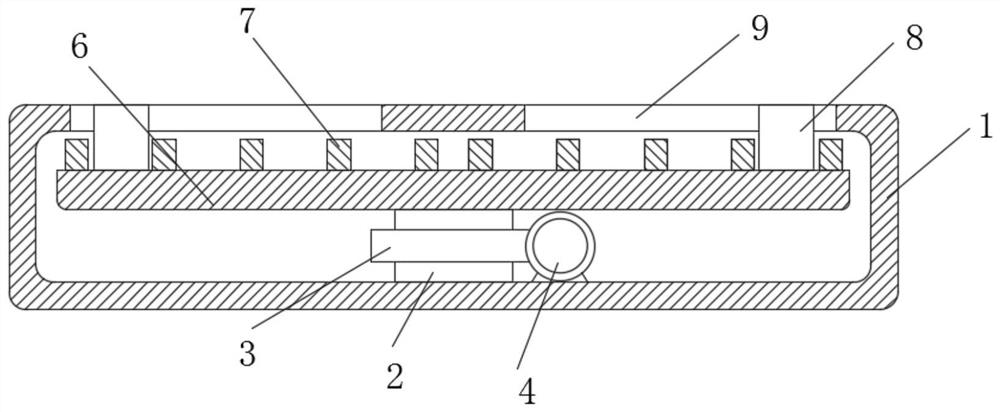

[0049] refer to Figure 1-14 , a winding system for cable wiring, including a workbench 1, the top of the workbench 1 is slidably connected with two symmetrical support blocks 10, and the workbench 1 is provided with a mechanism for sliding the two support blocks 10 to each other. The sliding assembly, the tops of the two support blocks 10 are fixedly connected with a placement tube 48, the two placement tubes 48 are provided with cables 12, and the ends of the two placement tubes 48 that are close to each other are rotatably connected with a turntable 11, and the placement tube 48 A stripping assembly for stripping the insulation layer of the cable 12 is provided on one side, the tops of the two placement cylinders 48 are fixedly connected with the lower clamping block 21, and one side of the two lower clamping blocks 21 is provided with a fixing assembly for fixing the cable 12 , the top of the workbench 1 is slidably connected with a sliding frame 28, one side of the slidin...

Embodiment 2

[0064] Embodiment two: if Figure 15 As shown, a winding system for cable wiring, the difference between this embodiment and Embodiment 1 is that: the top of the workbench 1 is slidably connected to a sliding plate 50, and the top of the sliding plate 50 is rotatably connected to a rotating rod 51, which rotates Both ends of the bar 51 are fixedly connected with a gear 56, and the gear 56 and the ring gear 49 are meshed. The outer wall of the rotating bar 51 is fixedly sleeved with a second sprocket 54, and the top of the sliding plate 50 is fixedly connected with a stepping motor 52. The output shaft of the feeder motor 52 is fixedly connected with a first sprocket 53 , and the outer walls of the first sprocket 53 and the second sprocket 54 are connected with the same chain 55 for transmission.

[0065] However, as is well known to those skilled in the art, the working principles and wiring methods of the driving motor 4, the rotating motor 40, and the stepping motor 52 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com