Dust treatment device for reprocessed plastic particle processing workshop

A technology for recycling plastic particles and dust treatment, which is applied in the directions of packaging, transportation and packaging, and separation of dispersed particles, and can solve problems affecting the health of workers and the environment of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

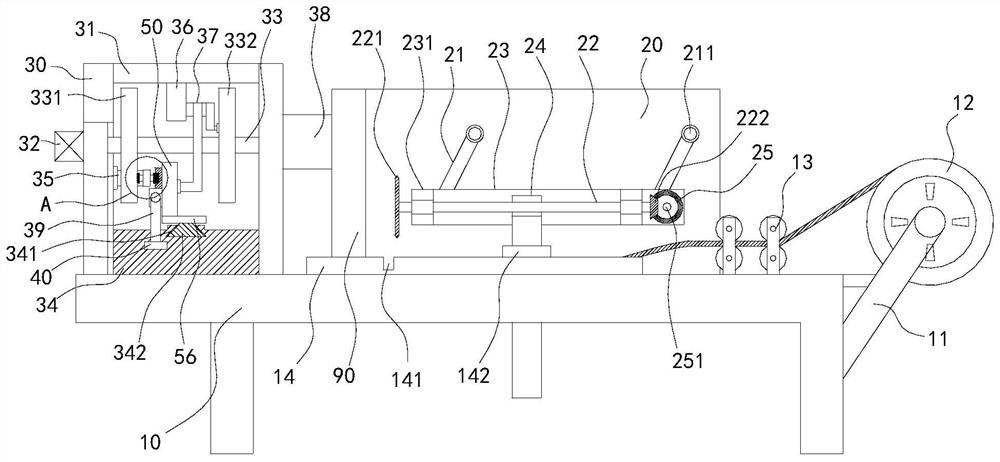

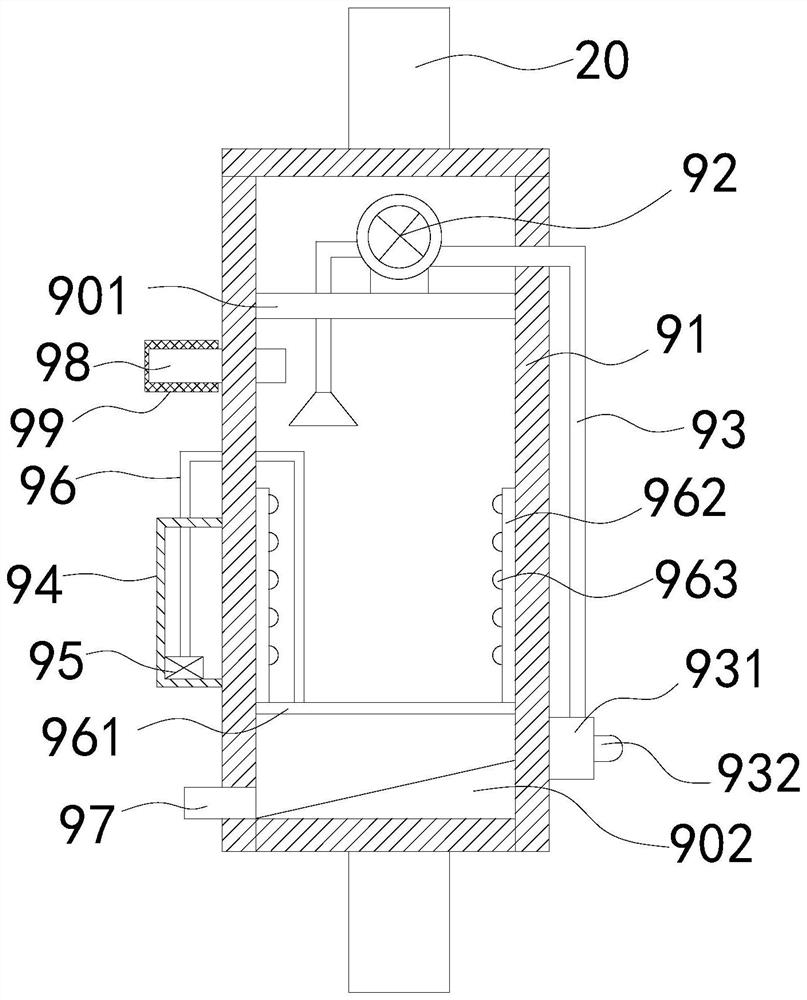

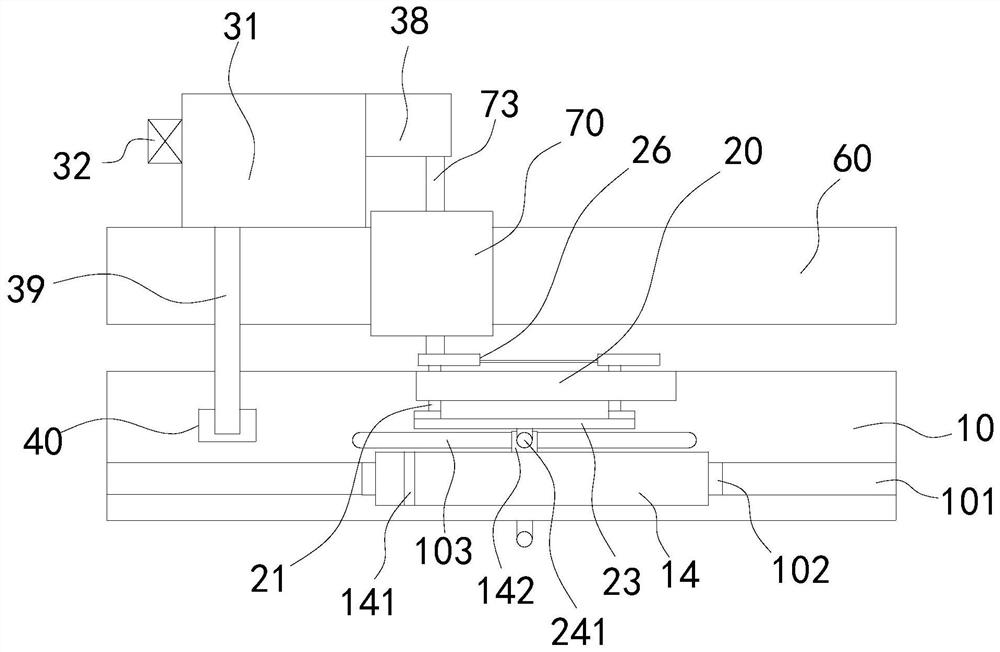

[0039] Such as Figure 1-16 As mentioned above, the present invention provides a dust treatment device in a recycled plastic granule processing workshop, which includes:

[0040] The working platform 10, the right side wall of the working platform 10 is provided with a fixed frame 11, the fixed frame 11 is provided with a winding cylinder 12, the left side of the winding cylinder 12 is provided with a feed roller 13, and the upper surface of the working platform 10 is provided with a guide Slot 101, sliding block 102 is arranged in guide groove 101, and feed plate 14 is arranged laterally on the top of slide block 102, and the outer wall of feed plate 14 is provided with limit ring 142, and one side of guide groove 101 corresponds to limit ring 142. The bottom is provided with strip holes 103 in parallel;

[0041] Section cutting mechanism, the section cutting mechanism is arranged on the inner side of the working platform 10, the section cutting mechanism includes a board bo...

Embodiment 2

[0052] Such as Figure 1-16 As shown, the present invention provides a dust treatment device in a recycled plastic granule processing workshop, which device includes:

[0053] The working platform 10, the right side wall of the working platform 10 is provided with a fixed frame 11, the fixed frame 11 is provided with a winding cylinder 12, the left side of the winding cylinder 12 is provided with a feed roller 13, and the upper surface of the working platform 10 is provided with a guide Slot 101, sliding block 102 is arranged in guide groove 101, and feed plate 14 is arranged laterally on the top of slide block 102, and the outer wall of feed plate 14 is provided with limit ring 142, and one side of guide groove 101 corresponds to limit ring 142. The bottom is provided with strip holes 103 in parallel;

[0054] Section cutting mechanism, the section cutting mechanism is arranged on the inner side of the working platform 10, the section cutting mechanism includes a board body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com